- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Dedicated temperature sensor for lithium battery drying equipment, Pt1000.DW.M500.2040.B.PN

Dedicated temperature sensor for lithium battery drying equipment, Pt1000.DW.M500.2040.B.PN

Industry Sector: New energy lithium battery manufacturing

Breakthrough in core pain points

In the production of lithium batteries, the high-temperature drying process demands extremely precise temperature control (within ±0.5℃). Traditional sensors, due to issues such as large size, slow response, and insufficient temperature resistance, are prone to causing solvent residue on the electrode sheets or thermal damage to the separator, directly affecting battery safety and consistency.

In-depth analysis of technical parameters

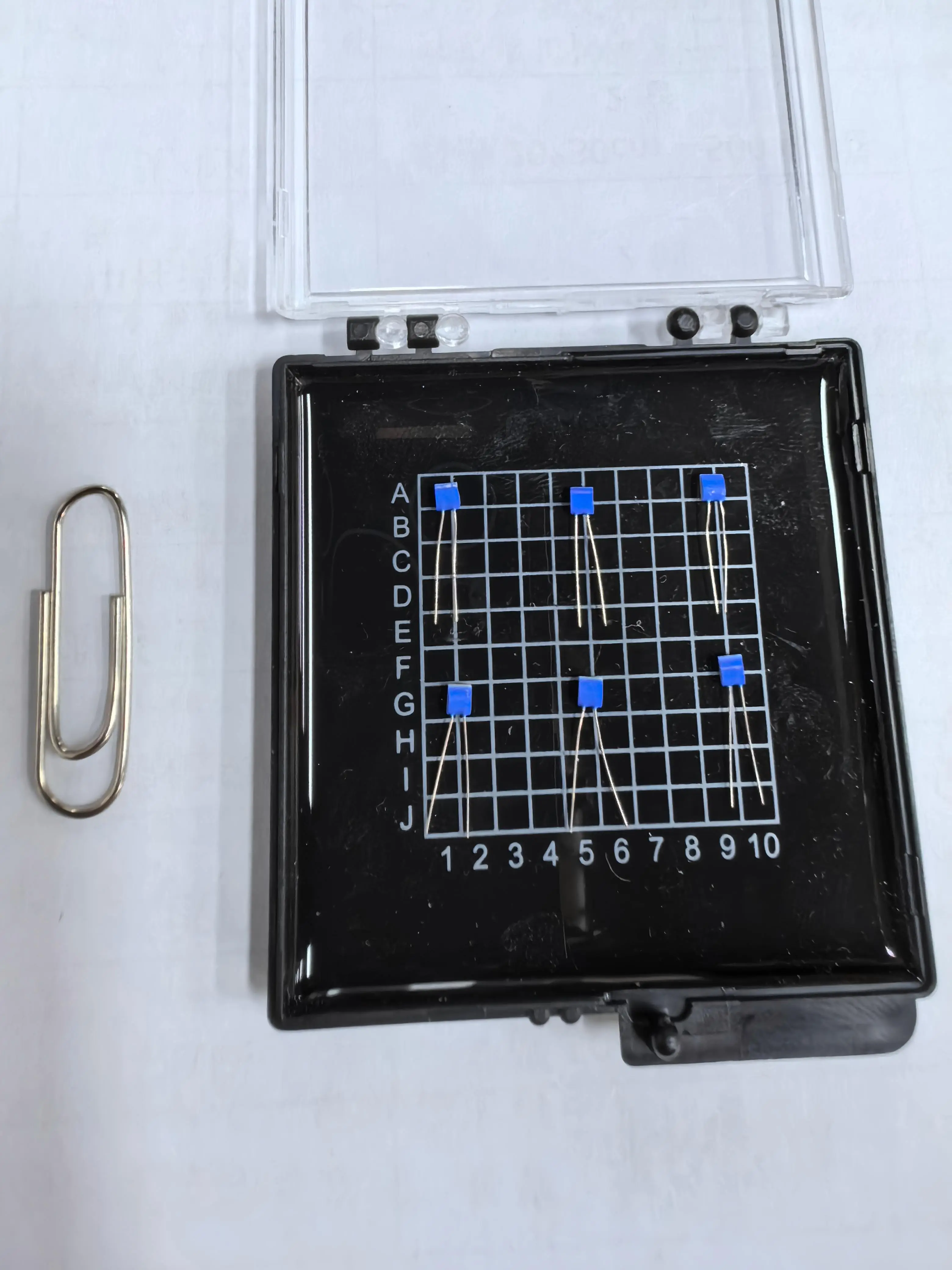

1. Micro-scale precision structures

2.0×4.0×1.0mm ultra-thin size: It can be embedded into narrow spaces that are inaccessible to traditional sensors, such as gaps in drying rollers and interlayers in vacuum chambers, to avoid airflow interference.

316L stainless steel + alumina ceramic packaging: resistant to NMP solvent corrosion and vacuum environment, with a lifespan increased by 3 times.

2. Performance under extreme operating conditions

-70~+500℃ wide temperature range coverage:

Low temperature section (-70℃): compatible with electrolyte freeze-drying process

High temperature section (500℃): meets the curing requirements of high nickel ternary materials

Accuracy of ±(0.3+0.005|t|)℃:

The measured error under 300℃ operating conditions is ≤±1.2℃, ensuring that the moisture content of the electrode plate remains stable within 50ppm.

3. Dynamic response advantage

0.1 second water flow response speed: real-time tracking of temperature fluctuations in hot air circulation to prevent local overheating and diaphragm contraction (measured temperature fluctuation suppression rate of 92%).

Platinum-nickel alloy lead wire: shock resistance ≥40g, suitable for vibration environments of high-speed rolling equipment.

Solutions for three core application scenarios

**► Pole piece coating and drying line**

Pain point: Residual solvent caused by temperature difference between layers inside the coating oven

Plan:

Dense sampling points are arranged in the hot air circulation zone at 120-150℃, with micro probes directly contacting the surface of the pole pieces.

Achievement: The residual NMP content of a certain customer has been reduced from 800ppm to 150ppm, resulting in an 18% reduction in drying energy consumption.

**► Battery cell vacuum drying chamber**

Pain point: Traditional sensors experience severe drift in a vacuum environment

Plan:

It is installed on the side wall of the cabin using flanges, and is equipped with an anti-negative pressure sealing design (vacuum degree ≤100Pa).

Achievements: The accuracy of moisture content control has reached (100±20)×10⁻⁶, and the pass rate of liquid injection has been increased to 99.3%.

**► High-temperature curing line**

Pain point: Oxidation failure of leads due to high temperature of 400℃

Plan:

The structure of platinum-nickel lead + ceramic insulation layer exhibits a resistance drift of less than 0.04% after continuous high-temperature operation for 1000 hours.

Achievements: The sintering temperature difference of high-nickel cathode materials has been compressed from ±5℃ to ±1.8℃, resulting in a 40% reduction in battery internal resistance dispersion.

Industry empirical case

A base of CATL

Deploy 32 monitoring points in the 200PPM high-nickel ternary electrode production line:

The drying cycle has been shortened from 12 hours to 10.2 hours

The standard deviation of the moisture content in the electrode plate has been reduced from 35ppm to 8ppm

The battery cycle life has been increased from 2000 times to 2240 times

Solid-state battery R&D project

For drying sulfide electrolyte (in an argon atmosphere at 200℃):

After 1000 hours of continuous operation, the zero drift is only 0.018Ω

The fluctuation range of electrolyte ion conductivity has been narrowed to ±3%

Advanced Selection Guide

1. Conventional drying line

Recommended model: Pt1000.DW.M500.2040.B.PN

Key features: Standard flange interface, compatible with rake dryer/rotary kiln

2. Ultra-high temperature process (>400℃)

Upgrade plan: Pt1000.DW.M500.2040.AP

Core upgrade: Silver-palladium lead wire + vacuum brazing, capable of withstanding instantaneous high temperatures up to 850℃

3. Inert gas environment

Special version: Pt1000.DW.M500.2040.B.PT

Unique technology: Anti-reducing gas coating, suitable for hydrogen atmosphere drying

Technology empowers value

By elevating the temperature control accuracy to the industrial-grade limit, this sensor assists customers in:

Reduce drying energy consumption by 22%

Reduce the battery self-discharge rate by 5%

Increase production density by 18%

Through nanoscale packaging technology and military-grade stability design, this product has become a benchmark for precision in the drying process of power batteries, providing core temperature control support for the world's TOP 10 battery companies.

Learn about our latest products and discounts through SMS or email