- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

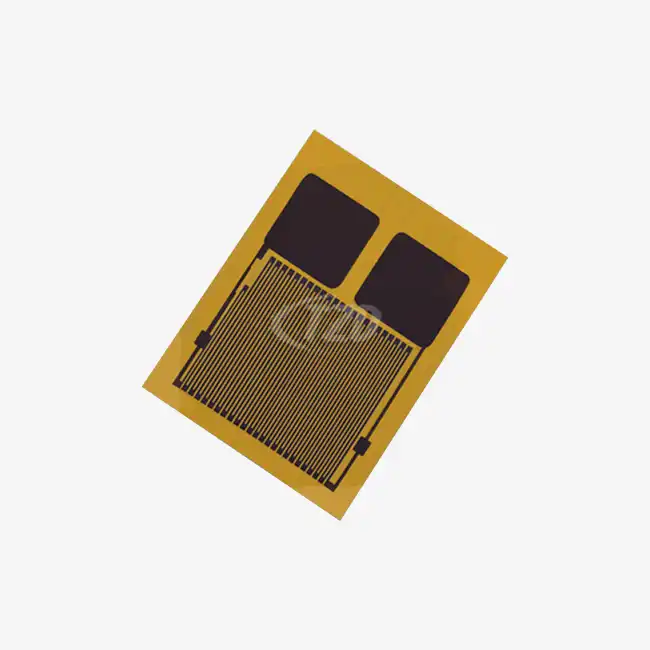

IC Manufacturing Temperature Sensor

Element Dimensions:2.0mm x 3.0mm x 1.0mm

Lead Specifications:Length: 10 mm,Diameter: 0.2 mm

Lead Material: Platinum-nickel wire (optional: silver-palladium/platinum/pure silver)

Lead Tensile Strength:≥9 N

Insulation Resistance:100 MΩ at 20°C, >2 MΩ at 500°C

Temperature Coefficient (TCR):3850 ppm/°C

Operating Current:0.1–0.8 mA (self-heating effect to be considered)

Long-Term Stability:≤±0.04% resistance drift of R₀ (0°C reference) after 1000 hours at 500°C

Response Time:Water Flow (V=0.4 m/s):₀.₅ = 0.05 s,t₀.₉ = 0.15 s;Airflow (V=2 m/s):t₀.₅ = 3 s,t₀.₉ = 10 s

Self-Heating Coefficient:0.4°C/mW (at 0°C)

Vibration Resistance:≥40g acceleration (frequency range: 10–2000 Hz)

Shock Resistance:≥100g acceleration (8 ms half-sine wave)

Packaging:Vacuum plastic packaging (other packaging formats available upon request)

IC Manufacturing Temperature Sensor: Precision for Semiconductor Production

Xi'an Tongzida Technology Co., Ltd. is a leading manufacturer and supplier of IC Manufacturing Temperature Sensors. Our progressed sensors offer unparalleled exactness, soundness, and unwavering quality for semiconductor creation forms. With our cutting-edge innovation and commitment to quality, we give inventive arrangements that meet the demanding requests of the semiconductor industry.

Introduction

In the fast-paced world of semiconductor fabricating, exact temperature control is pivotal for guaranteeing item quality and optimizing generation yields. Our item is planned to meet the rigid prerequisites of present day fabs and bundling offices. With industry-leading execution and unwavering quality, our sensors engage producers to accomplish more tightly handle control and progress in general effectiveness.

Why Choose Us?

- Expertise in Semiconductor Applications: Our team of engineers understands the unique challenges of IC manufacturing environments.

- Customization Capabilities: We offer tailored solutions to meet your specific process requirements.

- Proven Reliability: Our sensors undergo rigorous testing to ensure long-term stability and accuracy.

- Comprehensive Support: From pre-sales engineering assistance to post-installation troubleshooting, we're committed to your success.

- Supply Chain Resilience: With our robust production capabilities, we ensure consistent availability and on-time delivery.

Specifications

| Parameter | Value |

|---|---|

| Element Type | Thin Film Platinum Resistance Thermistor |

| Element Dimensions | 2.0mm x 3.0mm x 1.0mm |

| Lead Specifications | Length: 10 mm, Diameter: 0.2 mm |

| Lead Material | Platinum-nickel wire (customizable) |

| Temperature Coefficient | 3850 ppm/°C |

| Operating Current | 0.1–0.8 mA |

| Long-Term Stability | ≤±0.04% resistance drift after 1000 hrs at 500°C |

| Insulation Resistance | 100 MΩ at 20°C, >2 MΩ at 500°C |

| Vibration Resistance | ≥40g acceleration (10–2000 Hz) |

| Shock Resistance | ≥100g acceleration (8 ms half-sine wave) |

Reference Selection

| Temperature Range (°C) | Recommended Model |

|---|---|

| -200 to 0 | TZD-ICT-L |

| 0 to 300 | TZD-ICT-M |

| 300 to 850 | TZD-ICT-H |

Features

- High Accuracy: ±0.1°C or better across a wide temperature range

- Rapid Response: t₀.₅ = 0.05 s in water flow (V=0.4 m/s)

- Excellent Stability: Minimal drift over time, even in extreme conditions

- EMI Resistance: Designed to withstand electromagnetic interference in complex fab environments

- Flexible Integration: Compact size and customizable leads for easy incorporation into existing systems

Applications

Our IC Manufacturing Temperature Sensor is ideal for various critical applications in semiconductor production:

- Wafer Processing: Precise temperature monitoring during deposition, etching, and lithography

- Thermal Management: Ensuring optimal operating conditions for sensitive equipment

- Process Control: Real-time feedback for temperature-dependent fabrication steps

- Quality Assurance: Monitoring thermal uniformity in test and packaging processes

- R&D and Failure Analysis: Accurate temperature data for process optimization and troubleshooting

By incorporating our advanced product into your production line, you can achieve tighter process control, enhance product quality, and ultimately improve your competitive edge in the semiconductor market. Our sensors are designed to meet the evolving needs of the industry, supporting the development of next-generation chips and advanced packaging technologies.

Certificates

We maintain rigorous quality standards, holding ISO 9001, ROHS, and CE certifications.

Packing and Delivery

Our sensors are vacuum-sealed for protection, with customized packaging options available.

FAQ

Q1: What is the typical lead time for custom orders?

A1: Lead times vary based on specifications, but we typically deliver within 4-6 weeks for custom orders.

Q2: Do you offer calibration services?

A2: Yes, we provide NIST-traceable calibration for all our products.

Q3: Can these sensors be used in cleanroom environments?

A3: Absolutely. Our sensors are designed and packaged to meet cleanroom compatibility requirements.

Q4: What is your minimum order quantity (MOQ)?

A4: Our standard MOQ is 1000 units, but we can accommodate smaller quantities for specialized applications.

Q5: Do you offer technical support for integration?

A5: Yes, our engineering team provides comprehensive support from initial design to final implementation.

Contact Us

For inquiries or to discuss your specific IC Manufacturing Temperature Sensor needs, please contact our sales team at sales11@xatzd.com. We're ready to help you optimize your semiconductor manufacturing processes with our cutting-edge temperature sensing solutions.

Learn about our latest products and discounts through SMS or email