The Evolution of Temperature Sensing Technology

Temperature sensing technology has come a long way since the invention of the first thermometer. Traditional temperature sensors, while effective in many applications, often struggle with irregular surfaces or confined spaces. This limitation led to the development of ultra-thin flexible temperature sensors, which have overcome these challenges through innovative design and advanced materials.

These cutting-edge sensors utilize thin-film innovation, permitting for mind blowing adaptability without relinquishing execution. The ultra-thin plan, now and then as thin as 0.05mm, empowers these sensors to be connected to nearly any surface, in any case of its ebb and flow or complexity. This flexibility has opened up modern conceivable outcomes in different businesses, from car to therapeutic.

One of the key advancements in this field is the improvement in temperature coefficient (TCR). Modern ultra-thin flexible temperature sensors boast a TCR of 6444 ppm/°C, ensuring high sensitivity and accurate readings across a broad temperature range. This level of precision is crucial in applications where even small temperature variations can have significant impacts.

Advantages of Ultra-Thin Flexible Temperature Sensors

The benefits of these advanced sensors extend beyond their flexibility. They offer several advantages over traditional temperature sensing methods:

- Minimal thermal mass, leading to faster response times

- Excellent thermal coupling with measured surfaces

- Ability to measure temperature in hard-to-reach areas

- Resistance to vibration and shock, with some models withstanding up to 40g of vibration and 100g of impact

- Long-term stability, with drift as low as 0.04% over time

These characteristics make ultra-thin adaptable temperature sensors perfect for applications requiring exact, solid temperature estimations in challenging situations.

Applications Across Industries

The versatility of ultra-thin flexible temperature sensors has led to their adoption across a wide range of industries. Their ability to conform to complex curved surfaces has made them particularly valuable in sectors where traditional sensors fall short.

In the aerospace industry, these sensors play a crucial role in monitoring the temperature of aircraft components, including engine parts and wing surfaces. Their thin profile allows for seamless integration without affecting aerodynamics, while their ability to withstand extreme conditions ensures reliable operation at high altitudes and speeds.

The restorative field has moreover grasped this innovation. Ultra-thin adaptable temperature sensors are utilized in wearable wellbeing screens, giving exact body temperature readings without causing distress to the wearer. In surgical settings, these sensors can be connected specifically to rebellious or indeed quiet tissue, advertising real-time temperature checking amid sensitive strategies.

In the automotive industry, these sensors find applications in battery management systems for electric vehicles, helping to optimize performance and prevent overheating. Their flexibility allows them to be integrated into the curved surfaces of battery cells, providing precise temperature data for each unit.

Customization and Versatility

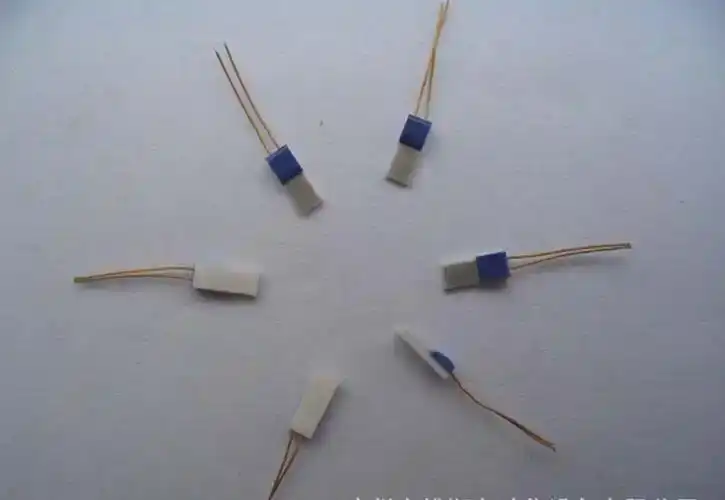

One of the key strengths of ultra-thin flexible temperature sensors is their customizability. Manufacturers offer these sensors in a range of sizes, typically from 1.2mm to 4.0mm, allowing for tailored solutions to specific application needs. The choice of lead materials, including platinum nickel, silver nickel, and pure platinum, further enhances their versatility.

This customization extends to the sensor's performance characteristics as well. Depending on the application requirements, these sensors can be produced with different accuracy grades. Class A sensors offer an accuracy of ±0.6°C, while Class B sensors provide ±1.2°C accuracy. This flexibility allows engineers to balance precision and cost-effectiveness in their designs.

Future Trends and Innovations

As technology continues to advance, the future of ultra-thin flexible temperature sensors looks promising. Researchers and manufacturers are working on several fronts to further improve these devices and expand their applications.

One area of focus is the development of even thinner sensors without compromising on performance. By reducing the thickness below the current 0.05mm standard, these sensors could be integrated into an even wider range of products and surfaces.

Another trend is the integration of these sensors with other technologies. For instance, combining ultra-thin flexible temperature sensors with wireless communication modules could enable real-time temperature monitoring in remote or hard-to-access locations. This could have significant implications for industries such as agriculture, where soil temperature monitoring is crucial for crop management.

Advancements in materials science are also driving innovation in this field. New materials with improved thermal properties and flexibility are being explored, which could lead to sensors with even greater accuracy and durability.

The Role of Artificial Intelligence and Machine Learning

The integration of manufactured insights (AI) and machine learning (ML) with ultra-thin adaptable temperature sensors is another energizing region of improvement. AI calculations might be utilized to analyze temperature information from these sensors, giving prescient upkeep experiences in mechanical settings or early caution frameworks for potential gear disappointments.

In medical applications, ML could help interpret temperature data from wearable sensors, potentially identifying patterns that indicate the onset of illness before other symptoms appear. This could revolutionize preventive healthcare and patient monitoring. As these technologies continue to evolve, we can expect to see ultra-thin flexible temperature sensors becoming even more integral to our daily lives and various industries.

Conclusion

Ultra-thin flexible temperature sensors represent a significant leap forward in temperature measurement technology. Their ability to conform to complex curved surfaces while providing accurate and reliable temperature readings has made them invaluable across numerous industries. From aerospace to healthcare, these sensors are enabling new applications and improving existing processes.

As we look to the future, the potential for further innovation in this field is immense. With ongoing advancements in materials science, manufacturing techniques, and integration with other technologies, ultra-thin flexible temperature sensors are set to play an even more crucial role in our increasingly technology-driven world.

For those interested in exploring the possibilities of ultra-thin flexible temperature sensors for their specific applications, expert guidance is available. To learn more about these innovative sensors and how they can benefit your projects, please contact us at sales11@xatzd.com. Our team of specialists is ready to assist you in finding the perfect temperature sensing solution for your needs.