The Remarkable Characteristics of Thin Film Pt100 Sensors

Precision and Stability in Temperature Measurement

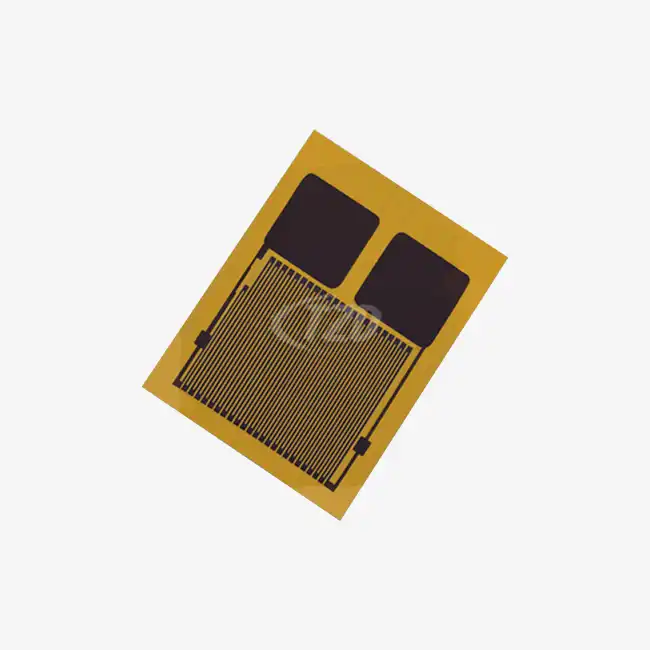

Thin Film Pt100 Sensors are marvels of modern temperature sensing technology. These sensors utilize a thin layer of platinum deposited on a ceramic substrate, resulting in a compact and highly responsive device. The platinum's purity and the precise deposition process contribute to the sensor's exceptional accuracy, typically within ±0.01 Ω at 0°C. This level of precision is crucial for applications where even minor temperature fluctuations can have significant consequences.

One of the standout features of Thin Film Pt100 Sensors is their remarkable long-term stability. With a drift of ≤±0.04% in resistance after 1000 hours at 500°C, these sensors maintain their accuracy over extended periods, even in harsh environments. This stability is particularly valuable in industrial processes where consistent, reliable measurements are essential for quality control and safety.

Rapid Response and Miniaturization

The thin film construction of these sensors confers several advantages, chief among them being their rapid response time. In flowing conditions (V=0.4 m/s), these sensors can achieve a t0.5 response time of just 0.05 seconds and a t10 of 0.15 seconds. This quick reaction to temperature changes makes them ideal for dynamic systems where real-time monitoring is crucial.

Moreover, the miniaturization capabilities of thin film technology allow for sensors with dimensions as small as 1.2mm x 2.0mm x 1.0mm. This compact size enables integration into tight spaces and small devices, opening up new possibilities for temperature measurement in previously inaccessible locations. The reduced thermal mass of these miniature sensors also contributes to their faster response times.

Durability and Environmental Resistance

Thin Film Pt100 Sensors are built to withstand challenging conditions. With a vibration resistance of ≥40g acceleration across a frequency range of 10 to 2000 Hz, these sensors can operate reliably in environments with significant mechanical stress. Their shock resistance is equally impressive, capable of withstanding ≥100g acceleration in an 8 ms half-sine wave.

The sensors' leads, typically made of platinum-nickel wire with a tensile strength of ≥9 N, provide robust connectivity. Alternative lead materials such as silver-palladium, pure platinum, or silver-nickel are available to suit specific application requirements. This flexibility in lead material selection enhances the sensor's adaptability to various industrial environments.

Applications Across Industries: Leveraging the Wide Temperature Range

Industrial Process Control and Monitoring

The wide temperature range of Thin Film Pt100 Sensors makes them indispensable in numerous industrial applications. In steel manufacturing, these sensors can monitor temperatures from the initial melting stages to the final heat treatment processes. Their ability to withstand high temperatures and maintain accuracy over time is crucial in ensuring consistent product quality and process efficiency.

In the chemical industry, Thin Film Pt100 Sensors play a vital role in reaction vessel temperature control. The sensors' fast response time allows for precise regulation of exothermic and endothermic reactions, ensuring safety and optimal yield. Their resistance to corrosive environments further enhances their suitability for chemical processing applications.

Aerospace and Aviation

The aerospace industry relies heavily on Thin Film Pt100 Sensors for their wide temperature range and robust construction. These sensors are used in aircraft engines to monitor combustion temperatures, ensuring optimal performance and fuel efficiency. In space applications, they're employed to measure temperatures in satellite systems, where reliability under extreme conditions is paramount.

The sensors' ability to operate at cryogenic temperatures also makes them valuable in liquid fuel systems for rockets and spacecraft. Their compact size and resistance to vibration and shock make them ideal for integration into avionics systems, where space is at a premium and environmental stresses are significant.

Medical and Laboratory Equipment

In the medical field, Thin Film Pt100 Sensors find applications in a variety of equipment. They're used in sterilization autoclaves, where precise temperature control is essential for effective disinfection. In medical freezers and cryogenic storage units, these sensors provide accurate monitoring of ultra-low temperatures, crucial for preserving biological samples and pharmaceuticals.

Research laboratories utilize Thin Film Pt100 Sensors in analytical instruments such as gas chromatographs and spectrophotometers. The sensors' high accuracy and stability ensure reliable results in sensitive scientific experiments. Their miniature size also allows for integration into microfluidic devices and lab-on-a-chip systems, enabling precise temperature control in miniaturized analytical platforms.

Pushing the Boundaries: Innovations in Thin Film Pt100 Sensor Technology

Enhanced Performance Through Material Science

Recent advancements in material science have led to improvements in Thin Film Pt100 Sensor performance. Researchers are exploring novel substrate materials and platinum alloys to extend the temperature range even further while maintaining or improving accuracy. These innovations aim to push the upper temperature limit beyond 850°C, opening up new possibilities in high-temperature applications such as jet engine monitoring and advanced materials processing.

Developments in nanostructured platinum films promise to enhance sensor sensitivity and reduce response times even further. By manipulating the platinum film at the nanoscale, scientists are creating sensors with increased surface area and improved thermal coupling, resulting in faster and more precise temperature measurements.

Integration with Smart Technologies

The future of Thin Film Pt100 Sensors lies in their integration with smart technologies. Manufacturers are developing sensors with built-in signal processing capabilities, allowing for direct digital output and easier integration with industrial control systems. This advancement reduces signal noise and simplifies installation, making these sensors more accessible for a wider range of applications.

Internet of Things (IoT) connectivity is another frontier for Thin Film Pt100 Sensors. By incorporating wireless communication modules, these sensors can transmit real-time temperature data to cloud-based platforms, enabling remote monitoring and predictive maintenance. This connectivity is particularly valuable in large-scale industrial operations and distributed sensing networks.

Customization and Application-Specific Design

As the demand for specialized temperature sensing solutions grows, manufacturers are offering increasingly customized Thin Film Pt100 Sensors. This includes tailored packaging solutions to protect sensors in particularly harsh environments, such as corrosive chemical processes or high-radiation areas. Custom lead configurations and mounting options are being developed to facilitate integration into complex systems and tight spaces.

Application-specific calibration and characterization services are becoming more common, ensuring that sensors meet the exact requirements of particular industries or processes. This level of customization allows users to optimize sensor performance for their specific needs, improving overall system efficiency and reliability.

Conclusion

Thin Film Pt100 Sensors continue to evolve, pushing the boundaries of temperature measurement technology. Their wide temperature range, coupled with ongoing innovations, ensures their relevance in an ever-expanding array of applications. As industries demand more precise, reliable, and versatile temperature sensing solutions, these sensors are poised to meet the challenge. For more information on cutting-edge Thin Film Pt100 Sensors and how they can benefit your specific application, please contact us at sales11@xatzd.com.