- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

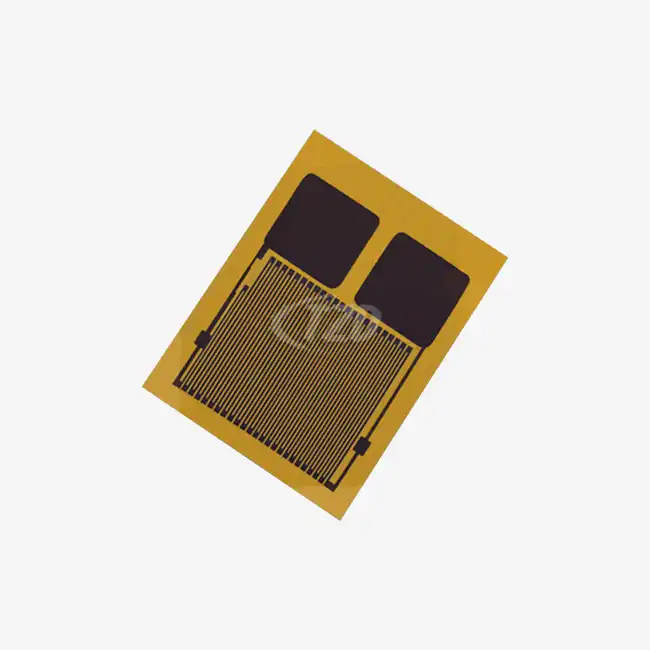

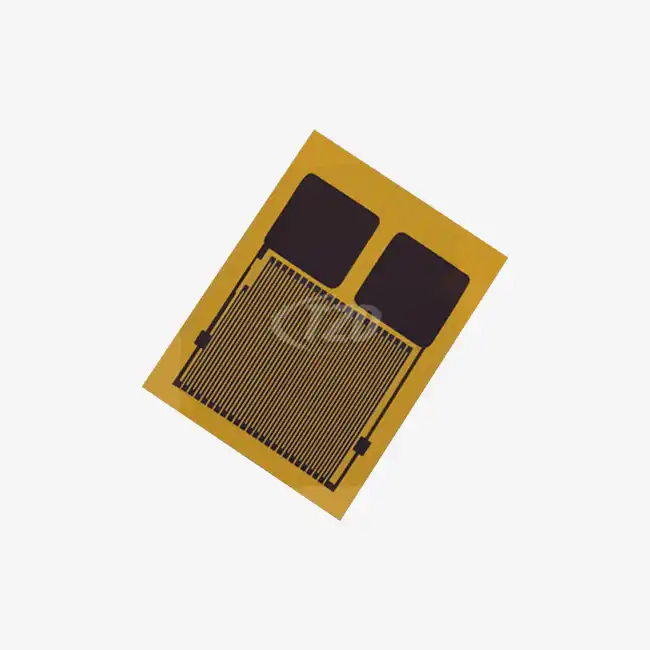

Pt100 Thin Film Element

Element Dimensions:3.2mm x 1.6mm x 0.7mm

Temperature Coefficient (TCR):3850 ppm/°C

Temperature Measurement Range:-50°C to +200°C

Long-Term Stability:≤±0.06% resistance drift of R₀°C after 1000 hours at 200°C

Terminal Type:Tin alloy terminals

Soldering Method:Reflow soldering or wave soldering. High-temperature solder paste recommended.

Soldering temperature: 230-240°C

Pt100 Thin Film Element Manufacturer And Supplier

As a leading Pt100 Thin Film Element manufacturer, we combine advanced thin-film chip design, IEC 60751 compliance, and automated production to deliver sensors with unmatched stability (±0.06% drift) and durability (100g impact resistance). Our IS09001, CE, and RoHS certifications ensure quality for industrial, automotive, and medical applications.

Why Choose Our Pt100 Thin Film Element?

- Precision Performance: Engineered to perfection, our product delivers outstanding precision, achieving ±0.01 Ω accuracy at the 1/30B level. It maintains this high - level accuracy consistently across a wide temperature range from -50°C to +200°C, ensuring reliable measurements in diverse conditions.

- Long-Term Reliability: Built for endurance, our solution offers remarkable long - term reliability. Even after 1,000 hours of operation at 200°C, it experiences a minimal ≤0.06% resistance drift, guaranteeing stable performance over extended periods.

- Custom Solutions: Understanding that one size doesn't fit all, we provide customizable options. You can choose lead materials like platinum nickel or silver nickel, select sizes between 1.2mm–4.0mm, and customize the encapsulation to meet your specific application needs.

- Harsh Environment Ready: Designed to thrive in tough settings, our product can withstand intense 40g vibrations. Coupled with an incredibly rapid 0.05s response time, it ensures reliable and immediate data acquisition, making it ideal for demanding, high - stress environments.

Specifications

| Parameter | Details |

|---|---|

| Dimensions | 3.2mm x 1.6mm x 0.7mm |

| Temperature Coefficient | 3850 ppm/°C (IEC 60751 compliant) |

| Measurement Range | -50°C to +200°C |

| Long-Term Stability | ≤±0.06% drift after 1,000h at 200°C |

| Terminals | Tin alloy (high-temperature solder compatible) |

| Soldering Method | Reflow/Wave soldering (230–240°C) |

Reference Selection Guide

| Part No. | TCR (ppm/°C) | Temperature Range | Lead Material |

|---|---|---|---|

| TZ-PT101 | 3850 | -50°C to +200°C | Platinum Nickel |

| TZ-PT102 | 3850 | -100°C to +300°C | Pure Platinum |

Key Features of Our Pt100 Thin Film Element

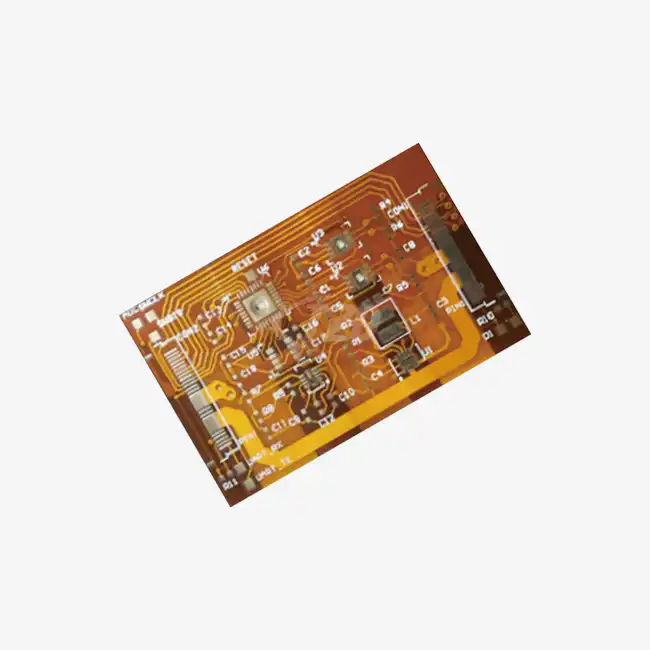

- Optimized for Automation: Compatible with reflow/wave soldering for high-speed PCB assembly.

- Medical-Grade Stability: Minimal drift ensures accuracy in sterilization systems and diagnostic tools.

- Automotive Durability: Survives engine vibrations and EV battery thermal shocks.

- Vacuum-Sealed Options: Ideal for aerospace and semiconductor fabrication.

Applications

- Industrial: Process control, HVAC monitoring, and energy grid sensors.

- Automotive: EV battery management, exhaust gas recirculation.

- Medical: Lab equipment, sterilization autoclaves.

- Electronics: Semiconductor testing, data center cooling systems.

Certificates

Our Pt100 Thin Film Element stands as a testament to unparalleled quality and compliance, meticulously crafted to meet the exacting standards of ISO 9001, CE, RoHS, and IATF 16949. The ISO 9001 certification validates our robust quality management system, ensuring consistent manufacturing excellence. The CE mark confirms that our product adheres to strict European health, safety, and environmental protection regulations. RoHS compliance reflects our commitment to using only environmentally friendly materials, eliminating hazardous substances from the production process. IATF 16949 certification, specific to the automotive industry, showcases our ability to deliver products that meet the stringent requirements of automotive manufacturing, guaranteeing reliability and performance across diverse applications.

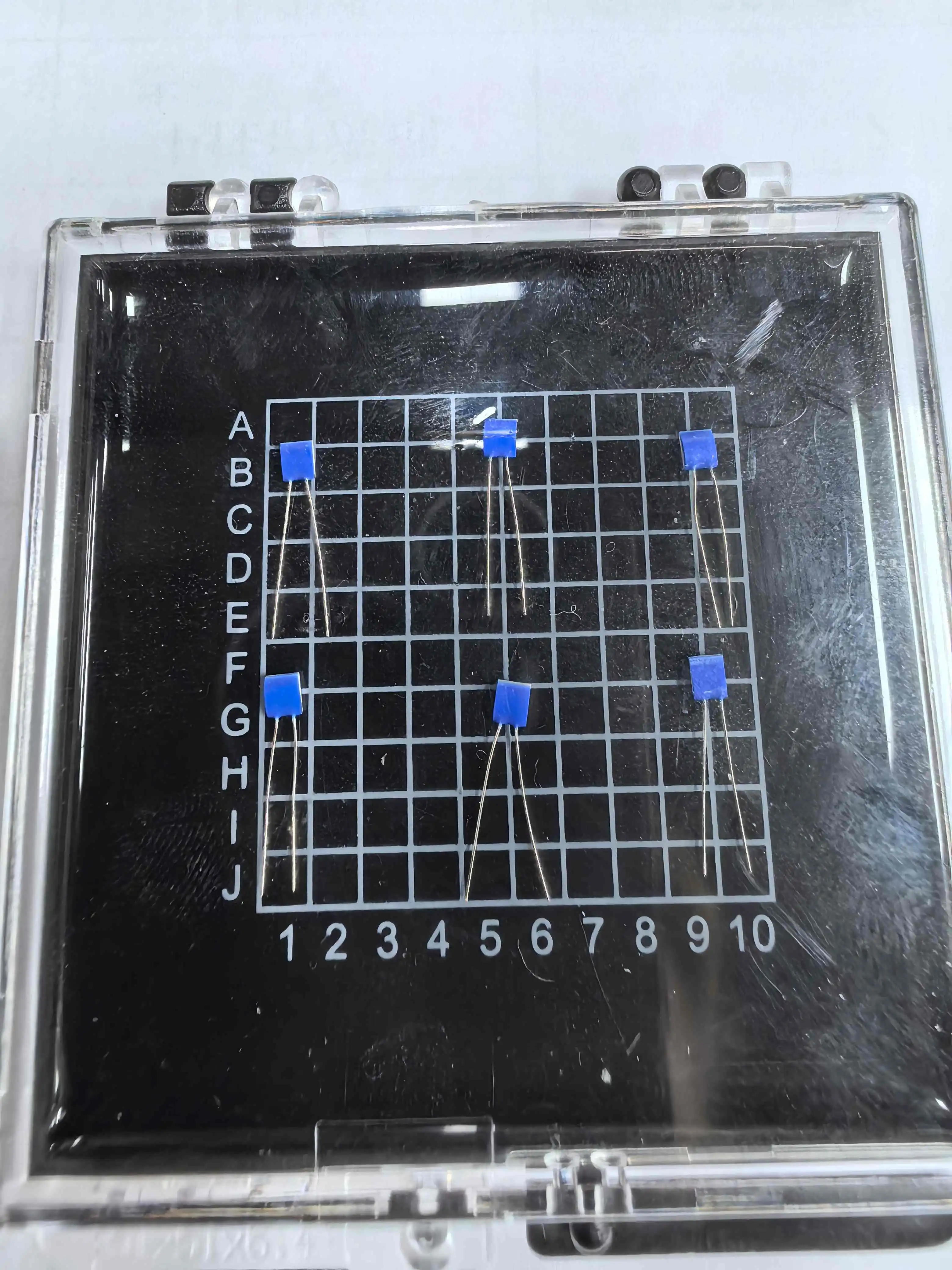

Packing and Delivery

Our sensors are carefully placed in anti-static trays and then vacuum-sealed, providing dual protection. The anti-static trays safeguard the sensors from electrostatic discharge, which can damage sensitive electronic components. The vacuum-sealing process creates an airtight barrier, shielding the sensors from moisture, dust, and other contaminants during transit. Leveraging an extensive global shipping network, we ensure that these well-protected sensors reach customers worldwide within just 5–7 days. This efficient shipping schedule minimizes downtime and allows businesses to quickly integrate our sensors into their operations.

FAQ

- Q: Can you customize lead lengths for legacy systems?

A: Yes! We offer tailored leads (1mm–50mm) to fit your existing setups. - Q: What's the MOQ for bulk orders?

A: No strict MOQ – we scale from prototypes to 10,000+ units. - Q: Do you provide ISO 13485-certified sensors?

A: Absolutely. Ask our team for medical/automotive certification packages. - Q: How do I calibrate these sensors?

A: We share step-by-step calibration guides and offer on-site support. - Q: Are volume discounts available?

A: Yes. Contact us for tiered pricing based on annual forecasts.

Contact Us

Need a Pt100 Thin Film Element that outperforms competitors? Email sales11@xatzd.com for datasheets, samples, or custom quotes.

Learn about our latest products and discounts through SMS or email