- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

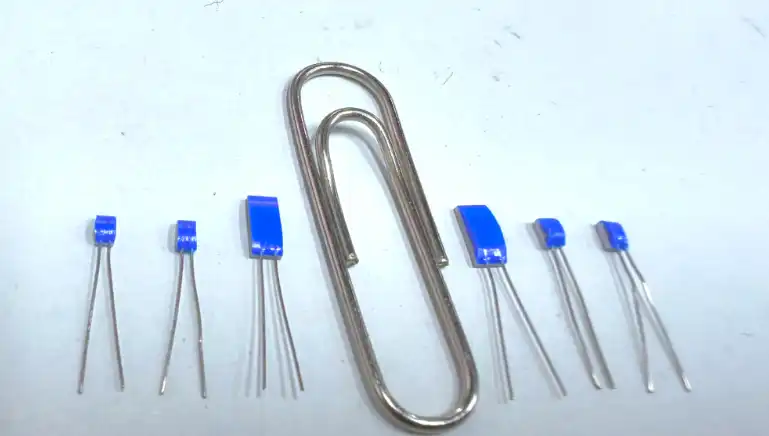

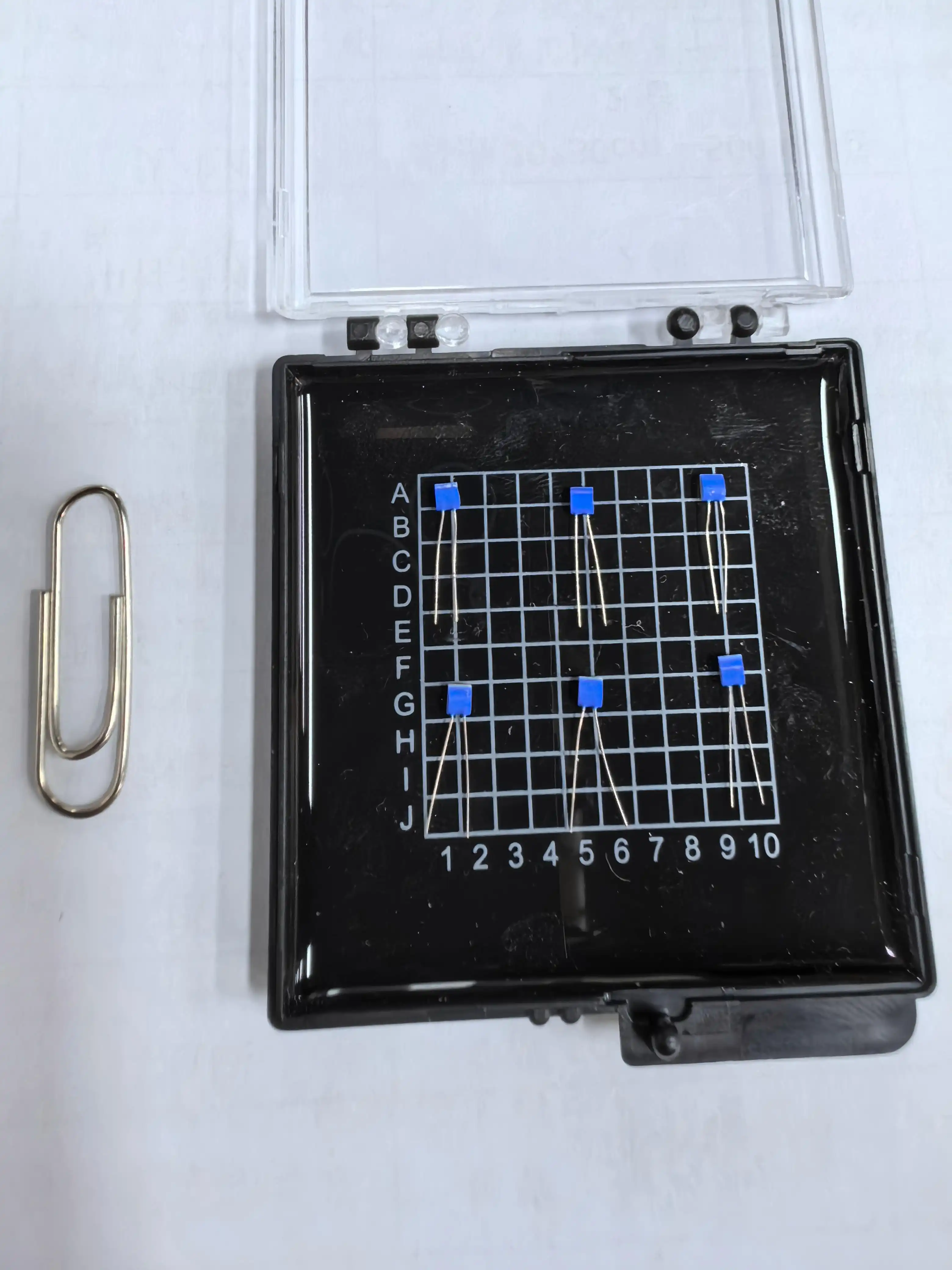

Pt300 Thin Film Sensor

Element Dimensions:2.0mm x 3.0mm x 1.0mm

Lead Specifications:Length: 10 mm,Diameter: 0.2 mm

Lead Material: Platinum-nickel wire (optional: silver-palladium/platinum/pure silver)

Lead Tensile Strength:≥9 N

Insulation Resistance:100 MΩ at 20°C, >2 MΩ at 500°C

Temperature Coefficient (TCR):3850 ppm/°C

Operating Current:0.1–0.8 mA (self-heating effect to be considered)

Long-Term Stability:≤±0.04% resistance drift of R₀ (0°C reference) after 1000 hours at 500°C

Response Time:Water Flow (V=0.4 m/s):₀.₅ = 0.05 s,t₀.₉ = 0.15 s;Airflow (V=2 m/s):t₀.₅ = 3 s,t₀.₉ = 10 s

Self-Heating Coefficient:0.4°C/mW (at 0°C)

Vibration Resistance:≥40g acceleration (frequency range: 10–2000 Hz)

Shock Resistance:≥100g acceleration (8 ms half-sine wave)

Packaging:Vacuum plastic packaging (other packaging formats available upon request)

Pt300 Thin Film Sensor Manufacturer And Supplier

As a leading Pt300 Thin Film Sensor manufacturer and supplier, Xi'an Tongzida Technology combines advanced thin-film chip design, IEC60751 compliance, and 15+ years of expertise. Our sensors deliver unmatched accuracy (±0.01Ω), stability (≤0.04% drift), and durability (100g shock resistance), empowering industries like aerospace, automotive, and medical tech to thrive in extreme environments.

Why Choose Our Pt300 Thin Film Sensor?

- Global Certifications: ISO9001, CE, RoHS, and IEC60751 compliance.

- Custom Solutions: Tailored lead materials, sizes, and packaging.

- Rigorous Testing: Automated production with 100% quality checks.

- Fast Response: As quick as 0.05 seconds in liquid environments.

Pt300 Thin Film Sensor Specifications

| Parameter | Value |

|---|---|

| Dimensions | 2.0mm x 3.0mm x 1.0mm |

| Lead Material Options | Platinum-nickel, silver-palladium, pure platinum |

| Temperature Range | -200°C to +850°C |

| TCR (Temperature Coefficient) | 3850 ppm/°C |

| Insulation Resistance | 100 MΩ at 20°C; >2 MΩ at 500°C |

| Vibration Resistance | 40g (10–2000 Hz) |

| Shock Resistance | 100g (8 ms half-sine wave) |

Reference Selection Guide

| Application | Recommended Configuration |

|---|---|

| Automotive Engine Monitoring | Platinum leads, vacuum packaging, 3.0mm size |

| Medical Lab Equipment | Pure silver leads, 1.2mm size, 0.1 mA operating current |

| Aerospace Systems | Platinum-nickel leads, 4.0mm size, 0.8 mA current |

Key Features of Our Pt300 Thin Film Sensor

- Ultra-Wide Temperature Range: Reliable performance from cryogenic (-200°C) to high-heat (+850°C) environments.

- Minimal Self-Heating: 0.4°C/mW coefficient ensures accurate readings without interference.

- Long-Term Stability: ≤±0.04% resistance drift after 1000 hours at 500°C.

- Robust Construction: Withstands harsh vibrations, shocks, and rapid thermal cycling.

Where Is the Pt300 Thin Film Sensor Used?

- Industrial: Process control, machinery health monitoring.

- Medical: Diagnostic tools, wearable health devices.

- Automotive: EV battery thermal management, engine sensors.

- Aerospace: Avionics, fuel system monitoring.

Certificates & Compliance

Our Pt300 Thin Film Sensors are meticulously engineered to meet the rigorous requirements of ISO9001, RoHS, and CE standards. The ISO9001 certification validates our commitment to maintaining a robust quality management system throughout the production process, ensuring consistent and reliable performance. RoHS compliance underscores our dedication to using environmentally friendly materials, minimizing the impact on the planet. The CE mark attests to our adherence to strict European health, safety, and environmental protection regulations. For customers in the automotive industry, we offer the option of obtaining automotive-grade certifications upon request. These additional certifications guarantee that our sensors meet the specific, demanding criteria of automotive applications, providing enhanced reliability and safety for vehicles and related systems.

Packing & Delivery

Our standard vacuum plastic packaging serves as a reliable safeguard for our products, creating an airtight environment that effectively shields them from external factors such as dust, moisture, and physical damage during transit. This packaging method not only preserves the integrity of the items but also extends their shelf life. Recognizing that different needs may arise, we also support custom packaging solutions, including anti-static and moisture-proof options, tailored to specific requirements. Whether it's protecting sensitive electronic components from electrostatic discharge or preventing humidity-related issues, our custom packaging ensures maximum product safety. To facilitate global distribution, we partner with renowned carriers DHL and FedEx, ensuring prompt and secure delivery to customers worldwide.

FAQs: Pt300 Thin Film Sensor

- What's the lead time for bulk orders?

Typical lead time: 2–4 weeks. Expedited options available. - Can I request non-standard lead lengths?

Yes! We customize lead lengths from 5mm to 50mm. - Are your sensors compatible with legacy systems?

Absolutely. Share your specs, and we'll adapt our design. - Do you offer technical support post-purchase?

Free integration guides and 24/7 engineering support included. - Is bulk pricing negotiable?

Yes. Contact us for volume discounts and annual contracts.

Contact Us for Your Pt300 Thin Film Sensor Needs!

Ready to enhance your systems with Pt300 Thin Film Sensors? Email sales11@xatzd.com for quotes, samples, or technical queries.

Learn about our latest products and discounts through SMS or email