- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

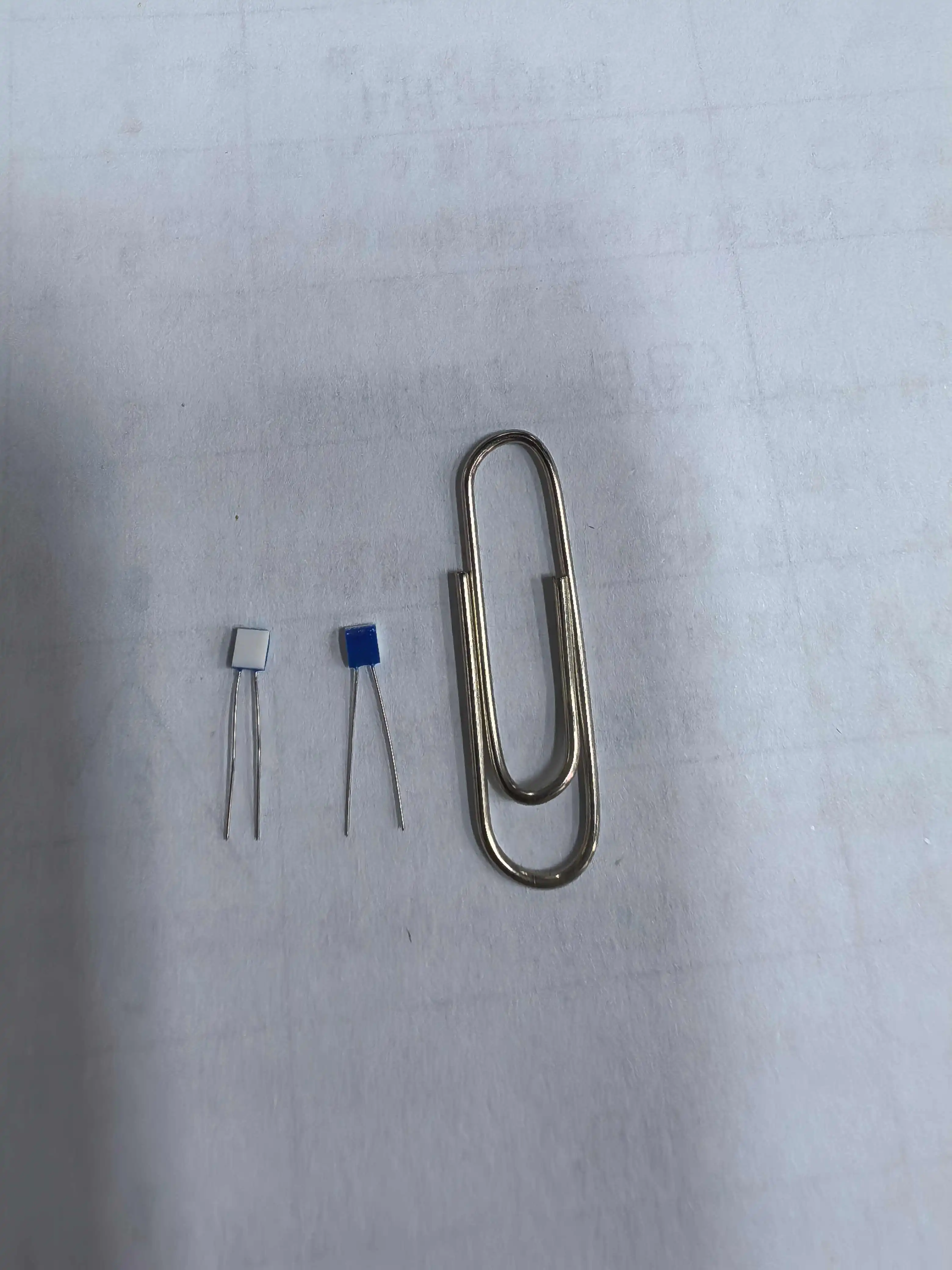

Screw Type Thermal Resistance Temperature Sensor

Temperature Ranges:0°C to +150°C;-50°C to +300°C;-70°C to +300°C

Wire Configuration:Two-wire system;Three-wire system;Four-wire system

Lead Wire Materials:FEP (Fluorinated Ethylene Propylene);Silicone Rubber;PTFE (Polytetrafluoroethylene);PVC (Polyvinyl Chloride)

Metal Braided High-Temperature Wire

Temperature Coefficient:TK = 3850 ppm/K

Self-Heating Coefficient:0.4 K/mW (at 0°C)

Accuracy Classes:1/3B Class: Tolerance ≤ ±0.10°C (0°C to +150°C)

A Class: Tolerance ≤ ±0.15°C (-50°C to +300°C)

B Class: Tolerance ≤ ±0.30°C (-70°C to +300°C)

Operating Current:100Ω: 0.3~1 mA

500Ω: 0.1~0.7 mA

1000Ω: 0.1~0.3 mA

Insulation Resistance:≥100 MΩ @ 500 V DC & 20°C

Pressure Resistance Standard:≥0.5 MPa

Screw Type Thermal Resistance Temperature Sensor Manufacturer And Supplier

At Xi'an Tongzida Technology Co., Ltd., we specialize in manufacturing high-performance Screw Type Thermal Resistance Temperature Sensors (RTDs) designed for industrial, medical, and aerospace applications. With ISO9001, CE, and RoHS certifications, our sensors deliver unmatched accuracy (±0.01Ω), stability (≤0.04% drift), and durability in extreme conditions (-200°C to +850°C).

Why Choose Our Screw Type Thermal Resistance Temperature Sensor?

- Advanced RTD Technology: Built with Pt100/Pt500/Pt1000 elements for precise temperature measurement.

- Wide Compatibility: Supports 2/3/4-wire configurations and FEP/PTFE/PVC lead materials.

- Robust Design: Resists vibration (40g), shock (100g), and pressure (≥0.5 MPa).

- Custom Solutions: Tailored thread sizes, wire lengths, and output signals to fit your system.

Key Specifications

| Parameter | Details |

|---|---|

| RTD Types | Pt100, Pt500, Pt1000 |

| Temperature Range | -70°C to +300°C (B Class), -50°C to +300°C (A Class), 0°C to +150°C (1/3B) |

| Accuracy | ±0.10°C (1/3B), ±0.15°C (A), ±0.30°C (B) |

| Wire Configuration | 2-wire, 3-wire, 4-wire |

| Lead Materials | FEP, Silicone, PTFE, PVC, Metal Braided |

| Response Time | ≤0.05 seconds |

| Insulation Resistance | ≥100 MΩ @ 500V DC |

Reference Selection Guide

| Industry | Recommended Model | Key Feature |

|---|---|---|

| Industrial Manufacturing | PT100-3W-FEP | High vibration resistance, 4-20mA output |

| HVAC Systems | PT1000-4W-PTFE | Wide range (-70°C to +300°C), low self-heat |

| Automotive | PT500-MetalBraided | Shockproof, 0.05s response time |

| Pharmaceuticals | PT100-2W-Silicone | Hygienic design, ±0.1°C accuracy |

Features That Set Us Apart

- Ultra-Fast Response: Monitor temperature changes in real time (0.05s) for critical processes.

- Long-Term Stability: Minimal drift ensures consistent performance over years.

- Versatile Installation: Screw-type design adapts to pipes, tanks, or machinery.

- Harsh Environment Ready: Operate flawlessly in corrosive, high-pressure, or humid settings.

Where Our Sensors Excel

- Steel Plants: Monitor furnace temps with Pt1000 sensors (0°C to +850°C).

- Pharma Labs: Ensure sterile conditions with FDA-grade PTFE leads.

- Renewable Energy: Track geothermal or solar thermal systems reliably.

- Automotive Testing: Measure exhaust temps with shock-resistant models.

Certifications & Quality Assurance

All of our Screw Type Thermal Resistance Temperature Sensors are meticulously designed and manufactured to meet the exacting requirements of IEC60751 standards, ensuring their reliability and accuracy in various applications. To further guarantee their quality, each sensor undergoes a series of rigorous tests. Insulation testing verifies the electrical isolation properties, preventing leakage and ensuring safety. Pressure testing simulates different environmental pressures to ensure the sensors can withstand real-world conditions without failure. Thermal cycling tests subject the sensors to extreme temperature fluctuations, assessing their ability to maintain performance across a wide range of temperatures. This comprehensive testing process ensures that our sensors deliver consistent, high - quality performance.

Packaging & Delivery

Our products are carefully processed to ensure maximum protection during transit. Each unit is vacuum - sealed, creating an airtight environment that shields against moisture, dust, and oxidation, preserving the integrity of the contents. These vacuum - sealed units are then placed in anti - static packaging, which safeguards sensitive components from electrostatic discharge, preventing potential damage. For bulk orders, we prioritize efficiency and prompt delivery. Understanding the importance of timely receipt, we guarantee that all bulk orders will be dispatched within 7 days. This rapid turnaround time ensures that you can meet your project deadlines and keep your operations running smoothly.

FAQs

- What's the lead time for custom sensors?

→ 2-3 weeks for tailored specs; standard models ship in 5 days. - Can I request a non-standard thread size?

→ Yes! We offer M6 to M12 threads for seamless integration. - Do your sensors comply with ATEX directives?

→ Absolutely—ask our team about explosion-proof variants. - How do I reduce self-heating errors?

→ Use 4-wire configurations for minimal current interference. - Do you provide calibration certificates?

→ Each sensor includes a traceable ISO17025 certificate.

Contact us

Email sales11@xatzd.com for quotes, technical drawings, or sample requests. Let's build a solution that matches your Screw Type Thermal Resistance Temperature Sensors needs!

Learn about our latest products and discounts through SMS or email