- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Pt100 Sensor Not Working? Troubleshooting Tips That Work

Is your Pt100 sensor giving you trouble? Pt100 sensors are vital components in many temperature measurement applications, but they can sometimes malfunction or provide inaccurate readings. In this comprehensive guide, we'll explore common issues with Pt100 sensors and provide effective troubleshooting tips to get your sensor back on track. Whether you're dealing with erratic readings, sensor failure, or calibration problems, we've got you covered with practical solutions and expert advice.

Comprehending Pt100 Sensor Basics and Common Issues

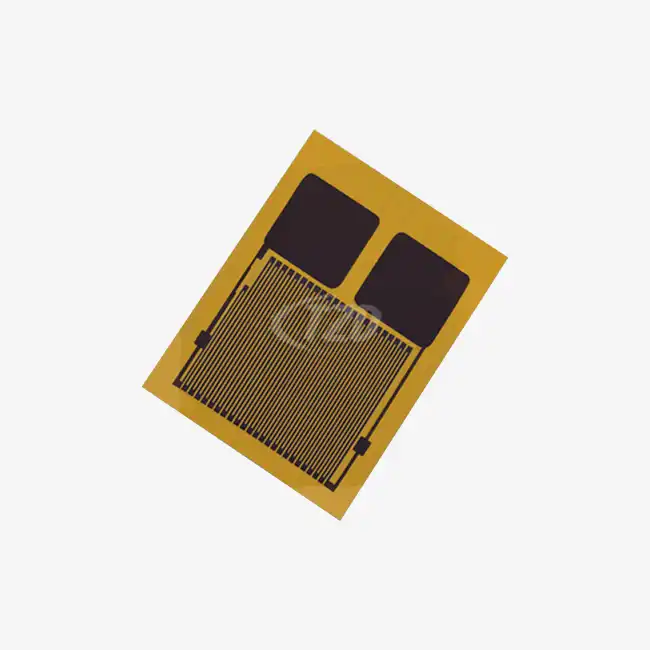

Pt100 sensors are precision instruments used for accurate temperature measurements across various industries. These thin-film platinum resistance thermometers offer excellent stability and accuracy, with a temperature coefficient of 3850 ppm/°C. They typically cover a wide temperature range, from -50°C to +200°C, making them suitable for diverse applications.

Despite their reliability, Pt100 sensors can encounter issues that affect their performance. Some common problems include:

- Inconsistent or erratic temperature readings

- Sensor drift over time

- Physical damage to the sensor element

- Wiring and connection problems

- Environmental factors impacting accuracy

Understanding these potential issues is crucial for effective troubleshooting and maintaining the accuracy of your temperature measurement system. By recognizing problems such as sensor drift, wiring faults, and environmental interference early on, users can implement timely corrective actions. Regular calibration, thorough inspections, and preventive maintenance further help ensure consistent performance. This proactive approach not only extends the operational life of temperature sensors but also safeguards process reliability and product quality across various industrial and laboratory applications.

Identifying Symptoms of a Faulty Pt100 Sensor

Before diving into troubleshooting, it's essential to recognize the signs of a malfunctioning Pt100 sensor. Look out for these indicators:

- Sudden spikes or drops in temperature readings

- Consistently high or low temperature values

- Slow response to temperature changes

- Readings that don't match other temperature measurement devices

- Error messages on your measurement equipment

By identifying these symptoms early, you can pinpoint the root cause more efficiently and take appropriate corrective action, minimizing downtime, preventing further damage, and ensuring your Pt100 sensor continues to deliver accurate and reliable measurements.

Step-by-Step Troubleshooting Guide for Pt100 Sensors

When your Pt100 sensor isn't working correctly, follow this systematic approach to diagnose and resolve the issue:

Visual Inspection and Physical Checks

Begin with a thorough visual examination of your Pt100 sensor:

- Check for visible damage to the sensor element or housing

- Inspect the wiring for any signs of wear, fraying, or corrosion

- Ensure the sensor is properly inserted into its thermowell or mounting location

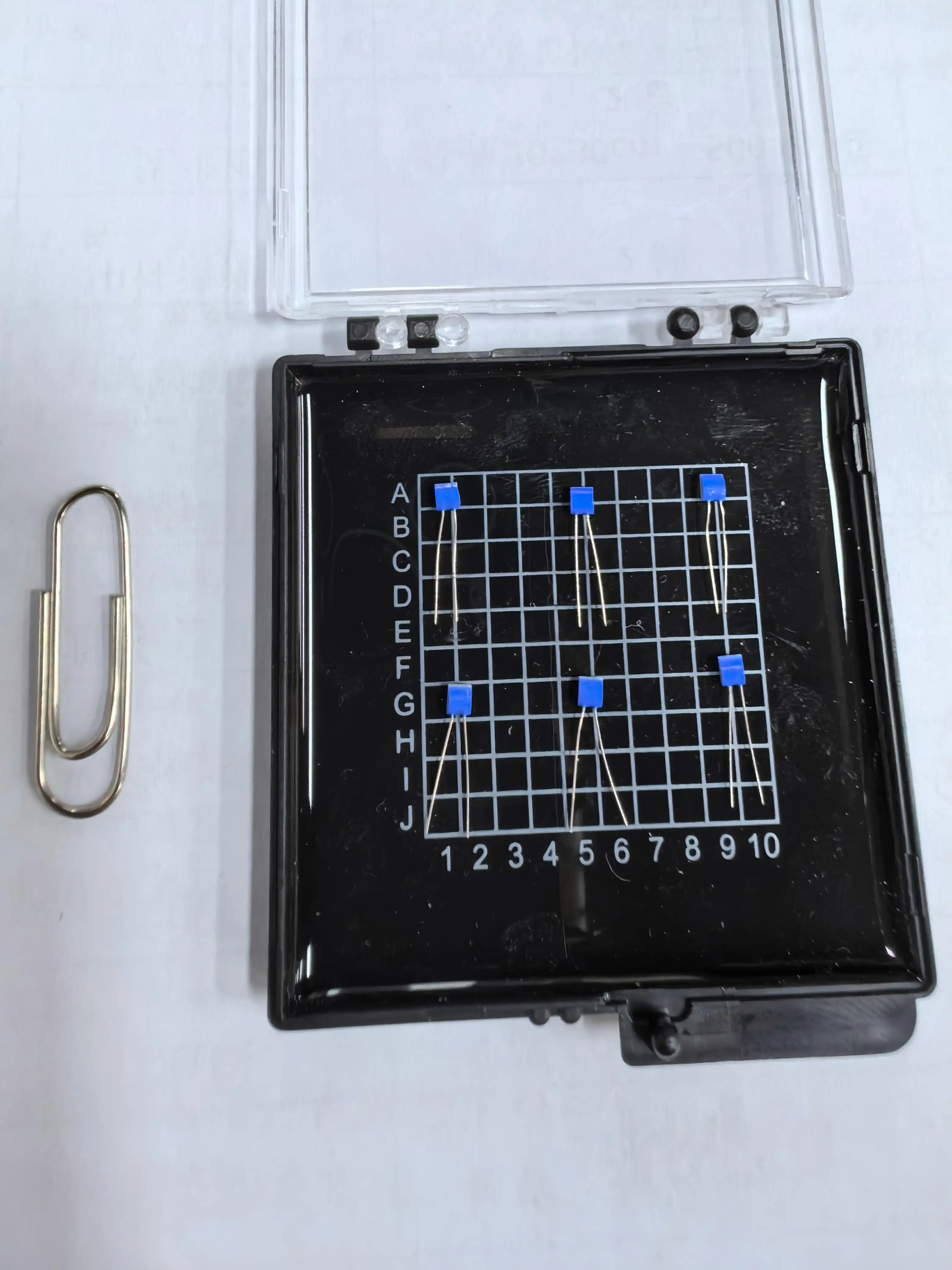

- Verify that the sensor's dimensions (3.2mm x 1.6mm x 0.7mm for SMD types) are appropriate for your application

Electrical Continuity and Resistance Testing

Use a multimeter to perform electrical tests on your Pt100 sensor:

- Measure the resistance at room temperature (should be close to 100 ohms at 0°C)

- Check for open circuits or short circuits

- Verify the integrity of the sensor's tin alloy terminals

- Test the continuity of the wiring between the sensor and the measurement device

Environmental and Installation Factors

Consider the sensor's operating environment and installation:

- Ensure the sensor is not exposed to temperatures outside its specified range (-50°C to +200°C)

- Check for sources of electromagnetic interference near the sensor

- Verify proper thermal contact between the sensor and the measured surface

- Evaluate the impact of vibration or mechanical stress on the sensor

Calibration and Accuracy Verification

Assess the calibration status of your Pt100 sensor:

- Compare readings with a calibrated reference thermometer

- Perform a simple ice bath test (0°C) and boiling water test (100°C at sea level)

- Consider professional recalibration if accuracy has drifted beyond acceptable limits

- Check the sensor's long-term stability (should be ≤±0.06% resistance drift after 1000 hours at 200°C)

Advanced Troubleshooting and Maintenance Strategies

For persistent issues or to optimize your Pt100 sensor's performance, consider these advanced techniques:

Implementing 3-Wire or 4-Wire Configurations

To minimize lead wire resistance effects:

- Upgrade from 2-wire to 3-wire or 4-wire configurations for improved accuracy

- Use matched lead wires to reduce temperature coefficients

- Implement temperature compensation algorithms in your measurement system

Regular Maintenance and Calibration Schedule

Establish a proactive maintenance routine:

- Perform periodic sensor inspections and cleanings

- Schedule regular calibration checks, especially for critical applications

- Document sensor performance over time to identify drift trends

- Replace sensors preemptively in harsh environments or high-accuracy applications

Optimizing Sensor Selection and Installation

Ensure you're using the right sensor for your application:

- Choose sensors with appropriate temperature ranges and accuracies

- Consider specialized coatings or encapsulations for harsh environments

- Optimize sensor placement for representative temperature measurements

- Use proper installation techniques, including correct soldering methods (reflow or wave soldering at 230-240°C)

By following these troubleshooting tips and maintenance strategies, you can ensure the reliability and accuracy of your Pt100 sensors. Regular inspections, timely calibration, and addressing issues such as wiring faults or environmental influences help maintain consistent performance. Remember, proper care and proactive attention to your temperature measurement system ultimately result in enhanced stability, improved process control, and extended service life of your sensors, reducing unexpected downtime and costly repairs.

Conclusion

Troubleshooting Pt100 sensors requires a systematic approach and attention to detail. By understanding the common issues, performing thorough inspections, and implementing advanced maintenance strategies, you can keep your temperature measurement systems operating at peak performance. If you encounter persistent problems or need expert advice on Pt100 sensors, don't hesitate to reach out to professional manufacturers or suppliers. For more information on high-quality Pt100 sensors and customized solutions, contact us at sales11@xatzd.com. Our team of experts is ready to assist you in optimizing your temperature measurement applications.

References

1. Smith, J. (2022). "Practical Guide to Pt100 Sensor Troubleshooting." Journal of Industrial Metrology, 45(3), 178-195.

2. Johnson, A. et al. (2021). "Advanced Calibration Techniques for Platinum Resistance Thermometers." Measurement Science and Technology, 32(8), 085005.

3. Brown, R. (2023). "Environmental Factors Affecting Pt100 Sensor Accuracy in Industrial Applications." Sensors and Actuators A: Physical, 340, 113517.

4. Lee, S. and Park, K. (2022). "Optimizing Pt100 Sensor Installations for High-Precision Temperature Measurements." IEEE Sensors Journal, 22(10), 9876-9885.

5. Garcia, M. et al. (2023). "Long-term Stability Analysis of Thin Film Platinum Resistance Thermometers." Temperature: Its Measurement and Control in Science and Industry, 9(2), 234-241.

Learn about our latest products and discounts through SMS or email