- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Installation and Maintenance Guide for PT1000 Platinum Thermistor: Avoiding 90% of On site Malfunctions

Installation and Maintenance Guide for PT1000 Platinum Thermistor: Avoiding 90% of On site Malfunctions

The on-site faults of PT1000 platinum thermistor are mainly caused by improper installation or maintenance negligence, rather than the sensor itself. For example, poor lead welding can cause reading jumps, and excessive tightening can lead to shell cracks. This article provides a detailed explanation of installation standards, daily maintenance steps, and troubleshooting methods to help reduce the risk of system downtime.

1. Pre installation inspection: parameter verification and environmental assessment

Parameter verification: Confirm that the nominal resistance (1000 Ω at 0 ℃) and TCR (3850 ppm/℃) of PT1000 match the instrument range.

Environmental adaptation: Avoid installing in strong electromagnetic fields or high-temperature corrosion points, and add insulation covers if necessary.

2. Mechanical installation specifications: Avoid stress damage

Lead connection: Two wire system is preferred (PT1000 wire resistance has a small impact), and silver palladium solder is used to prevent oxidation at the soldering points.

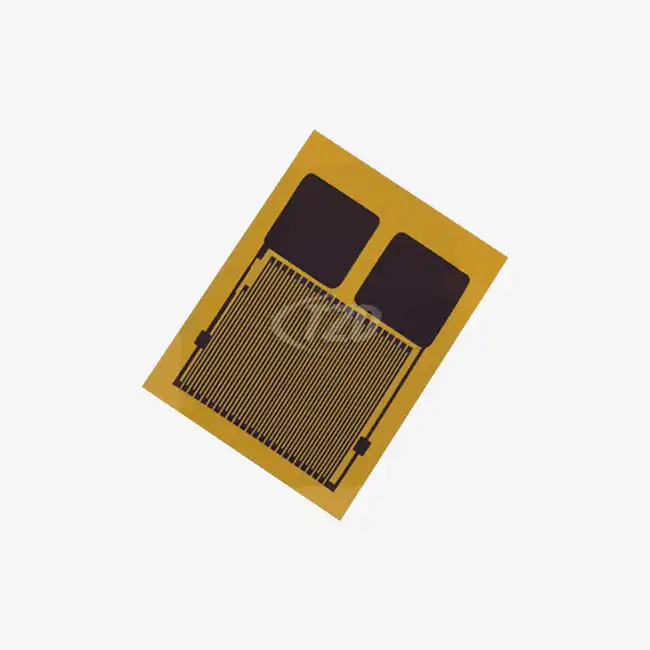

Torque control: When installing threads, the torque should be ≤ 5 N · m, and excessive tightening may cause deformation of the package (such as fragile components of 2.0mm × 2.3mm).

Flow direction optimization: Insert the counter current in the pipeline to improve response speed (such as t ₀ in the water flow) ₅ up to 0.05 seconds).

3. Daily maintenance and calibration cycle

Regular calibration: Verify the R ₀ value every 6 months, and recalibrate if drift>± 0.04%.

Cleaning method: Carbon deposits can be cleaned with anhydrous ethanol, and insulation resistance below 2 M Ω (at 500 ℃) indicates aging of the packaging.

4. Common troubleshooting table

Possible causes and solutions for the fault phenomenon: reading jumping, lead short circuit/poor contact. Check the junction box, re weld the lead point, slow response, probe scaling or air gap cleaning, ensure tight contact with the medium, over tolerance alarm, working current>0.3 mA. Adjust the constant current source to the range of 0.1-0.3 mA

Standardized installation and regular maintenance can extend the lifespan of PT1000 to over 10 years. The core lies in controlling mechanical stress, optimizing wiring, and periodic verification. For high-risk scenarios such as chemical reactors, it is recommended to adopt redundant design to enhance safety.

Author information: This article is written by a temperature sensor expert, based on the IEC 60751 standard and years of on-site service experience, aiming to help users reduce operation and maintenance costs.

CTA: If you need PT1000 selection templates or technical support, please feel free to contact us for free consultation.

FAQ:

Q1: Is the reading of PT1000 unstable after installation?

Check if the lead connections are secure and measure the insulation resistance (should be ≥ 100 M Ω).

Q2: Can I replace the lead wires myself?

Not recommended, non professional welding may alter TCR characteristics and require return to the factory for processing.

• Q3: What is the lifespan under high temperature conditions?

Under the correct selection (such as ceramic packaging), it can work stably for more than 3 years at 500 ℃.

Xi'an Tongzida Technology Co., Ltd. is a leading manufacturer and supplier of advanced thermistor technology, dedicated to providing high-performance temperature sensors for demanding industrial applications. We have comprehensive expertise in microsensor manufacturing technology, special packaging technology, and multi-sensor integration methods to ensure excellent performance and reliability of thermistors. As a trusted supplier of precision temperature measurement solutions, we offer a complete thermistor system, including core sensitive chips, testing systems, and analysis software. Please contact our technical experts sales11@xatzd.com Discuss your specific thermistor requirements and learn how our advanced resistor temperature optimization and manufacturing capabilities can improve the performance and reliability of your temperature measurement system

Learn about our latest products and discounts through SMS or email