- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

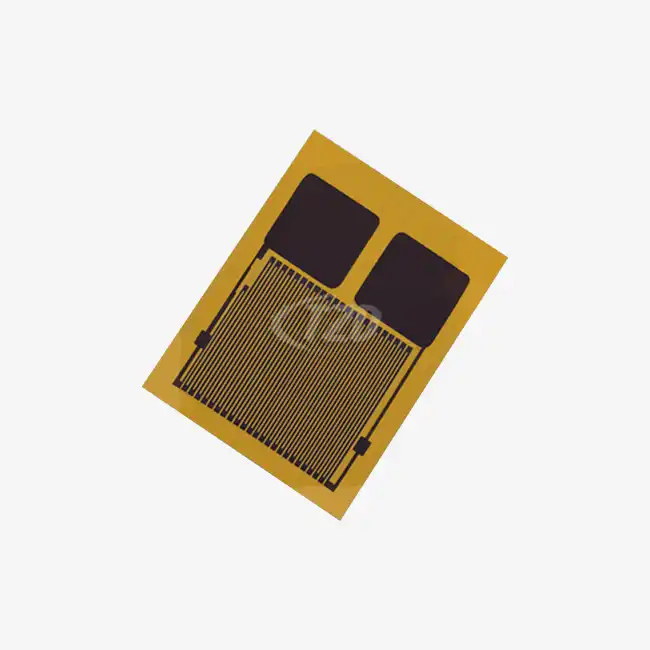

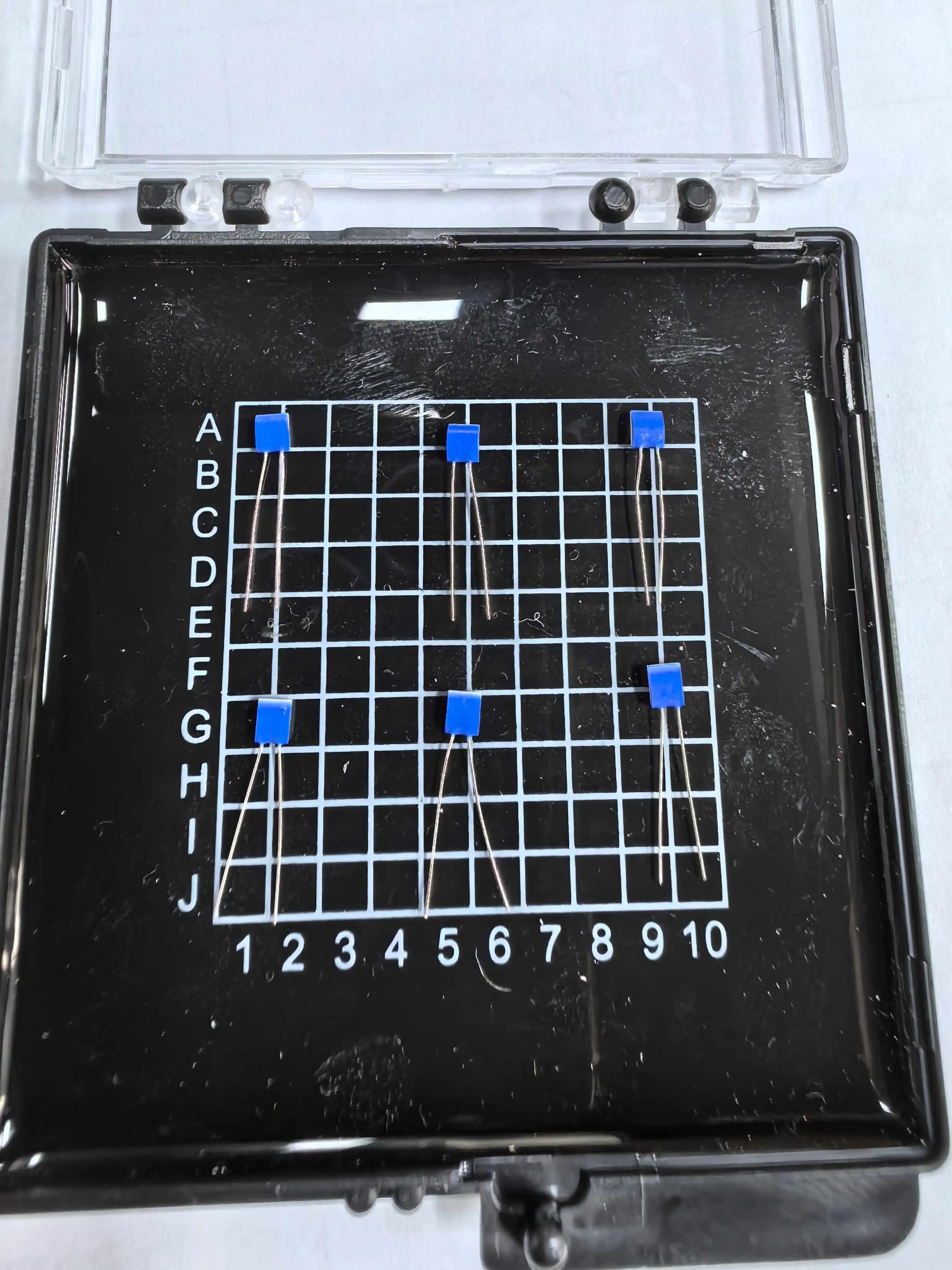

Pt100 Sensor

Element Dimensions:3.2mm x 1.6mm x 0.7mm

Temperature Coefficient (TCR):3850 ppm/°C

Teperature Measurement Range:-50°C to +200°C

Long-Term Stability:≤±0.06% resistance drift of R₀°C after 1000 hours at 200°C

Terminal Type:Tin alloy terminals

Soldering Method:Reflow soldering or wave soldering. High-temperature solder paste recommended.

Soldering temperature: 230-240°C

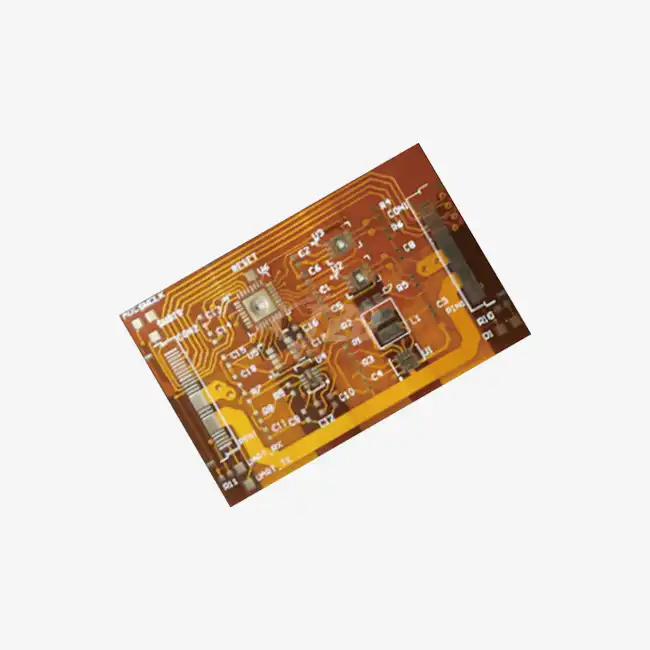

Pt100 Sensor Manufacturer And Supplier

Xi'an Tongzida Technology Co., Ltd. is a leading Pt100 Sensor manufacturer & supplier, specializing in high-performance thin film platinum resistance thermistors. With ISO 9001, CE, and RoHS certifications, our sensors deliver unmatched accuracy (±0.01 Ω), stability (≤0.04% drift), and durability for demanding industries like aerospace and automotive.

Why Choose Our Pt100 Sensor?

Trusted by global OEMs and system integrators, our sensors excel in harsh environments. Key advantages:

- IEC 60751 compliance with 3850 ppm/°C TCR: Our product adheres to the exacting IEC 60751 standard, featuring a 3850 ppm/°C temperature coefficient of resistance (TCR). This ensures precise and consistent temperature sensing, making it a reliable choice for applications demanding accuracy.

- Wide temperature range (-200°C to +850°C): Engineered to perform across an expansive -200°C to +850°C temperature spectrum, our solution can withstand extreme cold and searing heat. It's suitable for a multitude of environments, from cryogenic labs to high - temperature industrial settings.

- Customizable sizes (1.2mm–4.0mm) and lead materials (platinum nickel, silver nickel): Recognizing diverse needs, we offer customizable options. Select sizes between 1.2mm–4.0mm and choose lead materials like platinum nickel or silver nickel, tailoring the product to fit your specific application requirements.

- Fast response (0.05 seconds) and vibration resistance (100g impact): With a rapid 0.05 - second response time, our product enables immediate data capture. Additionally, it can endure 100g impacts, ensuring reliable performance even in high - vibration, harsh conditions.

Pt100 Sensor Specifications

| Parameter | Details |

|---|---|

| Element Type | SMD Thin Film Platinum Resistance |

| Dimensions | 3.2mm x 1.6mm x 0.7mm |

| Temperature Coefficient | 3850 ppm/°C |

| Measurement Range | -50°C to +200°C |

| Long-Term Stability | ≤±0.06% drift after 1000h at 200°C |

| Terminals | Tin alloy (reflow/wave soldering ready) |

Reference Selection Guide

| Application | Recommended Model | Key Benefit |

|---|---|---|

| Industrial Machinery | TD-Pt100-3.2A | High vibration resistance |

| Medical Equipment | TD-Pt100-2.0M | Ultra-low drift for accuracy |

| Automotive Systems | TD-Pt100-4.0C | Wide temperature tolerance |

Key Features of Our Pt100 Sensor

- Precision Engineering: Achieve 1/30B accuracy for critical processes.

- Robust Design: Withstand extreme temperatures, shocks, and corrosive conditions.

- Fast Integration: Compatible with reflow soldering (230–240°C).

- Global Compliance: Meet ATEX, ASTM E1137, and industry-specific standards.

Pt100 Sensor Applications

Ideal for:

- HVAC Systems: Monitor airflow and equipment health.

- Pharmaceuticals: Ensure sterile process control.

- Renewable Energy: Optimize solar/wind turbine performance.

- Aerospace: Reliable data in high-pressure environments.

Certifications & Quality Assurance

Our Pt100 Sensor stands as a paragon of quality and reliability, fully compliant with the prestigious ISO 9001, CE, and RoHS standards. The ISO 9001 certification attests to our unwavering commitment to maintaining a robust quality management system throughout the manufacturing process. The CE mark confirms its adherence to strict European health, safety, and environmental protection regulations, while RoHS compliance underscores our dedication to using only environmentally friendly materials. Through rigorous testing procedures, we ensure that the sensor exhibits an incredibly low drift of less than 0.04% even after enduring 5,000 cycles, guaranteeing consistent and accurate performance over extended periods of use in diverse applications.

Packing & Delivery

Our sensors are carefully vacuum-sealed within specialized anti-static packaging, providing a dual layer of protection. The anti-static feature shields the sensitive components from electrostatic discharge, which can potentially damage the intricate circuitry. Meanwhile, the vacuum-sealing creates an airtight environment, safeguarding the sensors from moisture, dust, and oxidation during transit. For bulk orders, we have streamlined our logistics process to ensure rapid global shipping. Leveraging a network of reliable carriers, we can deliver your large-scale orders to destinations around the world within just 5–7 days, minimizing downtime and ensuring your production schedules stay on track.

FAQ

Q1: Can you customize lead lengths for OEM integrations?

Yes! Specify length, material (pure platinum/nickel alloy), and connector types.

Q2: What's the minimum order quantity?

No MOQ—ideal for prototyping or large-scale production.

Q3: How do you ensure long-term stability?

Our thin film design minimizes oxidation, backed by 1,000-hour stress tests.

Q4: Do you support vacuum packaging?

Absolutely. Request hermetic sealing for ultra-low temperature use.

Q5: What's your lead time for 10,000 units?

Just 10–14 days with priority production scheduling.

Contact us

Need a Pt100 Sensor tailored to your project? Contact our engineers at sales11@xatzd.com for samples, quotes, or technical support.

Learn about our latest products and discounts through SMS or email