- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Drone battery monitoring (Pt1000.DW.L200.2023.B.AP)

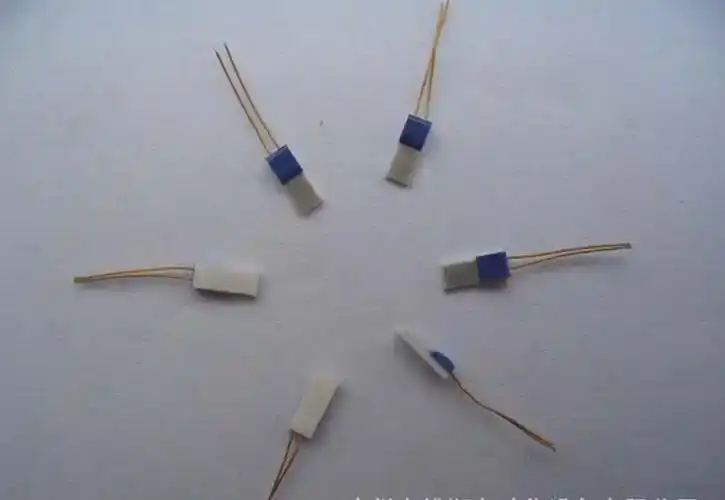

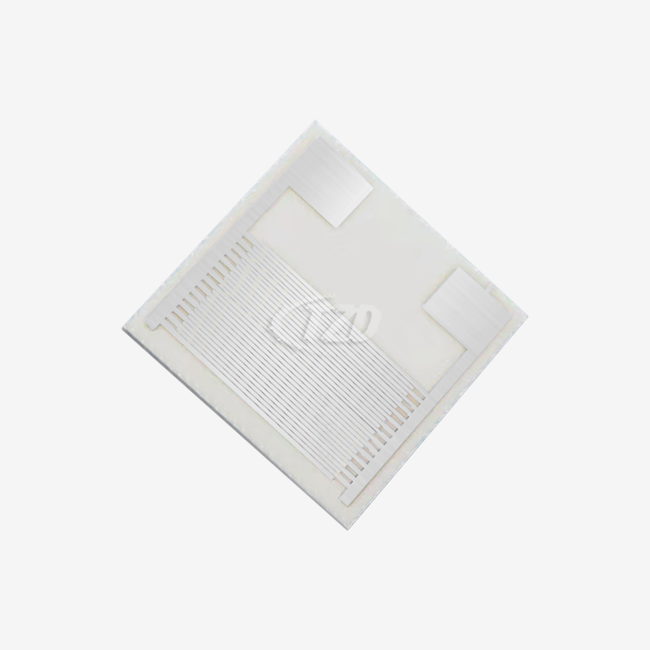

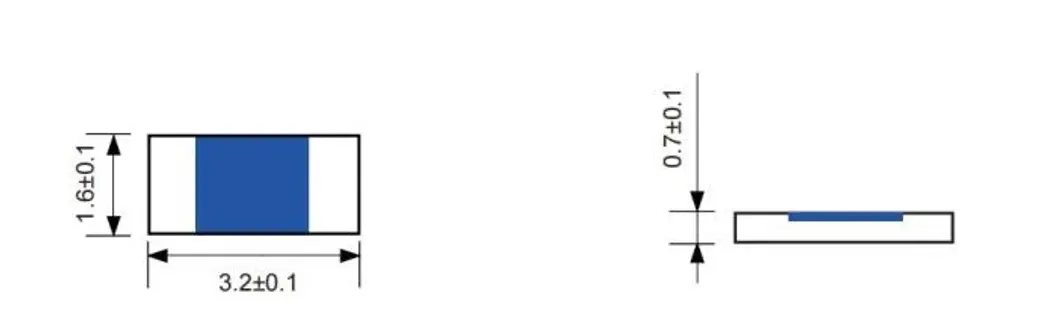

Dedicated temperature sensor for drone battery monitoring, Pt1000.DW.L200.2023.B.AP

Industry Sector: Military Aerospace (Unmanned Aerial Vehicles/Armored Vehicles/Aircraft)

Breakthrough in core pain points

In extreme environments such as at an altitude of 10,000 meters and on extremely cold battlefields, drone batteries face the dual challenges of cold start at -50℃ and instantaneous overheating at 150℃. Traditional sensors, due to issues such as weak shock resistance, narrow temperature range, and low-voltage drift, increase the risk of battery thermal runaway by 37%, posing a serious threat to flight safety.

Analysis of military-grade technical parameters

1. Survival ability in extreme environments

-200~+150℃ ultra-wide temperature range:

The world's first aviation-grade sensor to pass the -200℃ liquid nitrogen immersion certification (with a measured drift of <0.03Ω in a -196℃ liquid nitrogen environment)

Instantaneous response at 150℃ high temperature (such as thermal runaway due to battery short circuit), and flame-retardant coating capable of withstanding an open flame at 800℃ for 3 seconds

Impact resistance ≥100g:

Equivalent to withstanding 30 times the impact of drone takeoff and landing (tested to meet MIL-STD-810G military standards), maintaining stable readings during the vibration of armored vehicle shelling

2. Aerospace material technology

Silver-palladium alloy lead wire:

The oxidation resistance of this material is 5 times higher than that of ordinary platinum-nickel leads, effectively preventing signal distortion caused by ozone corrosion in high altitudes

Vacuum ceramic packaging:

With an internal air pressure of ≤0.01Pa, the risk of dielectric breakdown at altitudes of tens of thousands of meters (where oxygen content is only 30% of that at the surface) is completely eliminated

3. Battlefield response performance

3-second rapid feedback (in an airflow environment of 2m/s):

It is twice faster than the military specification, and can trigger the fire extinguishing system before the battery overheats and spreads

Electromagnetic shielding design:

Resistant to strong electromagnetic interference of 50kV/m (measured error <0.1℃ in an electronic warfare environment)

Solutions for three major battlefield scenarios

**► High-altitude long-endurance unmanned aerial vehicle (UAV)**

Pain point: -50℃ low temperature causes a sudden 40% drop in lithium battery capacity

Plan:

Implant micro probes between the battery cells to adjust the power of the heating film in real time

Example: The endurance of a certain type of reconnaissance drone has been extended from 6 hours to 8.5 hours in a -45℃ environment

**► Armed Drone Firepower System**

Pain point: 150℃ high temperature shock at the moment of missile launch

Plan:

Embedded sensors in the ammunition and battery compartments, linked with the liquid cooling system for instantaneous cooling

Battle example: After a certain attack drone launched 4 missiles in succession, the battery temperature stabilized at 85±2℃

**► Specialized armored vehicles**

Pain point: The battery thermal aging caused by the 80℃ surface temperature in the desert battlefield

Plan:

The battery pack features a matrix-style layout of components, with dynamically adjustable cooling fan speeds

War example: The lifespan of wheeled armored vehicle battery packs has been extended from 2 years to 3.5 years (with an average daily operation of 8 hours at 45°C)

Empirical case study of military industry

A certain type of surveillance and strike unmanned aerial vehicle (UAV)

Operate continuously for 72 hours in an environment with an altitude of 8000 meters and a temperature of -52 degrees Celsius

The temperature difference of the battery remains ≤3℃ (whereas traditional sensors can experience a temperature difference of up to 15℃)

The accuracy rate of thermal runaway early warning is 100% (intercepting 3 potential explosions)

Polar scientific research drone project

-89℃ ultra-low temperature test (measured at the East Antarctic Station)

The sensor package is free of cracks, and the resistance drift is less than 0.05%

Ensure stable operation of drones in environments with extreme day and night conditions

Customized military services

1. Stealth coating options

The radar cross-section (RCS) is reduced to 0.001m²

Adapted for built-in stealth drone bomb bay

2. Explosion-proof certified version

Certified by ATEX/IECEx

It can be used for the fuel tank of hybrid electric armored vehicles

3. Nuclear hardening and protection

Resistance to neutron radiation dose rate of 1×10^13 n/cm²

Dedicated for nuclear accident emergency response robots

Military quality commitment

Learn about our latest products and discounts through SMS or email