- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

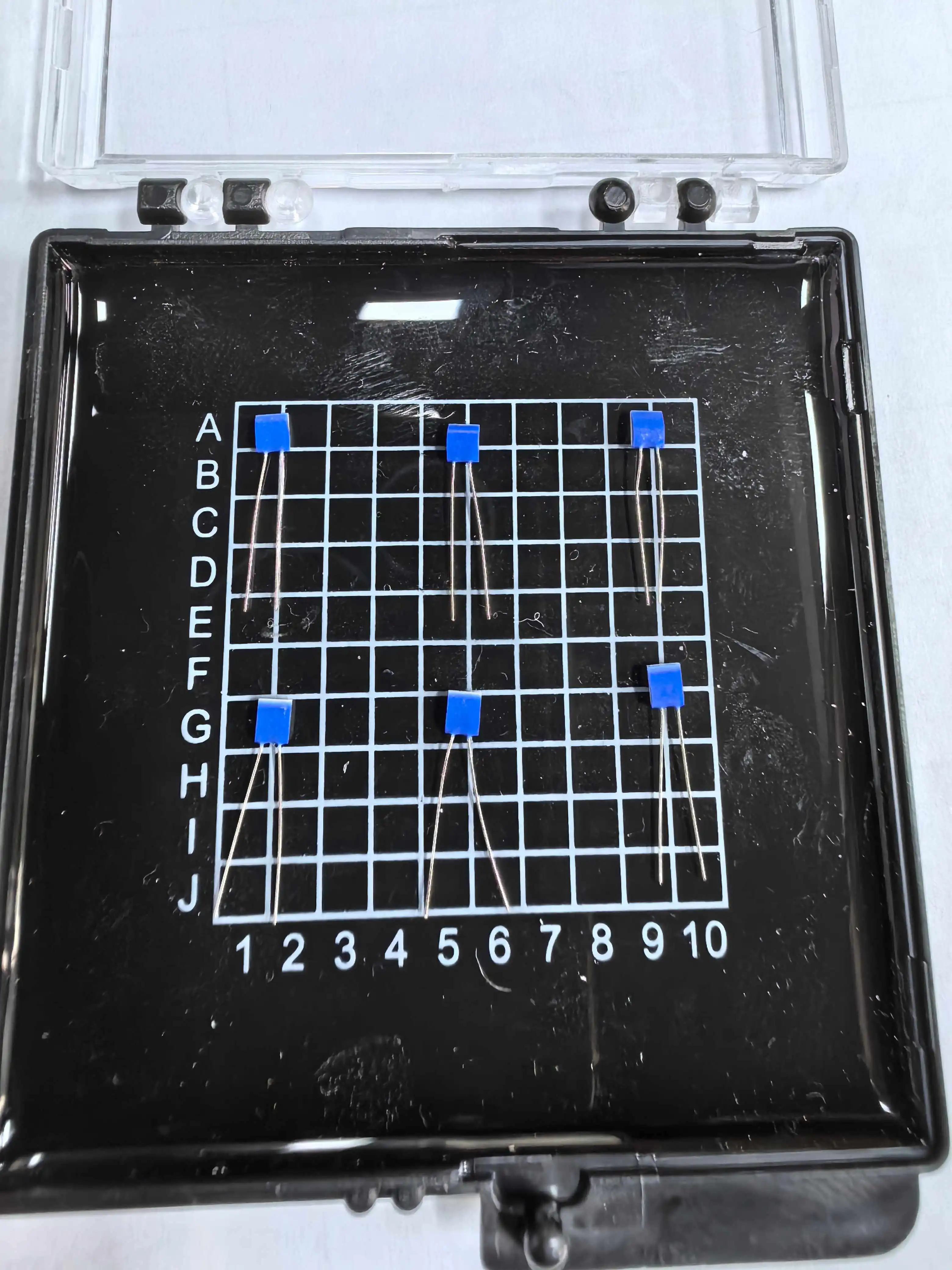

Wafer Lithography Temperature Sensor

Element Dimensions:2.0mm x 2.3mm x 1.0mm,1.6mm x 2.0mm x 1.0mm,1.2mm x 2.0mm x 1.0mm

Lead Specifications:Length: 10 mm,Diameter: 0.2 mm

Lead Material: Platinum-nickel wire (optional: silver-palladium/platinum/silver-nickel)

Lead Tensile Strength:≥9 N

Insulation Resistance:100 MΩ at 20°C, >2 MΩ at 500°C

Temperature Coefficient (TCR):3850 ppm/°C

Operating Current:0.3 ~ 1 mA (self-heating effect to be considered)

Long-Term Stability:≤±0.04% resistance drift after 1000 hours at 50°C

Response Time:[Flow (V=0.4 m/s)]t0.5 = 0.05 s,t10 = 0.15 s[Airflow (V=2 m/s)]t0.5 = 3 s,t10 = 10 s

Self-Heating Coefficient:0.4°C/mW

Vibration Resistance:≥40g acceleration (10 ~ 2000 Hz frequency range)

Shock Resistance:≥100g acceleration (8 ms half-sine wave)

Packaging:Vacuum plastic packaging (other packaging formats available upon request)

Wafer Lithography Temperature Sensor: Precision Control for Advanced Semiconductor Manufacturing

Xi'an Tongzida Technology Co., Ltd. is a leading manufacturer and supplier of Wafer Lithography Temperature Sensors. Our progressed sensors offer unparalleled accuracy, unwavering quality, and strength for the most requesting semiconductor fabricating forms. With our cutting-edge thin-film platinum resistance innovation, we provide temperature estimation arrangements that meet the demanding guidelines of the world's beat foundries, IDMs, and OEMs.

Introduction

In the high-stakes world of semiconductor fabrication, precision is everything. Our products are designed to provide the ultra-accurate temperature control essential for modern lithography processes. These sensors are the cornerstone of maintaining process stability, ensuring consistent quality, and maximizing yield in advanced chip production.

Why Choose Us?

- Industry-Leading Precision: Our sensors offer sub-millidegree accuracy, crucial for nanometer-scale lithography.

- Proven Reliability: With long-term stability drift of ≤0.04%, our sensors ensure consistent performance over time.

- Customization Capabilities: We offer tailored solutions to meet your specific integration and performance requirements.

- Global Compliance: Our products meet international standards and regulations, including ISO9001, RoHS, and CE certifications.

- Comprehensive Support: From technical consultation to post-sale calibration, we're committed to your success.

Specifications

| Parameter | Value |

|---|---|

| Element Type | Thin Film Platinum Resistance Thermistor |

| Element Dimensions | 2.0mm x 2.3mm x 1.0mm, 1.6mm x 2.0mm x 1.0mm, 1.2mm x 2.0mm x 1.0mm |

| Lead Specifications | Length: 10 mm, Diameter: 0.2 mm |

| Lead Material | Platinum-nickel wire (optional: silver-palladium/platinum/silver-nickel) |

| Temperature Coefficient (TCR) | 3850 ppm/°C |

| Operating Current | 0.3 ~ 1 mA |

| Long-Term Stability | ≤±0.04% resistance drift after 1000 hours at 50°C |

| Response Time | [Flow (V=0.4 m/s)] t0.5 = 0.05 s, t10 = 0.15 s |

| Vibration Resistance | ≥40g acceleration (10 ~ 2000 Hz frequency range) |

| Shock Resistance | ≥100g acceleration (8 ms half-sine wave) |

Features

- Ultra-high precision for critical lithography processes

- Exceptional stability for long-term reliability

- Rapid response time for real-time temperature control

- Robust design for harsh semiconductor manufacturing environments

- Versatile lead options for seamless integration

- Vacuum-compatible for advanced lithography systems

Applications

Our Wafer Lithography Temperature Sensors excel in:

- Advanced semiconductor fabrication

- Photolithography process control

- Wafer inspection and metrology

- Thermal management in high-precision manufacturing

- Research and development of next-generation chip technologies

Certificates

We maintain rigorous quality standards, evidenced by our ISO9001, RoHS, and CE certifications.

Packing and Delivery

Our sensors are vacuum-sealed to ensure pristine condition upon arrival, with customizable packaging options available.

FAQ

Q: How do your sensors ensure accuracy in lithography processes?

A: Our sensors provide sub-millidegree accuracy through advanced thin-film technology and precise calibration.

Q: Can these sensors integrate with existing lithography equipment?

A: Yes, we offer customization options to ensure compatibility with your current systems.

Q: What is the typical lead time for bulk orders?

A: We typically fulfill large orders within 4-6 weeks, depending on specifications and quantity.

Q: How do you support customers after purchase?

A: We offer comprehensive technical support, including calibration services and troubleshooting assistance.

Q: Are your sensors suitable for extreme temperature environments?

A: Our sensors perform reliably across a wide range, from -200°C to +850°C, meeting diverse application needs.

Contact Us

For inquiries about our Wafer Lithography Temperature Sensors or to discuss your specific requirements, please contact our sales team at sales11@xatzd.com. Our experts are ready to help you achieve precision temperature control in your semiconductor manufacturing processes.

Learn about our latest products and discounts through SMS or email