- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

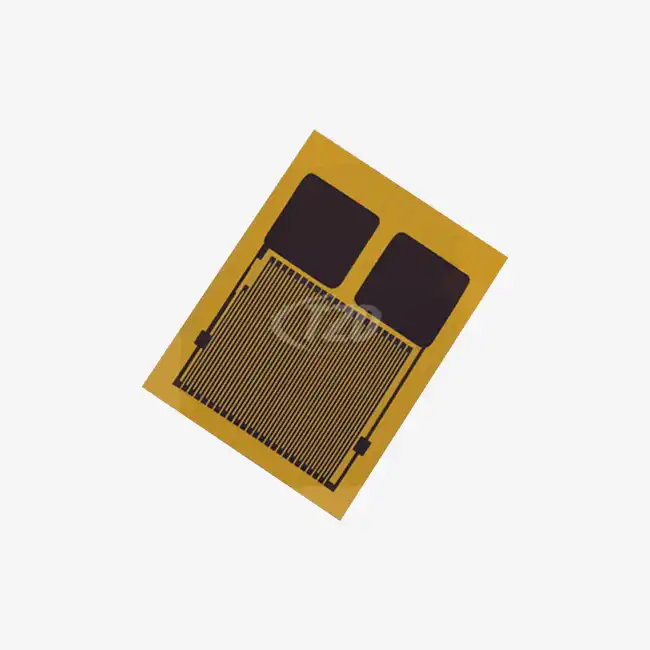

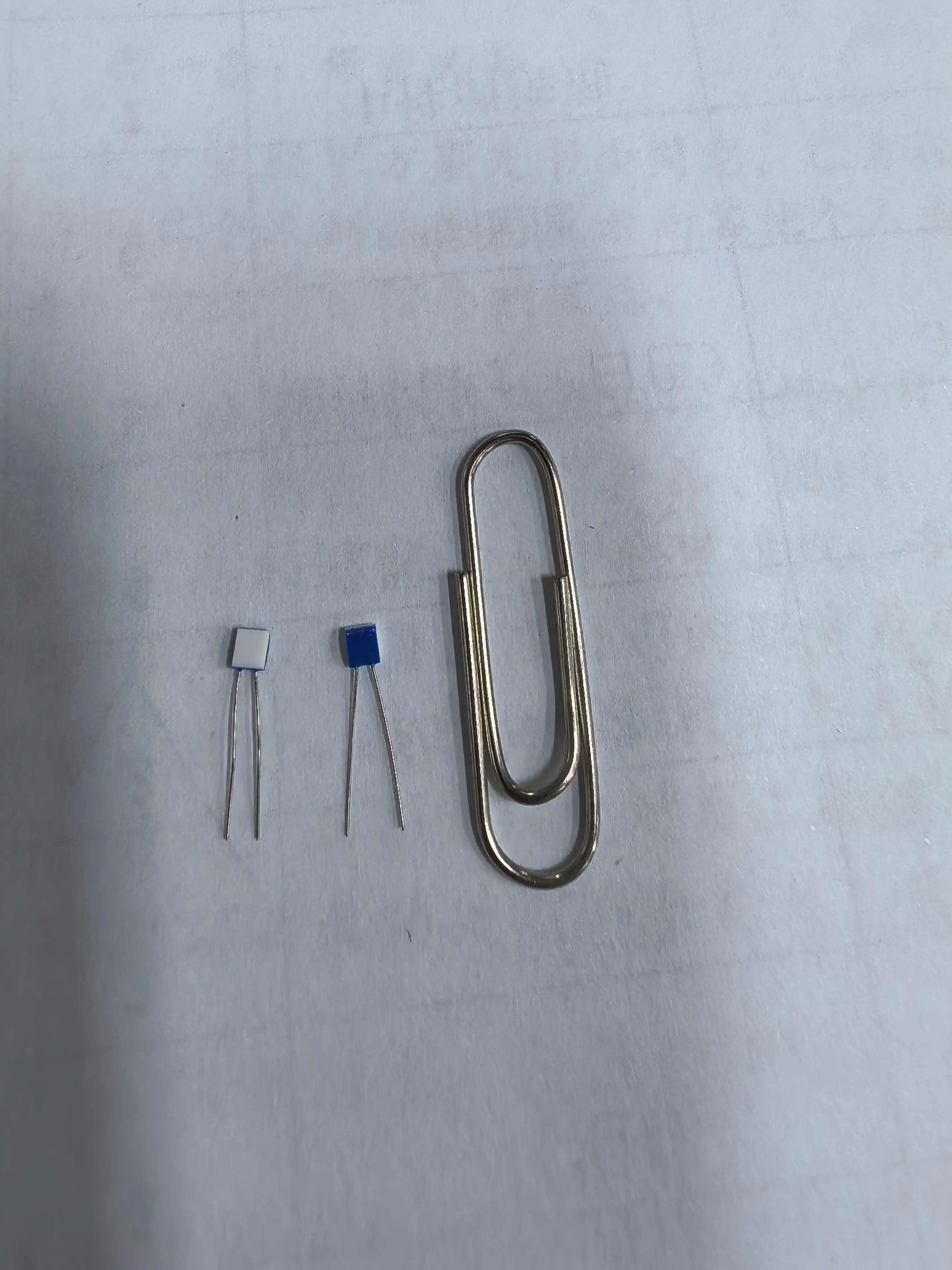

Pt1000 RTD Element

Element Dimensions:2.0mm x 2.3mm x 1.0mm,2.0mm x 4.0mm x 1.0mm

Lead Specifications:Length: 10 mm,Diameter: 0.2 mm

Lead Material: Platinum-nickel wire (optional: silver-palladium/platinum/pure silver)

Lead Tensile Strength:≥9 N

Insulation Resistance:100 MΩ at 20°C, >2 MΩ at 500°C

Temperature Coefficient (TCR):3850 ppm/°C

Operating Current:0.1–0.3 mA (self-heating effect to be considered)

Long-Term Stability:≤±0.04% resistance drift of R₀ (0°C reference) after 1000 hours at 500°C

Response Time:Water Flow (V=0.4 m/s):t₀.₅ = 0.05 s,t₀.₉ = 0.15 s;Airflow (V=2 m/s):t₀.₅ = 3 s,t₀.₉ = 10 s

Self-Heating Coefficient:0.4°C/mW (at 0°C)

Vibration Resistance:≥40g acceleration (frequency range: 10–2000 Hz)

Shock Resistance:≥100g acceleration (8 ms half-sine wave)

Packaging:Vacuum plastic packaging (other packaging formats available upon request)

Precision Pt1000 RTD Element Manufacturer & Supplier

As a leading innovator in sensor technology, Xi'an Tongzida specializes in high-performance Pt1000 RTD Elements designed for extreme accuracy and durability. Our ISO 9001, CE, and RoHS-certified solutions combine advanced thin-film platinum technology with customizable designs to meet global industrial demands.

Why Choose Our Pt1000 RTD Elements?

Engineered for reliability, our platinum resistance thermometers deliver:

- Wide Temperature Range: -200°C to +850°C, ideal for harsh environments.

- Ultra-Fast Response: Detect changes in 0.05 seconds (liquid flow).

- Long-Term Stability: ≤0.04% drift after 1,000 hours at 50°C.

- Robust Build: Withstand 40g vibration and 100g shock for aerospace/automotive use.

- Flexible Customization: Tailor lead materials, sizes, and packaging to your needs.

Pt1000 RTD Element Specifications

| Parameter | Value |

|---|---|

| Dimensions | 2.0mm x 2.3mm x 1.0mm, 2.0mm x 4.0mm x 1.0mm |

| Lead Material | Platinum-nickel (default), silver-palladium, pure platinum |

| Temperature Coefficient | 3850 ppm/°C (IEC 60751 compliant) |

| Insulation Resistance | 100 MΩ at 20°C, >2 MΩ at 500°C |

| Response Time (Airflow) | t₀.₅ = 3 s, t₀.₉ = 10 s |

| Self-Heating Coefficient | 0.4°C/mW at 0°C |

Reference Selection Guide

| Application | Recommended Configuration |

|---|---|

| EV Battery Thermal Management | 2.0mm x 4.0mm, platinum leads, vacuum packaging |

| Medical Sterilization Systems | 2.0mm x 2.3mm, silver-palladium leads, Class A accuracy |

| Industrial Process Control | Custom sheath materials, 100g shock resistance |

Key Features of Our Platinum RTD Sensors

- Precision Engineering: Achieve ±0.01Ω accuracy for critical measurements.

- Multi-Industry Compatibility: Optimized for HVAC, aerospace, and renewable energy systems.

- Low Self-Heating: Minimize measurement errors with 0.4°C/mW efficiency.

- Scalable Solutions: Bulk orders supported with competitive pricing and MOQ flexibility.

Where Are Pt1000 RTD Elements Used?

Our temperature sensors excel in:

- Industrial Automation: Monitor reactors, turbines, and pipelines.

- Medical Devices: Ensure safety in MRI machines and sterilization units.

- Renewable Energy: Optimize solar thermal and geothermal systems.

- Aerospace: Track engine temperatures with vibration-resistant designs.

Certifications & Quality Assurance

Every single Pt1000 RTD Element in our inventory undergoes an exhaustive and meticulous testing process, strictly adhering to the high - standards set by both ISO 9001 and ASTM E1137. The ISO 9001 certification ensures that our quality management system is robust and reliable, while ASTM E1137 guarantees accurate and consistent temperature - resistance measurements. To provide our customers with complete transparency and peace of mind, we offer full material traceability, allowing you to track the origin and composition of each element. Additionally, we provide comprehensive calibration certificates, validating the precision and reliability of our products, ensuring they meet the most demanding application requirements.

Packaging & Delivery

Our standard vacuum-sealed plastic packaging is the ultimate safeguard for your products during transit. By creating an airtight environment, it effectively blocks out dust, moisture, and other contaminants, ensuring that each item reaches its destination in pristine condition. Recognizing the critical timelines often associated with OEM projects, we offer expedited shipping services. Whether you're facing tight production schedules or unexpected demand surges, our express shipping options are designed to prioritize and fast-track your urgent orders, ensuring that you receive the products you need precisely when you need them.

Frequently Asked Questions

Q1: Can you customize lead lengths beyond 10mm?

Yes! We adjust lead configurations to match your device's PCB or connector layout.

Q2: Are your sensors compatible with ATEX zones?

Absolutely. We offer intrinsically safe designs for hazardous environments.

Q3: What's the typical lead time for 5,000 units?

Standard orders ship in 2–3 weeks. Rush production available for 25% fee.

Q4: Do you provide technical drawings for integration?

Detailed CAD files and wiring diagrams come with every bulk order.

Q5: How do you ensure batch-to-batch consistency?

Our automated production line guarantees ≤0.02% variance in TCR values.

Empower Your Systems with Precision

Need a Pt1000 RTD Element that outperforms in stability and speed? Contact our engineering team at sales11@xatzd.com for samples or custom quotes. Let's build sensors that scale with your ambitions!

Learn about our latest products and discounts through SMS or email