- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

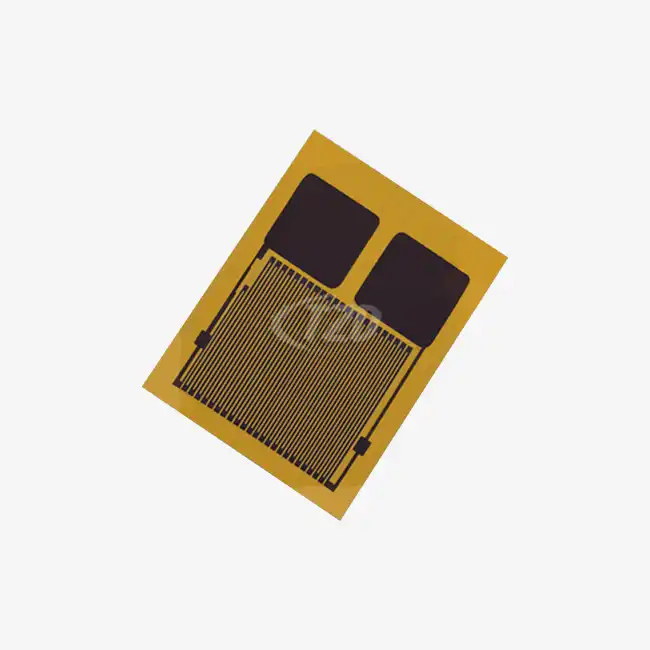

Flexible Thermal Sensing Film For Medical

Temperature Measurement Grade:Class A (±0.6°C),Class B (±1.2°C)

Pad Material:Tinned

Temperature Range:-70°C to +200°C

Base Resistance:Ω (Value to be specified)

Temperature Coefficient (TCR):6444 ppm/°C

Flexible Thermal Sensing Film For Medical Manufacturer And Supplier

Xi'an Tongzida Technology Co., Ltd. is a trusted Flexible Thermal Sensing Film For Medical manufacturer and supplier. With advanced thin-film sensor technology and ISO 13485, CE, and RoHS certifications, we deliver precision, durability, and compliance for medical wearables, diagnostic tools, and telehealth solutions.

Introduction to Flexible Thermal Sensing Film For Medical Devices

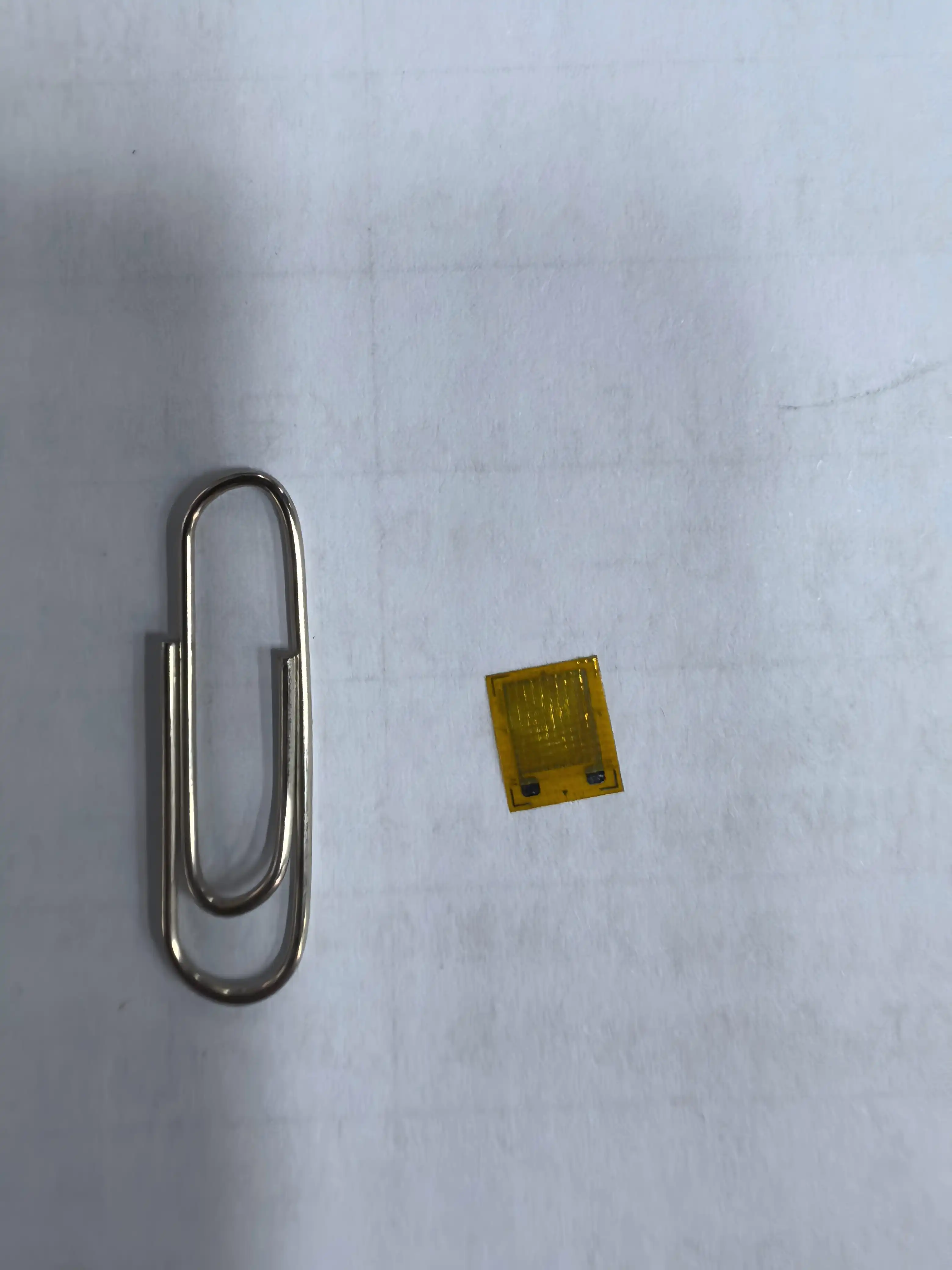

Precision meets flexibility with our product applications. Designed for seamless integration into wearable health monitors, smart bandages, and surgical tools, our ultra-thin (0.05mm) film ensures accurate temperature monitoring (±0.6°C) across -70°C to +200°C. Trusted by leading medtech innovators, our sensors combine biocompatibility (ISO 10993) with unmatched durability for long-term patient care.

Why Choose Our Medical-Grade Thermal Sensors?

- Medical Compliance: Our products are pre-certified for FDA, CE, and RoHS standards, assuring strict adherence to the highest medical safety and environmental protection requirements across the globe.

- Customization: We offer extensive customization options. With a default size of 7mm x 5mm, you can adjust dimensions, TCR (6444 ppm/°C), and choose from lead materials like tinned pads or platinum to fit specific needs.

- Rapid Response: Boasting an impressive 0.05-second reaction time, our products enable real-time diagnostics, providing immediate and accurate data crucial for efficient medical decision-making.

- Scalability: Leveraging automated production processes, we guarantee consistent quality across bulk orders, ensuring that every product meets our stringent standards regardless of quantity.

- Technical Support: Our team provides comprehensive assistance, including prototyping help and regulatory guidance, to support you through every stage of product development and compliance.

Specifications

| Parameter | Details |

|---|---|

| Dimensions | 7mm x 5mm x 0.05mm (Customizable) |

| Temperature Accuracy | Class A (±0.6°C), Class B (±1.2°C) |

| Temperature Range | -70°C to +200°C |

| Base Resistance | Custom Ω values available |

| TCR (Temperature Coefficient) | 6444 ppm/°C |

| Lead Material | Tinned, Platinum Nickel, or Pure Pt |

Features of Our Flexible Thermal Sensing Film

- Body-Friendly Design: Stretchable, lightweight, and sterilizable (autoclave-safe).

- High Stability: Drift ≤0.04% over 1,000+ hours.

- Vibration Resistance: Withstands 40g vibration and 100g shock.

- Vacuum-Compatible: Ideal for surgical or lab environments.

Applications in Medical Technology

- Wearable Health Monitors: Continuous temperature patches for remote patient care.

- Smart Bandages: Infection detection in wound healing.

- Diagnostic Tools: Disposable sensors for clinics.

- Surgical Equipment: Real-time thermal mapping during procedures.

Certifications

Our Flexible Thermal Sensing Film For Medical solutions is a testament to our unwavering commitment to quality and safety. Rigorously engineered, these films meet the stringent ISO 13485 standard, which is dedicated to quality management systems for medical devices, ensuring that every aspect of production adheres to the highest healthcare industry benchmarks. Additionally, our compliance with RoHS regulations underscores our dedication to environmental responsibility by limiting the use of hazardous substances, safeguarding both patients and the planet. Our adherence to REACH standards further demonstrates our commitment to proper chemical management, ensuring transparency and traceability. Together, these certifications make our Flexible Thermal Sensing Film a reliable, safe, and eco - friendly choice for advanced medical applications.

Packing and Delivery

Our products are safeguarded with utmost care using vacuum-sealed, ESD (Electrostatic Discharge)-safe packaging. The vacuum-sealing process creates an airtight environment that effectively protects against moisture, dust, and oxidation, ensuring the integrity of the contents during transit and storage. The ESD-safe feature provides an additional layer of protection, preventing sensitive electronic components from potential damage caused by electrostatic discharge. Complemented by our extensive global logistics support, we ensure seamless delivery across the world. Leveraging reliable carriers and efficient supply chain management, we can handle shipments to any destination, making sure your products reach you in perfect condition, regardless of geographical location.

FAQ

Q: Is the film biocompatible for skin contact?

A: Yes! It's ISO 10993-tested for prolonged wear.

Q: Can I order prototypes before bulk production?

A: Absolutely—we offer free samples for testing.

Q: What's the lead time for 10,000+ units?

A: 2–3 weeks with expedited options.

Q: Do you provide custom TCR values?

A: Yes, we adjust TCR to match your device's needs.

Q: Are technical documents available?

A: Full datasheets and compliance reports provided.

Empower Your Medical Innovations Today!

Ready to integrate high-precision Flexible Thermal Sensing Film For Medical devices? Contact our team at sales11@xatzd.com for quotes, samples, or technical consultations.

Learn about our latest products and discounts through SMS or email