- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

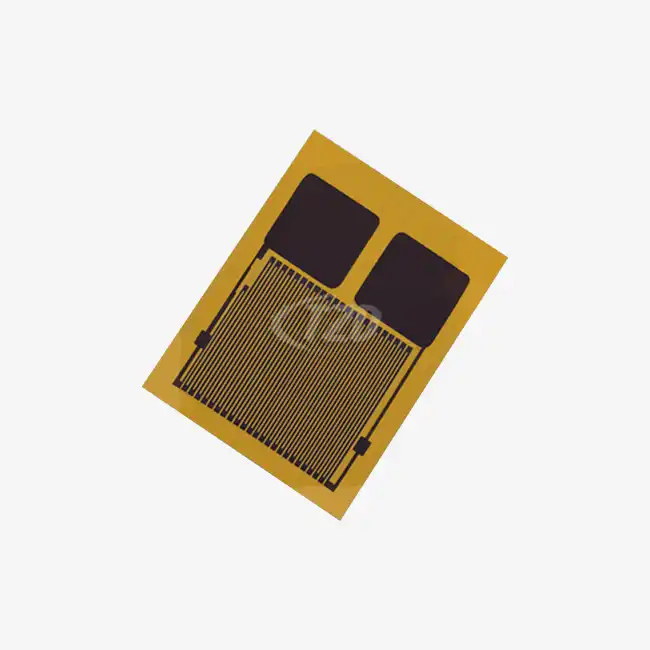

High temperature sensor

Element Dimensions:2.0mm x 2.3mm x 1.0mm,1.6mm x 2.0mm x 1.0m,1.2mm x 2.0mm x 1.0mm

Lead Specifications:Length: 10 mm,Diameter: 0.2 mm

Lead Material: Platinum-nickel wire (optional: silver-palladium/platinum/silver-nickel)

Lead Tensile Strength:≥9 N

Insulation Resistance:100 MΩ at 20°C, >2 MΩ at 500°C

Temperature Coefficient (TCR):3850 ppm/°C

Operating Current:0.3 ~ 1 mA (self-heating effect to be considered)

Long-Term Stability:≤±0.04% resistance drift after 1000 hours at 50°C

Response Time:Flow (V=0.4 m/s):t0.5 = 0.05 s,t10 = 0.15 s;Airflow (V=2 m/s):t0.5 = 3 s,t10 = 10 s

Self-Heating Coefficient:0.4°C/mW

Vibration Resistance:≥40g acceleration (10 ~ 2000 Hz frequency range)

Shock Resistance:≥100g acceleration (8 ms half-sine wave)

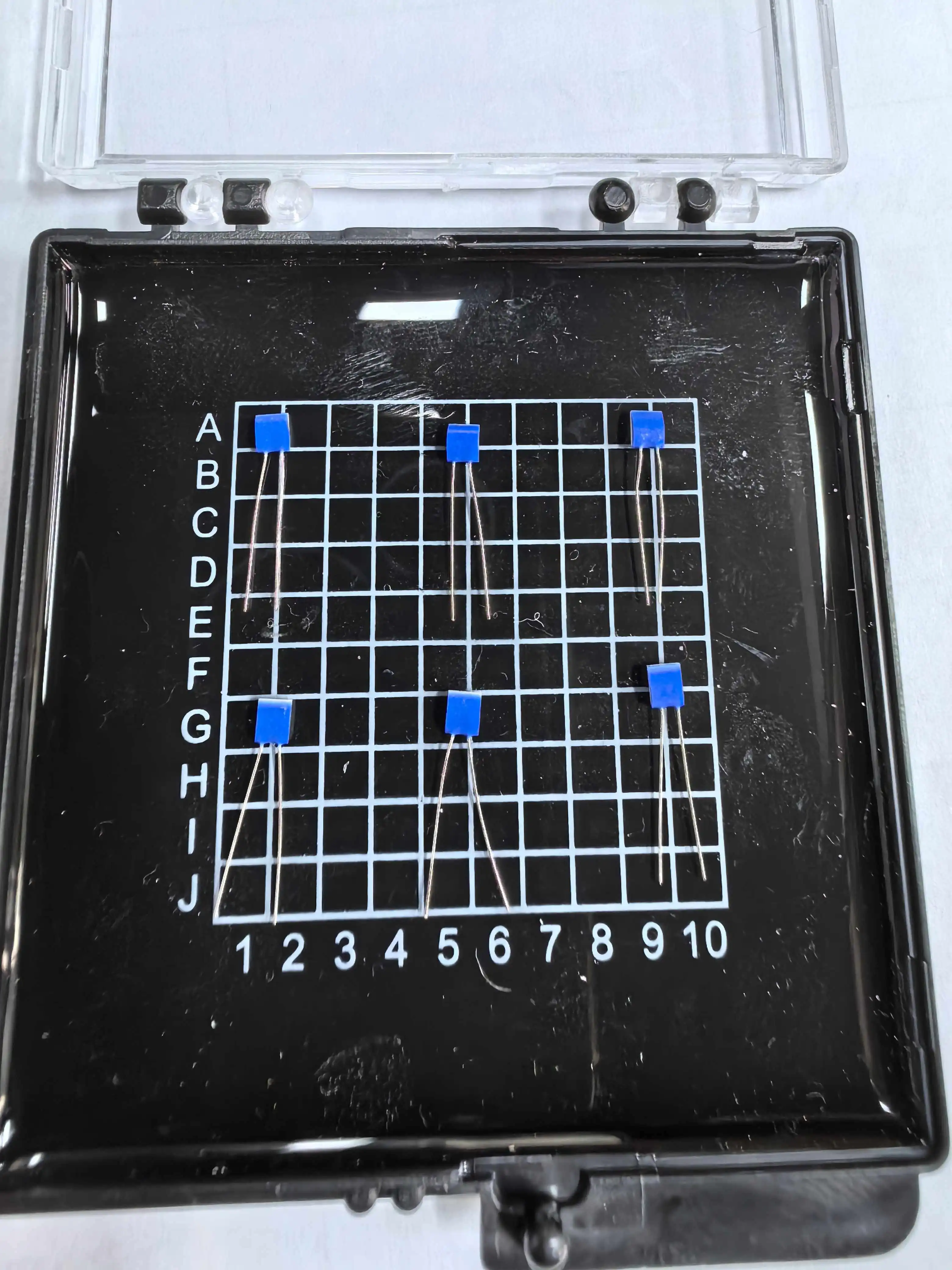

Packaging:Vacuum plastic packaging (other packaging formats available upon request)

High Temperature Sensor Manufacturer And Supplier

At Xi'an Tongzida Technology Co., Ltd., we specialize in designing high temperature sensors that thrive in the toughest industrial conditions. With 20+ years of expertise in thin-film platinum resistance technology, our sensors deliver unmatched accuracy (±0.01Ω), stability (±0.04% drift), and durability (up to 850°C). ISO 9001, CE, and RoHS-certified, we empower industries like aerospace, energy, and automotive to achieve reliable temperature monitoring with cutting-edge solutions.

Why Choose Our High Temperature Sensor?

- 3850 ppm/°C TCR: Industry-leading temperature coefficient ensures precision.

- Wide Range: Operate seamlessly from -200°C to +850°C.

- Robust Build: Withstand 40g vibration, 100g shock, and harsh chemical exposure.

- Fast Response: Reach 0.05s in flow conditions for real-time monitoring.

- Customizable: Tailor sizes (1.2mm–4.0mm), lead materials (Pt-Ni/Ag-Pd), and packaging.

Specifications

| Parameter | Details |

|---|---|

| Element Dimensions | 2.0mm x 2.3mm x 1.0mm, 1.6mm x 2.0mm x 1.0mm, 1.2mm x 2.0mm x 1.0mm |

| Lead Material | Platinum-Nickel (Default), Silver-Palladium, Pure Platinum |

| Temperature Range | -200°C to +850°C |

| Accuracy | ±0.01Ω (1/40B Level) |

| Response Time (Flow) | t0.5 = 0.05s; t10 = 0.15s |

| Insulation Resistance | 100 MΩ at 20°C; >2 MΩ at 500°C |

| Certifications | ISO 9001, CE, RoHS |

Reference Selection Guide

| Application | Recommended Model | Key Benefit |

|---|---|---|

| Automotive Testing | TZ-HT-2.0 (Pt-Ni Leads) | Shock-resistant, fast response |

| Power Plant Monitoring | TZ-HT-1.6 (Ag-Pd Leads) | High insulation at 500°C+ |

| Aerospace R&D | TZ-HT-1.2 (Pure Pt Leads) | Ultra-compact, vacuum-compatible |

Features Built for Demanding Environments

- Military-Grade Durability: Survive 100g shocks and extreme thermal cycling.

- Self-Heating Mitigation: 0.4°C/mW coefficient minimizes measurement errors.

- Long-Term Stability: ≤0.04% drift after 1,000 hours at 50°C.

- Easy Integration: Compatible with PLCs, SCADA, and legacy systems.

Where Our High Temperature Sensors Excel

- Industrial: Furnace control, turbine monitoring, molten metal processing.

- Energy: Boiler safety, geothermal systems, oil refinery pipelines.

- Healthcare: Sterilization autoclaves, lab equipment calibration.

- Aerospace: Jet engine testing, satellite thermal management.

Certificates & Compliance

All of our high temperature sensors are meticulously crafted to meet the stringent requirements of the IEC 60751 standards, a globally recognized benchmark for temperature sensor accuracy and reliability. But our commitment to quality doesn't stop there. Each sensor then undergoes an extensive and rigorous in - house testing regime. This comprehensive evaluation includes multiple rounds of performance checks, durability tests, and functionality assessments. By subjecting our sensors to such thorough scrutiny, we ensure that every product leaving our facility offers consistent, precise performance, providing our customers with the confidence that our sensors will excel in even the most demanding applications.

Packing & Delivery

Every product is securely encased in vacuum-sealed anti-static packaging, providing a dual-layered defense mechanism. The vacuum-sealing creates an airtight barrier, effectively protecting the contents from moisture, dust, and oxidation. Simultaneously, the anti-static properties safeguard sensitive components from electrostatic discharge, ensuring their integrity during transit. For bulk orders, we prioritize efficiency without compromising on quality. Leveraging our streamlined logistics processes and robust supply chain, we guarantee dispatch within 5–7 days. This rapid turnaround time, combined with our reliable packaging, ensures that your large-scale orders reach you promptly and in pristine condition.

FAQs

Q1: Can you customize sensors for unique temperature ranges?

Yes! We adjust materials and coatings for -270°C to +1000°C.

Q2: What's the lead time for 10,000+ units?

Standard orders ship in 7 days; large volumes require 2–3 weeks.

Q3: Do your sensors comply with ATEX/IECEx?

We provide Ex-certified versions for hazardous zones.

Q4: How do I reduce self-heating effects?

Our team offers free wiring and calibration guides.

Q5: Is there a minimum order quantity (MOQ)?

MOQ is 100 units, with samples available for testing.

Contact Us for Precision You Can Trust

Need a high temperature sensor that outperforms in extreme conditions? Our engineers are ready to help!

📧 Email: sales11@xatzd.com

🌐 Custom Quotes Delivered in 24 Hours

Learn about our latest products and discounts through SMS or email