- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How to Troubleshoot Temperature Sensor Errors Quickly?

Rapid troubleshooting of temperature sensor errors requires systematic diagnostic approaches that identify common failure modes and implement effective corrective actions to minimize system downtime. Professional maintenance teams must understand the fundamental principles underlying temperature sensor operation, common error patterns, and proven diagnostic procedures that enable quick fault isolation and resolution. Modern industrial processes depend heavily on accurate temperature measurements for quality control, safety systems, and process optimization, making rapid error diagnosis critical for operational continuity. The temperature sensor serves as a vital component in measurement systems, and understanding its failure mechanisms enables maintenance personnel to implement targeted troubleshooting strategies that restore system functionality efficiently.

Common Temperature Sensor Error Types and Identification Methods

Electrical Connection and Wiring Issues

Temperature sensor wiring problems represent the most frequent source of measurement errors, often manifesting as intermittent readings, complete signal loss, or erratic behavior that correlates with mechanical vibration or environmental conditions. Loose connections, corroded terminals, and damaged insulation create resistance changes that appear as temperature variations in the measurement system. Professional troubleshooting procedures begin with systematic inspection of all electrical connections, terminal conditions, and wire integrity throughout the signal path from sensor to measurement equipment.

Advanced diagnostic techniques include resistance measurements across connection points, insulation testing between conductors and ground, and continuity verification through complete signal paths to identify specific failure locations. Temperature sensor installations in harsh environments frequently experience connection degradation due to thermal cycling, chemical exposure, or mechanical stress that compromises electrical integrity. Understanding these failure mechanisms enables targeted inspection procedures that quickly identify connection problems and implement effective repairs that restore measurement accuracy.

Signal Drift and Calibration Errors

Temperature sensor drift manifests as gradual changes in measurement accuracy that develop over time due to material aging, contamination, or thermal stress effects on sensing elements. Drift detection requires comparison with reference standards or historical calibration data to identify sensors that exceed acceptable accuracy limits. Professional maintenance programs include regular calibration verification procedures that enable early detection of drift problems before they compromise process control or safety systems.

Calibration errors often result from improper installation, environmental contamination, or mechanical stress that affects sensor characteristics without causing complete failure. Temperature sensor troubleshooting procedures must distinguish between calibration issues and other error sources through systematic testing at known reference temperatures. Advanced diagnostic equipment enables field calibration verification that provides immediate assessment of sensor accuracy without requiring removal from service, reducing troubleshooting time while maintaining measurement system availability.

Environmental and Mechanical Failure Modes

Environmental exposure creates various temperature sensor failure modes including corrosion, contamination, and mechanical damage that affect measurement accuracy or cause complete sensor failure. Chemical attack on sensor housings, moisture ingress, and particulate contamination can gradually degrade performance or create sudden failures that require immediate attention. Professional troubleshooting includes environmental assessment procedures that identify exposure conditions contributing to sensor degradation and implement protective measures to prevent recurring problems.

Mechanical failures include housing cracks, element damage, and mounting system degradation that affect thermal coupling or expose sensing elements to harmful environmental conditions. Temperature sensor installations subject to vibration, thermal shock, or mechanical stress require specialized mounting and protection systems that prevent damage while maintaining measurement accuracy. Troubleshooting procedures must evaluate mechanical integrity through visual inspection, vibration testing, and thermal cycling assessment to identify structural problems requiring immediate attention.

Systematic Diagnostic Procedures for Rapid Problem Resolution

Step-by-Step Visual Inspection Protocol

Systematic visual inspection forms the foundation of effective temperature sensor troubleshooting, providing immediate identification of obvious problems while establishing baseline conditions for subsequent diagnostic procedures. Professional inspection protocols include comprehensive examination of sensor housings, connection terminals, mounting hardware, and environmental protection systems for signs of damage, corrosion, or degradation. Photographic documentation of sensor conditions enables tracking of degradation patterns and supports maintenance decision-making processes.

Advanced inspection techniques utilize specialized tools including borescopes, thermal imaging cameras, and magnification equipment to identify problems not visible through conventional examination methods. Temperature sensor installations in hazardous or inaccessible locations require remote inspection capabilities that enable condition assessment without exposing personnel to dangerous environments. Systematic documentation of inspection findings provides valuable data for trend analysis and predictive maintenance programs that prevent unexpected failures through proactive replacement of degraded components.

Electrical Testing and Measurement Verification

Electrical testing provides quantitative assessment of temperature sensor performance through resistance measurements, insulation testing, and signal analysis that identifies specific failure modes requiring corrective action. Professional testing procedures utilize calibrated instruments and standardized methods that ensure consistent results and enable comparison with manufacturer specifications or historical data. Resistance measurements at known temperatures provide immediate verification of sensor accuracy and identify drift problems that may not be apparent during normal operation.

Advanced testing equipment enables comprehensive signal analysis including noise measurements, response time evaluation, and dynamic performance assessment that identifies subtle problems affecting measurement quality. Temperature sensor troubleshooting benefits from portable calibration equipment that provides known temperature references for field verification without requiring laboratory conditions or extended downtime. Professional testing protocols include documentation requirements that support maintenance records and enable trend analysis for predictive maintenance planning.

Signal Path Analysis and System Integration Assessment

Temperature sensor troubleshooting must evaluate complete signal paths from sensing element to measurement display or control system to identify problems affecting measurement accuracy or system performance. Signal conditioning equipment, wiring systems, and measurement interfaces can introduce errors that appear as sensor problems but require different corrective actions. Professional diagnostic procedures include systematic testing of each signal path component to isolate specific failure locations and implement targeted repairs.

System integration issues often create temperature sensor errors through ground loops, electromagnetic interference, or improper signal conditioning that affects measurement accuracy without indicating sensor failure. Advanced troubleshooting techniques include signal analysis equipment that identifies interference sources and evaluates signal quality throughout measurement systems. Understanding system-level effects enables troubleshooting personnel to distinguish between actual sensor failures and integration problems that require different corrective approaches for permanent resolution.

Advanced Troubleshooting Tools and Preventive Maintenance Strategies

Professional Diagnostic Equipment Applications

Modern temperature sensor troubleshooting utilizes sophisticated diagnostic equipment that enables rapid problem identification and quantitative assessment of sensor performance characteristics. Precision multimeters with temperature coefficient measurement capabilities provide immediate evaluation of sensor accuracy and identify drift problems that indicate replacement requirements. Professional calibration equipment includes portable temperature sources that enable field verification of sensor accuracy under actual operating conditions without requiring system shutdown.

Advanced diagnostic tools include thermal imaging systems that identify temperature distribution problems, vibration analyzers that assess mechanical integrity, and data loggers that provide continuous monitoring for intermittent fault detection. Temperature sensor troubleshooting benefits from automated testing systems that perform comprehensive diagnostic sequences while documenting results for maintenance records and trend analysis. Professional diagnostic equipment investments typically provide rapid payback through reduced troubleshooting time and improved maintenance efficiency in critical temperature measurement applications.

Predictive Maintenance and Monitoring Systems

Predictive maintenance programs utilize continuous monitoring systems that track temperature sensor performance characteristics and provide early warning of developing problems before they cause system failures. Advanced monitoring systems analyze measurement data patterns, response characteristics, and environmental conditions to identify sensors approaching failure conditions that require proactive replacement. These systems significantly reduce unexpected downtime while optimizing maintenance scheduling and inventory management for temperature sensor installations.

Professional monitoring systems include automated alerting capabilities that notify maintenance personnel when sensor performance parameters exceed acceptable limits, enabling immediate corrective action before process disruption occurs. Temperature sensor monitoring data provides valuable information for reliability analysis, failure mode identification, and maintenance optimization that improves overall system performance. Integration with maintenance management systems enables automated work order generation and parts procurement that streamlines troubleshooting procedures and reduces response times.

Long-term Reliability Improvement Strategies

Effective temperature sensor troubleshooting includes analysis of failure patterns and root causes that enable implementation of design improvements and maintenance procedure modifications that prevent recurring problems. Professional reliability programs utilize failure data analysis to identify common problems and implement systematic solutions that address underlying causes rather than symptoms. This approach significantly reduces troubleshooting frequency while improving overall measurement system reliability and performance.

Advanced reliability improvement strategies include environmental monitoring systems that track conditions contributing to sensor degradation and implement protective measures that extend operational life. Temperature sensor selection criteria should include consideration of application-specific requirements, environmental conditions, and maintenance capabilities that optimize long-term performance while minimizing troubleshooting requirements. Professional reliability programs provide comprehensive approaches that balance initial costs with long-term maintenance requirements to achieve optimal total cost of ownership for critical temperature measurement systems.

Conclusion

Effective temperature sensor troubleshooting requires systematic approaches that combine visual inspection, electrical testing, and performance verification to rapidly identify and resolve measurement system problems. Professional diagnostic procedures utilize specialized equipment and standardized methods that enable quick fault isolation while implementing permanent solutions that prevent recurring failures. Advanced monitoring systems and predictive maintenance strategies provide proactive approaches that identify developing problems before they cause system disruption, optimizing maintenance efficiency while ensuring measurement system reliability in critical applications.

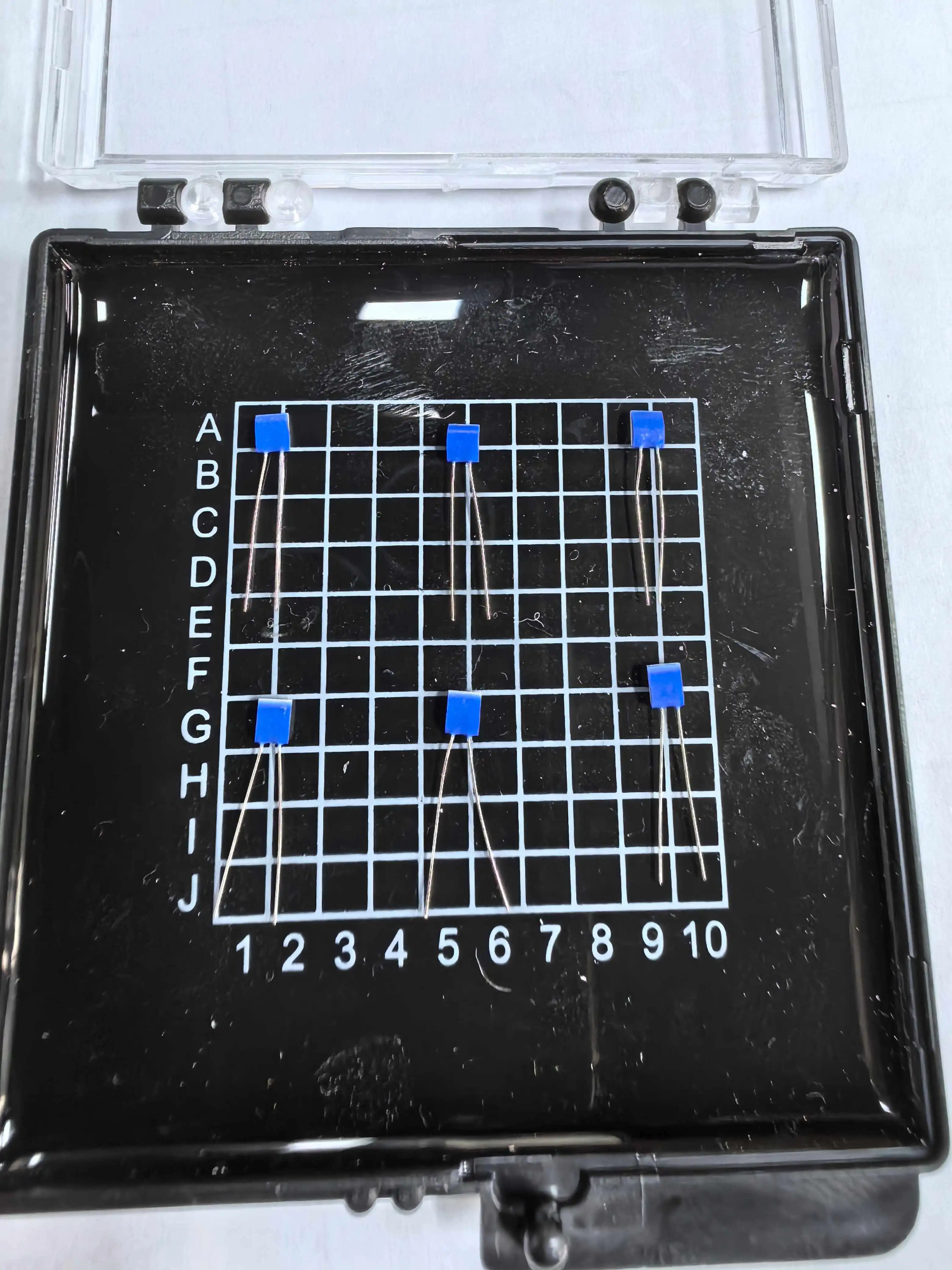

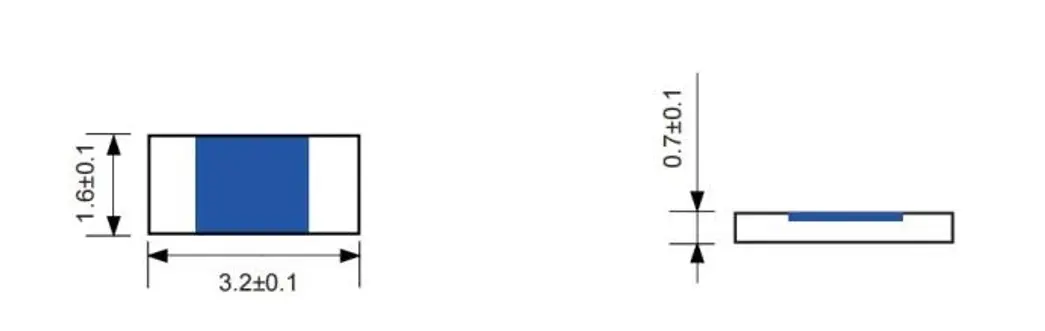

Xi'an Tongzida Technology Co., Ltd. stands as a leading manufacturer and supplier of advanced temperature sensor solutions, leveraging cutting-edge microsensor manufacturing technology and specialized packaging expertise to deliver superior measurement systems for demanding applications. Our comprehensive capabilities encompass thin film temperature sensor design, automated production lines, and rigorous quality control systems backed by ISO9001, ROHS, and CE certifications. As experienced temperature sensor suppliers serving diverse industrial markets, we understand the critical importance of reliable troubleshooting procedures and provide comprehensive technical support to help maintenance teams optimize sensor performance and minimize downtime.

Our high-resistance sensor designs offer enhanced signal-to-noise ratios and electromagnetic interference resistance that simplify troubleshooting while improving measurement reliability in challenging industrial environments. For procurement professionals seeking reliable temperature sensor manufacturers with proven expertise in troubleshooting support and technical service, contact our applications engineering team at sales11@xatzd.com to discuss your specific requirements and discover how our advanced temperature sensor solutions can enhance your measurement system reliability and reduce maintenance costs.

References

1. Morris, A.S. & Langari, R. (2021). Measurement and Instrumentation: Theory and Application. Academic Press, Engineering Systems Series, 3rd Edition.

2. Park, J. & Mackay, S. (2019). Practical Temperature Measurement: Troubleshooting and Maintenance Guide. Newnes, Industrial Instrumentation Handbook Series.

3. Webster, J.G. & Eren, H. (2020). Measurement, Instrumentation, and Sensors Handbook: Spatial, Mechanical, Thermal, and Radiation Measurement. CRC Press, 4th Edition.

4. Dunn, W.C. (2018). Introduction to Instrumentation, Sensors, and Process Control. Artech House Publishers, Industrial Electronics Series.

5. Bolton, W. (2021). Instrumentation and Control Systems: Troubleshooting and Maintenance. Newnes, Control Engineering Series, 3rd Edition.

Learn about our latest products and discounts through SMS or email