- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

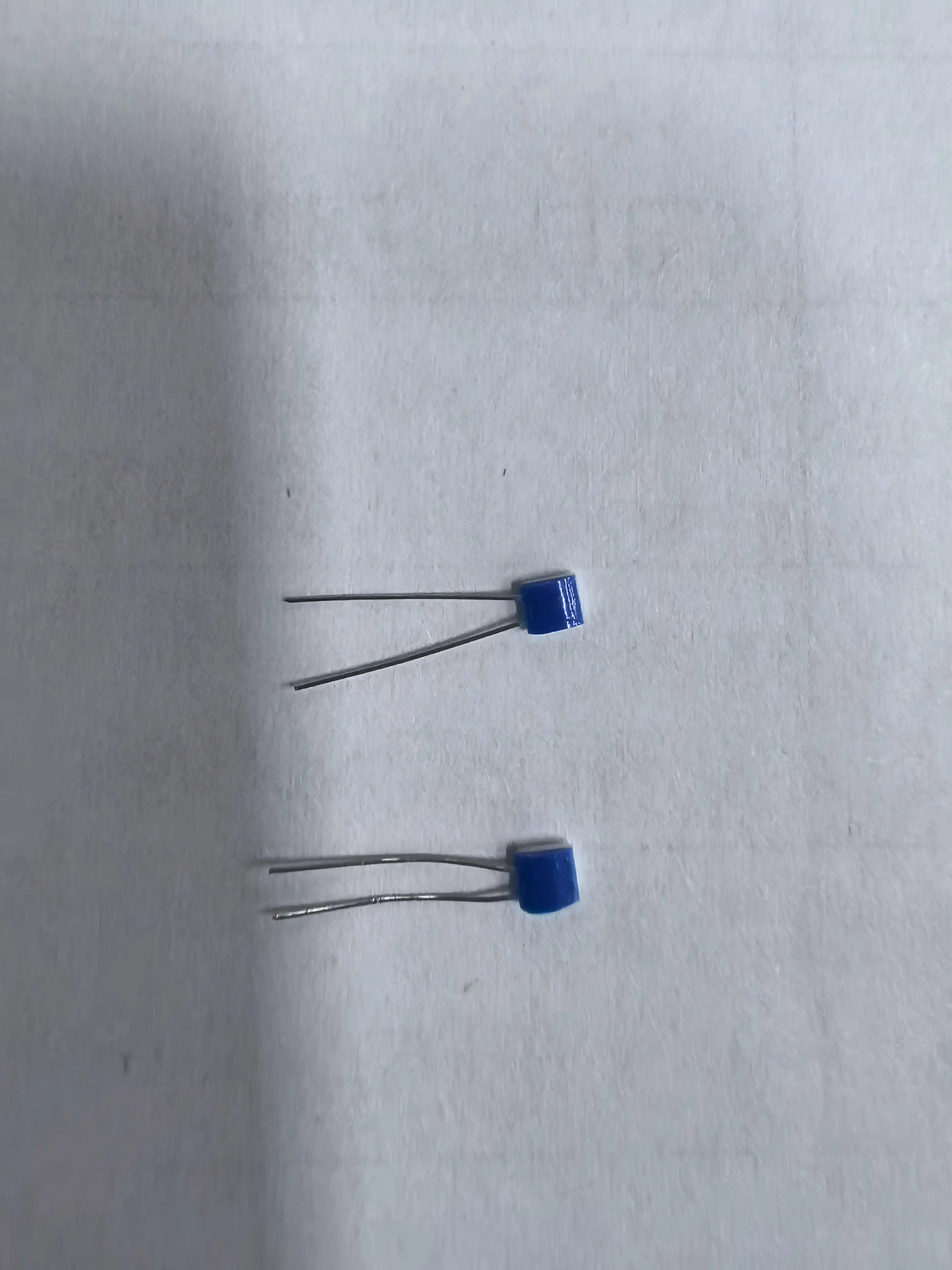

Platinum RTD Sensor

Element Dimensions:2.0mm x 2.3mm x 1.0mm,1.6mm x 2.0mm x 1.0mm,1.2mm x 2.0mm x 1.0mm

Lead Specifications:Length: 10 mm,Diameter: 0.2 mm

Lead Material: Platinum-nickel wire (optional: silver-palladium/platinum/silver-nickel)

Lead Tensile Strength:≥9 N

Insulation Resistance:100 MΩ at 20°C, >2 MΩ at 500°C

Temperature Coefficient (TCR):3850 ppm/°C

Operating Current:0.3 ~ 1 mA (self-heating effect to be considered)

Long-Term Stability:≤±0.04% resistance drift after 1000 hours at 500°C

Response Time:Flow (V=0.4 m/s):t0.5 = 0.05 s,t10 = 0.15 s;Airflow (V=2 m/s):t0.5 = 3 s,t10 = 10 s

Self-Heating Coefficient:0.4°C/mW

Vibration Resistance:≥40g acceleration (10 ~ 2000 Hz frequency range)

Shock Resistance:≥100g acceleration (8 ms half-sine wave)

Packaging:Vacuum plastic packaging (other packaging formats available upon request)

Your Trusted Platinum RTD Sensor Manufacturer And Supplier

Xi'an Tongzida Technology Co., Ltd. is a leading Platinum RTD Sensor manufacturer and supplier, specializing in advanced thin-film technology. With ISO 9001, CE, and RoHS certifications, we deliver sensors renowned for accuracy (±0.01 Ω), durability (40g vibration resistance), and compliance with IEC 60751 standards. Our automated production ensures consistency, while customizable designs meet diverse industrial needs.

Why Choose Our Platinum RTD Sensors?

3850 ppm/°C TCR: Boasting an industry - leading temperature coefficient of resistance (TCR) of 3850 ppm/°C, it offers unparalleled sensitivity to temperature changes for precise measurements. Wide Range: Designed to perform flawlessly, it can operate across an expansive temperature spectrum, ranging from the extreme cold of -200°C to the intense heat of +850°C. Certified Quality: Through rigorous testing procedures, it ensures long - term stability with a minimal ≤0.04% drift, guaranteeing consistent and reliable performance over time. Tailored Solutions: We provide customizable options including sizes from 1.2mm–4.0mm and a choice of lead materials like platinum - nickel and silver - palladium to meet specific application needs.

Specifications at a Glance

| Parameter | Details |

|---|---|

| Element Dimensions | 2.0mm x 2.3mm x 1.0mm, 1.6mm x 2.0mm x 1.0mm, 1.2mm x 2.0mm x 1.0mm |

| Lead Material | Platinum-nickel (default); optional silver-palladium, pure platinum |

| Temperature Coefficient | 3850 ppm/°C (IEC 60751 compliant) |

| Response Time | 0.05s (flow), 3s (airflow) |

| Shock Resistance | 100g acceleration (8ms half-sine wave) |

Reference Selection Guide

| Model | Size | Temp Range | Best For |

|---|---|---|---|

| TZ-PRT-2.0 | 2.0mm x 2.3mm | -200°C to +500°C | Medical devices, HVAC systems |

| TZ-PRT-1.6 | 1.6mm x 2.0mm | -100°C to +850°C | Automotive testing, aerospace sensors |

| TZ-PRT-1.2 | 1.2mm x 2.0mm | -200°C to +300°C | Lab equipment, precision instruments |

Key Features of Our Platinum RTD Sensors

- Ultra-Fast Response: Achieve real-time monitoring with 0.05s reaction in flow environments.

- Robust Build: Withstand 40g vibrations and 100g shocks for harsh industrial settings.

- Low Self-Heating: 0.4°C/mW ensures minimal interference in sensitive applications.

- Vacuum Packaging: Optional sealing for contamination-prone environments.

Where Our Platinum RTD Sensors Excel

- Industrial: Monitor chemical reactors or metal furnaces.

- Healthcare: Sterilize medical devices with precision.

- Automotive: Test engine performance under extreme conditions.

- Energy: Safeguard turbines in power plants.

Certifications & Compliance

Our Platinum RTD Sensors are engineered with an unwavering commitment to excellence, ensuring strict compliance with ISO 9001, RoHS, and CE standards. The ISO 9001 certification validates our robust quality management system, while RoHS compliance confirms our dedication to minimizing hazardous substances, safeguarding both users and the environment. The CE mark attests to meeting stringent European health, safety, and environmental protection requirements. To uphold these high - standards, our comprehensive quality control process involves 100% batch testing. Every batch undergoes thorough assessments of insulation resistance to ensure electrical safety and TCR accuracy to guarantee reliable temperature sensing, ensuring each sensor meets the highest performance benchmarks.

Packing & Delivery

To ensure the utmost protection of our sensors, each unit is meticulously vacuum-sealed. This specialized packaging creates an airtight barrier that safeguards against moisture, dust, and other contaminants, preserving the integrity and functionality of the sensors during transit. For customers placing bulk orders, we offer a reliable and efficient shipping solution. Leveraging the extensive networks of renowned carriers DHL and FedEx, we guarantee that large shipments will be dispatched within 7–10 days. Our streamlined logistics process ensures that your bulk orders reach their destination promptly and in perfect condition, providing you with peace of mind and timely access to the products you need.

FAQs

Q: Can I request non-standard lead lengths?

A: Yes! Custom lead lengths (5mm–50mm) are available.

Q: Are your sensors ATEX-certified?

A: We offer ATEX-compliant options for hazardous environments.

Q: What's the minimum order quantity?

A: MOQ starts at 100 units, with discounts for 500+ orders.

Q: Do you provide calibration certificates?

A: Traceable NIST certificates are included with every order.

Q: How do I integrate these sensors into existing systems?

A: Our team offers free technical support for seamless integration.

Empower Your Systems with Precision

Need a Platinum RTD Sensor that combines reliability and customization? Contact us at sales11@xatzd.com for tailored quotes or technical guidance. Let's build smarter solutions together!

Learn about our latest products and discounts through SMS or email