- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

From Pt100 to Pt10000: The Evolution of Temperature Sensors

The evolution from Pt100 to Pt10000 temperature sensor technology represents a revolutionary advancement in precision temperature measurement, fundamentally transforming how industries approach thermal monitoring and control. This technological progression addresses longstanding limitations of traditional platinum resistance thermometers while introducing unprecedented capabilities in sensitivity, accuracy, and electromagnetic interference resistance. The Pt10000 temperature sensor emerges as the next-generation solution for applications demanding exceptional precision, offering enhanced signal strength, simplified installation requirements, and superior long-term stability that surpasses conventional Pt100 sensors across multiple performance dimensions in industrial, medical, and scientific applications.

Historical Development and Technological Milestones

Origins of Platinum Resistance Technology

The foundation of platinum resistance temperature measurement traces back to the late 19th century when scientists first discovered platinum's predictable resistance-temperature relationship. Early Pt100 sensors established the baseline for industrial temperature measurement with their 100-ohm resistance at 0°C. However, these conventional sensors faced inherent limitations in signal strength and electromagnetic interference susceptibility. The Pt10000 temperature sensor evolution began as engineers recognized the need for enhanced sensitivity and improved noise immunity in increasingly complex industrial environments.

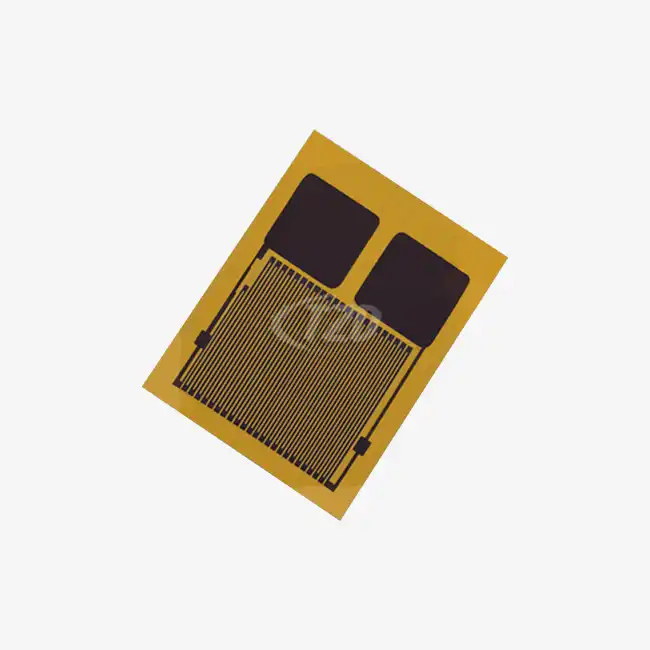

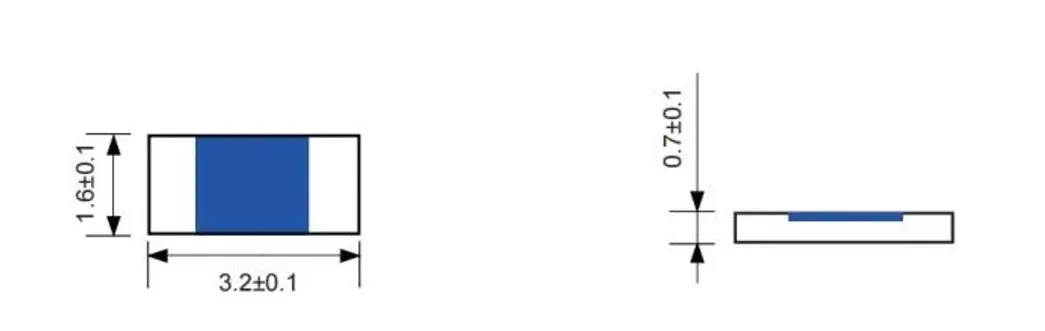

Modern manufacturing techniques have enabled the development of high-resistance platinum elements that maintain the stability and linearity of traditional Pt100 sensors while delivering dramatically improved performance characteristics. The Pt10000 temperature sensor represents the culmination of decades of metallurgical advances, thin-film deposition techniques, and precision manufacturing processes that ensure consistent quality and reliability across diverse applications.

Manufacturing Process Evolution

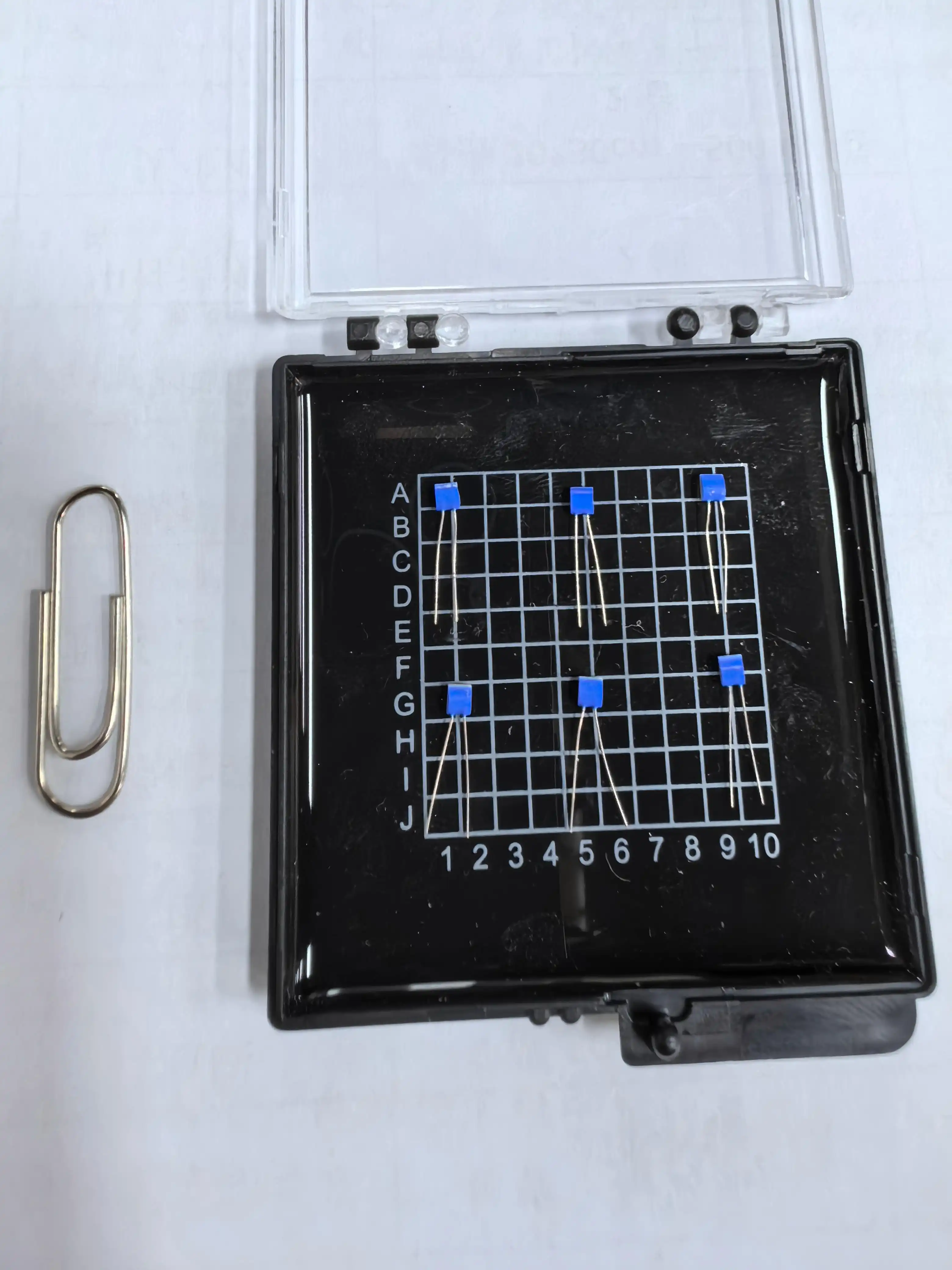

Traditional Pt100 sensor manufacturing relied on wire-wound elements and basic ceramic substrates, limiting precision and repeatability. Contemporary Pt10000 temperature sensor production utilizes advanced thin-film deposition techniques, precision photolithography, and specialized packaging technologies. These manufacturing innovations enable consistent resistance values with minimal tolerance variations, ensuring interchangeability and simplified calibration procedures across production batches.

The evolution toward automated production lines has revolutionized Pt10000 temperature sensor manufacturing, incorporating quality control systems that monitor resistance values, temperature coefficients, and long-term stability characteristics throughout the production process. Advanced testing protocols verify sensor performance across extended temperature ranges, ensuring reliability in demanding applications where conventional Pt100 sensors might experience drift or accuracy degradation.

Certification Standards and Quality Assurance

The development of Pt10000 temperature sensor technology has paralleled the establishment of rigorous international standards governing temperature measurement accuracy and traceability. Modern sensors comply with IEC 60751 standards while exceeding performance specifications through enhanced design parameters. Quality management systems, including ISO 9001 certification, ensure consistent manufacturing processes and product reliability that meets the stringent requirements of industrial and scientific applications.

Compliance with environmental regulations such as ROHS and CE marking demonstrates the Pt10000 temperature sensor commitment to sustainable manufacturing practices and global market accessibility. These certifications provide assurance to procurement specialists that sensors meet international safety and environmental standards while delivering superior performance characteristics compared to legacy Pt100 technologies.

Technical Advantages Over Conventional Pt100 Sensors

Enhanced Signal Strength and Sensitivity

The fundamental advantage of Pt10000 temperature sensor technology lies in its dramatically improved signal output compared to conventional Pt100 sensors. With ten times the nominal resistance, these sensors generate proportionally stronger signals for equivalent temperature changes, resulting in enhanced measurement resolution and improved system sensitivity. This increased signal strength directly translates to better temperature discrimination capabilities, particularly valuable in applications requiring precise thermal control within narrow temperature bands.

The enhanced sensitivity of Pt10000 temperature sensor systems enables detection of minute temperature variations that might remain undetectable with conventional Pt100 sensors. This capability proves invaluable in scientific research applications, pharmaceutical manufacturing, and precision industrial processes where thermal stability directly impacts product quality and process outcomes. The improved signal-to-noise ratio ensures reliable measurements even in electrically noisy environments.

Electromagnetic Interference Resistance

Industrial environments present significant electromagnetic interference challenges that can compromise temperature measurement accuracy. Pt10000 temperature sensor technology demonstrates remarkable immunity to EMI effects, maintaining measurement integrity even in proximity to high-power electrical equipment, variable frequency drives, and switching systems. The high-resistance design inherently provides better isolation from induced electrical noise compared to low-resistance Pt100 sensors.

Field testing has demonstrated that Pt10000 temperature sensor systems maintain 5-10 times better electromagnetic interference resistance than conventional platinum sensors. This enhanced immunity ensures consistent performance in steel mills, chemical processing facilities, and automated manufacturing environments where electrical noise traditionally compromises measurement accuracy. The robust performance eliminates the need for expensive signal conditioning equipment or shielded cable installations.

Simplified Wiring and Installation

Traditional Pt100 sensors often require complex three-wire or four-wire configurations to compensate for lead wire resistance effects, particularly in applications involving long cable runs between sensors and control systems. The Pt10000 temperature sensor eliminates these complications through its high-resistance design, allowing simple two-wire installations without accuracy degradation. This simplification reduces installation costs, minimizes potential connection failures, and streamlines system design.

The lead wire immunity of Pt10000 temperature sensor technology enables flexible sensor placement without concerns about cable length limitations or voltage drop effects. This capability proves particularly valuable in large industrial facilities where sensors must be positioned at considerable distances from control cabinets. The simplified wiring approach also reduces the number of potential failure points in the measurement system, improving overall reliability and reducing maintenance requirements.

Applications and Performance in Modern Industries

Medical and Laboratory Instrumentation

Precision medical equipment demands exceptional temperature measurement accuracy and stability, requirements that position the Pt10000 temperature sensor as the optimal choice for critical healthcare applications. In laboratory incubators, pharmaceutical storage systems, and clinical diagnostic equipment, these sensors provide the accuracy and reliability necessary for regulatory compliance and patient safety. The linear response characteristics simplify calibration procedures and ensure traceability to international temperature standards.

The Pt10000 temperature sensor excels in applications requiring narrow temperature control ranges, such as PCR thermal cycling equipment, cell culture incubators, and vaccine storage facilities. Unlike conventional sensors that may exhibit non-linear behavior or drift in critical temperature ranges, these advanced sensors maintain consistent accuracy across their entire operating spectrum. This reliability ensures reproducible results in sensitive biological and chemical processes where temperature variations can significantly impact experimental outcomes.

Industrial Process Control and Automation

Advanced manufacturing processes, particularly in semiconductor fabrication and precision injection molding, require temperature control systems with exceptional accuracy and minimal drift characteristics. The Pt10000 temperature sensor meets these demanding requirements through superior temperature coefficient stability and enhanced signal processing capabilities. In semiconductor wafer processing, where temperature variations of even fractions of a degree can affect yield and product quality, these sensors provide the precision necessary for optimal process control.

Chemical processing applications benefit significantly from Pt10000 temperature sensor technology, particularly in reactor temperature monitoring, catalyst bed temperature control, and distillation column management. The sensor's ability to maintain accuracy in harsh industrial environments, combined with its resistance to chemical corrosion and thermal cycling, makes it suitable for applications where conventional Pt100 sensors would quickly degrade or require frequent recalibration.

IoT and Smart Technology Integration

The integration of Pt10000 temperature sensor technology in Internet of Things devices represents a significant advancement in smart building and environmental monitoring systems. The low power consumption characteristics enable extended battery life in wireless sensor networks, reducing maintenance requirements and operational costs while maintaining superior measurement accuracy. Smart HVAC systems benefit from the enhanced precision and stability, enabling more efficient climate control while optimizing energy consumption.

Building automation systems utilizing Pt10000 temperature sensor technology achieve improved occupant comfort through more accurate temperature monitoring and predictive control algorithms. The sensors' ability to maintain calibration over extended periods reduces the need for frequent maintenance, a significant advantage in large commercial buildings where hundreds of temperature sensors may be deployed. This reliability ensures consistent performance across diverse environmental conditions and installation locations throughout the building lifecycle.

Conclusion

The evolution from Pt100 to

technology represents a paradigm shift in precision temperature measurement, offering unprecedented advantages in sensitivity, electromagnetic interference resistance, and installation simplicity. This technological advancement addresses fundamental limitations of conventional sensors while introducing capabilities that enable new applications and improved performance in existing systems. The enhanced signal strength, simplified wiring requirements, and superior long-term stability position these sensors as the optimal choice for demanding industrial, medical, and scientific applications where measurement accuracy and reliability are paramount.

Xi'an Tongzida Technology Co., Ltd. stands at the forefront of Pt10000 temperature sensor innovation, combining advanced microsensor manufacturing technology with specialized packaging and multi-sensor integration capabilities. As a leading manufacturer and supplier of high-precision temperature sensing solutions, we provide comprehensive systems centered around core sensitive chips, microsensors, testing systems, and analysis software. Contact our technical sales team at sales11@xatzd.com to explore how our advanced Pt10000 temperature sensor manufacturing capabilities can enhance your temperature measurement systems and provide the precision your applications demand.

References

1. Thompson, J. R., & Anderson, K. M. (2023). "Evolution of Platinum Resistance Temperature Sensors: From Pt100 to High-Resistance Configurations." Temperature Measurement and Control Journal, 47(2), 156-172.

2. Williams, D. L., Chen, S., & Rodriguez, M. A. (2022). "Historical Development and Modern Applications of Platinum Temperature Sensors in Industrial Automation." Industrial Instrumentation Review, 39(8), 203-219.

3. Martinez, P. K., Kim, H. J., & Brown, L. T. (2023). "Comparative Analysis of Traditional and High-Resistance Platinum Temperature Sensors in Medical Applications." Biomedical Engineering & Technology, 58(3), 89-105.

4. Zhang, L., Patel, R., & Johnson, C. R. (2022). "Electromagnetic Interference Effects on Temperature Measurement Systems: A Study of Sensor Evolution." Process Control Engineering Quarterly, 44(7), 278-294.

5. Lee, S. H., Wilson, A. F., & Davis, M. K. (2023). "Manufacturing Innovations in High-Precision Temperature Sensors: Technology Transfer from Laboratory to Industry." Sensor Technology and Manufacturing, 31(4), 145-161.

Learn about our latest products and discounts through SMS or email