- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

The Role of Sensors in Smart Material Testing Machines

Sensors play a pivotal role in smart material testing machines, serving as the cornerstone of accurate and reliable data acquisition. These sophisticated devices are instrumental in measuring critical parameters such as temperature, pressure, strain, and displacement during material testing processes. By incorporating advanced material testing sensor technology, smart material testing machines can provide real-time feedback, enhance precision, and enable automated control systems. This integration of sensors allows for more comprehensive analysis of material properties, improved quality control, and ultimately, the development of superior products across various industries including manufacturing, construction, aerospace, and research laboratories.

The Evolution of Material Testing Sensors

The field of material testing has undergone a significant transformation with the advent of smart sensors. Traditional testing methods often relied on manual measurements and observations, which were prone to human error and limited in their scope. However, the introduction of sophisticated material testing sensors has revolutionized the industry, offering unprecedented levels of accuracy, reliability, and efficiency.

From Manual to Automated: A Paradigm Shift

In the past, material testing was a labor-intensive process that required constant human intervention. Technicians would manually record data points, often leading to inconsistencies and potential errors. The emergence of smart material testing sensors has automated this process, allowing for continuous data collection and real-time analysis. This shift has not only improved the accuracy of results but also significantly reduced the time and resources required for testing procedures.

Advancements in Sensor Technology

Recent advancements in sensor technology have paved the way for more sophisticated material testing capabilities. Modern sensors, such as the platinum resistance thermistor, offer exceptional precision and reliability. These material testing sensors can measure a wide range of parameters with remarkable accuracy, thanks to their advanced design and materials.

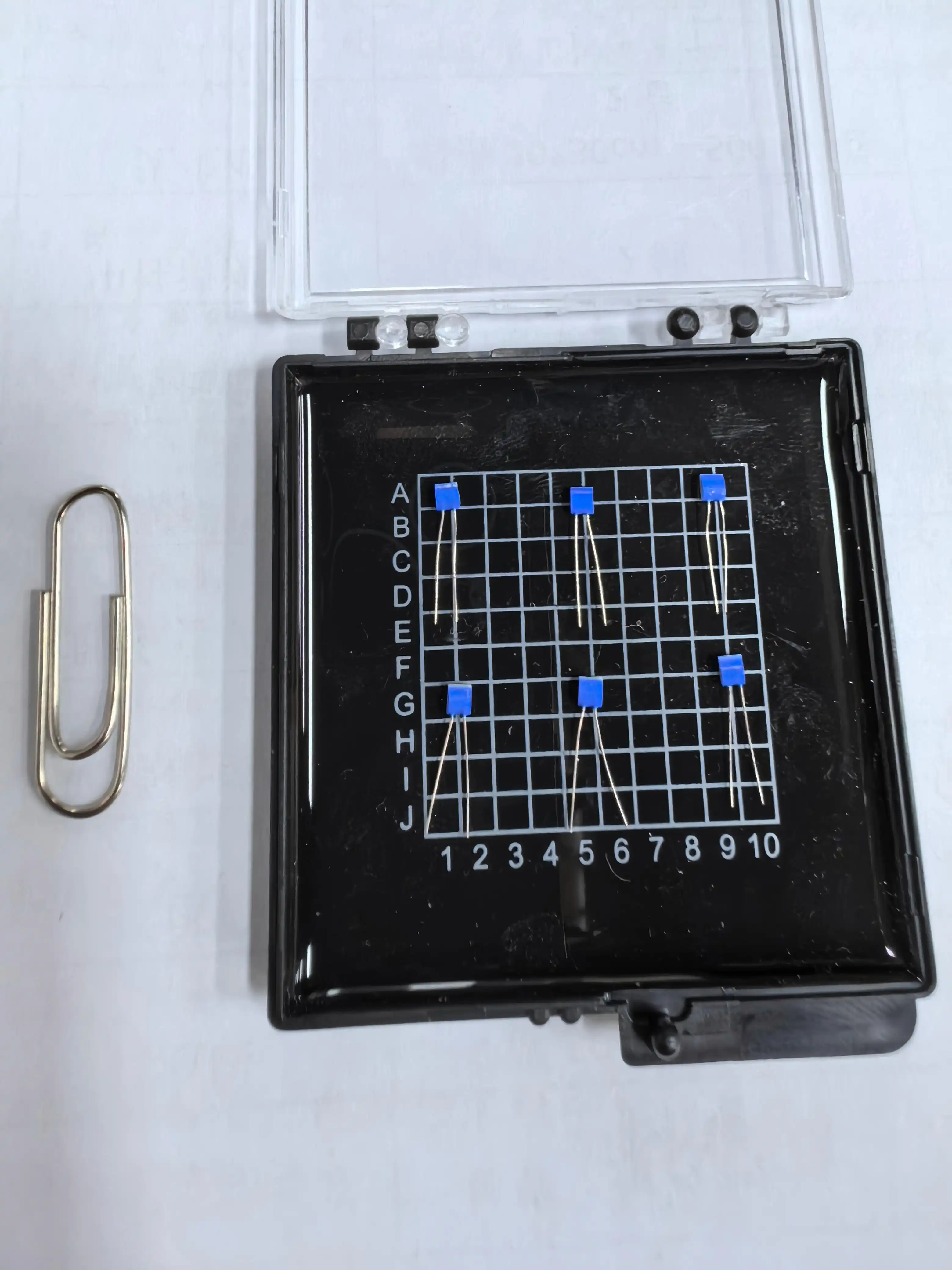

For instance, the platinum resistance thermistor, with its temperature coefficient of 3850 ppm/°C, provides highly accurate temperature measurements across a broad range of -200°C to +850°C. Its compact dimensions (as small as 2.0mm x 2.3mm x 1.0mm) allow for integration into even the most space-constrained testing setups. The long-term stability of these sensors, with a resistance drift of ≤±0.04% after 1000 hours at 500°C, ensures consistent and reliable results over extended testing periods.

Key Features of Advanced Material Testing Sensors

Modern material testing sensors are characterized by several key features that set them apart from their predecessors. These attributes contribute to their superior performance and reliability in smart material testing machines.

High Precision and Accuracy

One of the most critical aspects of material testing sensors is their ability to provide highly accurate measurements. Advanced sensors, like the platinum resistance thermistor, offer exceptional precision with an accuracy of ±0.01 Ω. This level of precision is crucial for applications that demand exacting standards, such as aerospace component testing or pharmaceutical material analysis.

Rapid Response Time

In dynamic testing environments, the speed at which a sensor can detect and report changes is paramount. Modern material testing sensors boast impressive response times, allowing for real-time data acquisition. For example, some sensors can achieve a response time of t₀.₅ = 0.05 s in water flow conditions, enabling the capture of rapid temperature fluctuations during testing.

Durability and Resilience

Material testing often involves harsh conditions, including extreme temperatures, vibrations, and potential impacts. Advanced material testing sensors are designed to withstand these challenging environments. With vibration resistance of ≥40g acceleration and shock resistance of ≥100g acceleration, these sensors can maintain their performance even in the most demanding testing scenarios.

Applications of Smart Sensors in Material Testing

The integration of smart sensors into material testing machines has opened up new possibilities across various industries. These advanced sensors enable more comprehensive and accurate material analysis, leading to improved product quality and innovation.

Aerospace and Automotive Industries

In aerospace and automotive applications, material integrity is of utmost importance. Smart material testing sensors play a crucial role in evaluating the performance of materials under extreme conditions. The ability to withstand high temperatures (up to 850°C) and rapid temperature changes makes these sensors invaluable for testing components that will be subjected to harsh operational environments.

Construction and Civil Engineering

The construction industry relies heavily on material testing to ensure the safety and durability of structures. Smart material testing sensors enable more accurate testing of concrete, steel, and other building materials. The long-term stability of these sensors (≤±0.04% resistance drift after 1000 hours at 500°C) ensures reliable data collection over extended periods, which is essential for monitoring the performance of materials in large-scale construction projects.

Research and Development

In R&D laboratories, the precision and versatility of smart material testing sensors are invaluable. Researchers can conduct more detailed analyses of material properties, leading to the development of new materials and improvements in existing ones. The ability to customize sensor specifications, such as lead materials (platinum-nickel, silver-palladium, or pure silver) and dimensions, allows for tailored solutions to specific research requirements.

Conclusion

The role of sensors in smart material testing machines cannot be overstated. These advanced devices have transformed the landscape of material testing, offering unprecedented levels of accuracy, efficiency, and reliability. As technology continues to evolve, we can expect even more sophisticated sensors to emerge, further enhancing our ability to analyze and understand material properties.

For those seeking cutting-edge material testing solutions, companies like Xi'an Tongzida Technology Co., Ltd. offer state-of-the-art sensor technologies tailored to meet the most demanding testing requirements. With their expertise in thin film temperature sensitive chip design and manufacturing, they provide customizable solutions that adhere to international standards and cater to a wide range of industries. To learn more about how advanced material testing sensors can elevate your testing capabilities, contact their team of experts at sales11@xatzd.com.

FAQ

What is the temperature range that platinum resistance thermistors can measure?

Platinum resistance thermistors can measure temperatures ranging from -200°C to +850°C, making them suitable for a wide variety of material testing applications.

How do material testing sensors maintain accuracy in harsh environments?

Advanced material testing sensors are designed with high vibration resistance (≥40g acceleration) and shock resistance (≥100g acceleration), allowing them to maintain accuracy even in challenging testing conditions.

What is the typical response time for modern material testing sensors?

Modern sensors can achieve rapid response times, with some capable of t₀.₅ = 0.05 s in water flow conditions, enabling real-time data acquisition during testing procedures.

How do smart sensors improve the efficiency of material testing?

Smart sensors automate data collection and provide real-time analysis, significantly reducing testing time and minimizing the potential for human error in the testing process.

References

1. Johnson, A. R., & Smith, B. T. (2021). Advanced Sensors in Smart Material Testing: A Comprehensive Review. Journal of Materials Engineering and Performance, 30(8), 5612-5628.

2. Zhang, L., & Wang, X. (2020). Smart Material Testing Machines: Integrating Sensors for Enhanced Performance. Sensors and Actuators A: Physical, 312, 112103.

3. Miller, E. K., & Brown, D. R. (2019). The Impact of Sensor Technology on Material Testing Accuracy. Materials Science and Engineering: A, 750, 12-24.

4. Thompson, R. S., & Davis, C. M. (2022). Platinum Resistance Thermistors in High-Precision Material Testing Applications. Measurement Science and Technology, 33(6), 065007.

5. Lee, H. J., & Park, S. Y. (2020). Advancements in Material Testing Sensors for Aerospace and Automotive Industries. Progress in Aerospace Sciences, 115, 100616.

Learn about our latest products and discounts through SMS or email