The Fundamentals of Pt1000 Temperature Sensors

Pt1000 temperature sensors are a type of Resistance Temperature Detector (RTD) that utilize the temperature-dependent resistance properties of platinum. These sensors are renowned for their accuracy, stability, and wide temperature range, making them indispensable in numerous industries and applications.

Composition and Construction

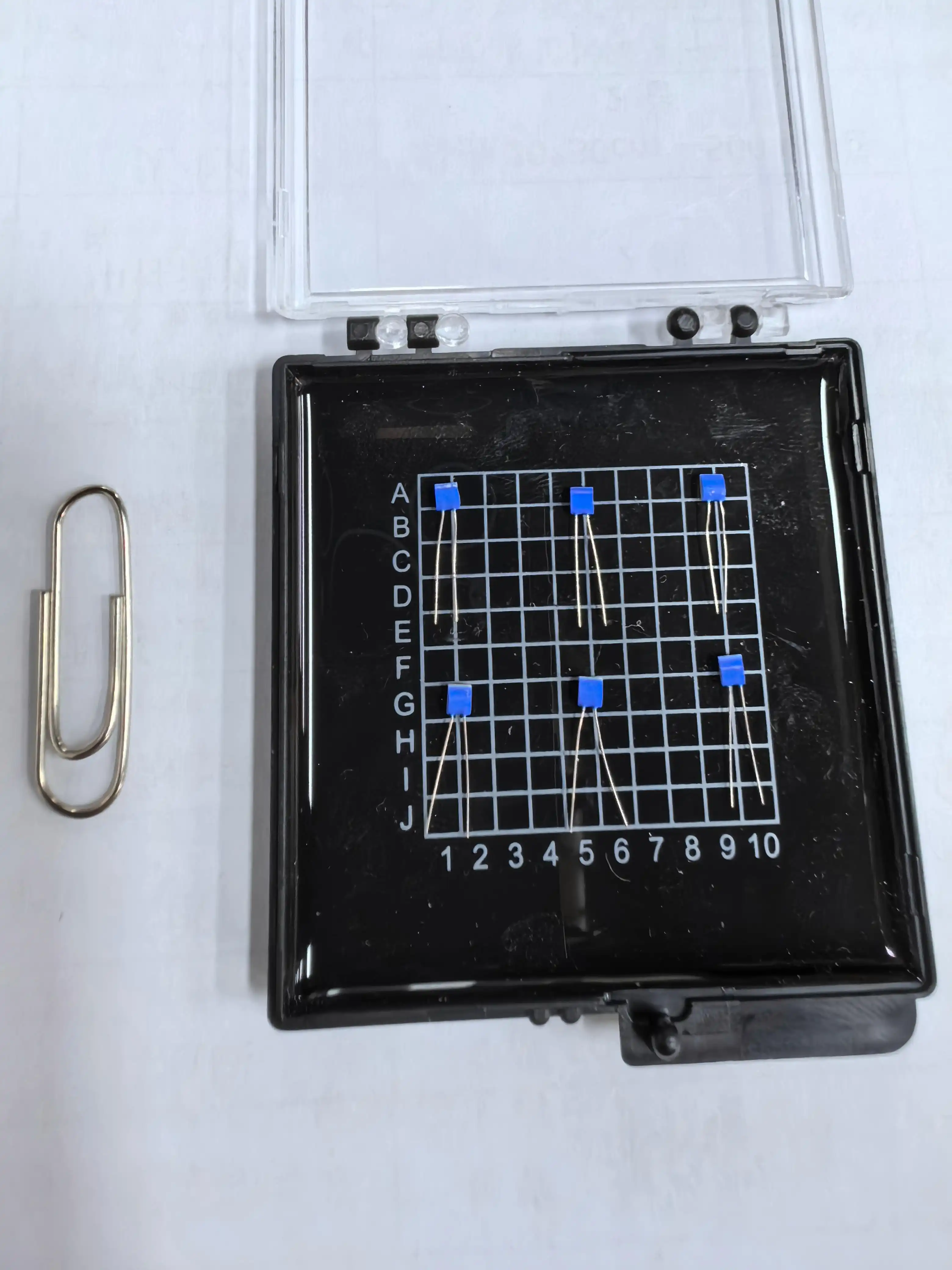

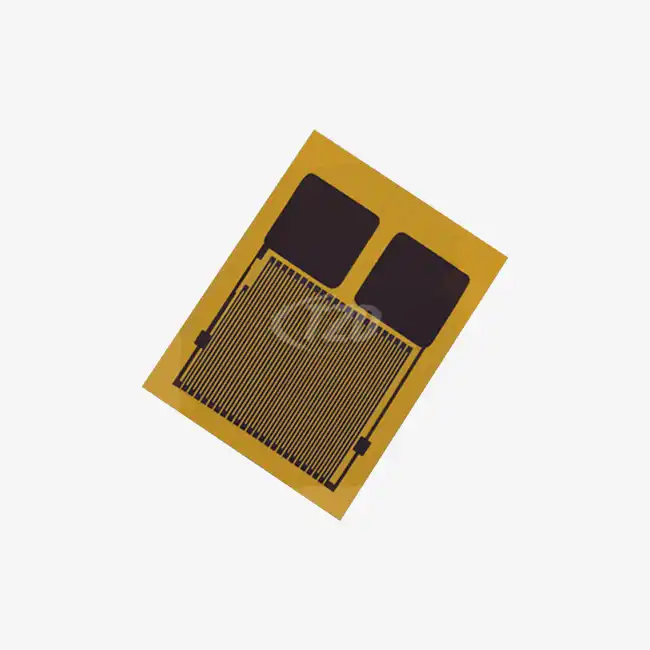

The heart of a Pt1000 sensor is a thin film of platinum carefully deposited on a durable ceramic substrate. This precise construction method enables significant miniaturization without sacrificing measurement accuracy or reliability. Typical sensor dimensions, such as 2.0mm x 2.3mm x 1.0mm or 2.0mm x 4.0mm x 1.0mm, make them ideally suited for integration into space-constrained medical, industrial, and electronic applications. The platinum film connects to lead wires usually crafted from platinum-nickel alloy, although silver-palladium or pure silver variants can be selected for specialized requirements like lower thermal EMF or higher corrosion resistance.

Operating Principles

Pt1000 sensors work on the well-established principle that the electrical resistance of platinum varies in a highly predictable and linear manner with temperature changes. As temperature rises, so does the resistance of the platinum element. This relationship is defined by the Temperature Coefficient of Resistance (TCR), typically around 3850 ppm/°C for Pt1000 sensors. This means each 1°C temperature increase leads to a resistance rise of about 0.385% from its baseline at 0°C, ensuring precise and repeatable temperature measurement.

Performance Characteristics

Pt1000 temperature sensors boast impressive performance characteristics. They offer excellent long-term stability, with resistance drift of R₀ (0°C reference) not exceeding ±0.04% after 1000 hours at 500°C. Their response time is remarkably quick, with t₀.₅ (time to reach 50% of the final value) as low as 0.05 seconds in flowing water. These sensors also demonstrate robust resistance to vibration and shock, withstanding accelerations of 40g and 100g respectively.

Interpreting the Resistance Curve

The resistance curve of a Pt1000 sensor is the graphical representation of how its resistance changes with temperature. Understanding this curve is crucial for accurate temperature measurements and proper sensor calibration.

The Callendar-Van Dusen Equation

The relationship between resistance and temperature in Pt1000 sensors is described by the Callendar-Van Dusen equation. This equation provides a mathematical model for the resistance-temperature curve, allowing for precise temperature calculations based on measured resistance values. The equation takes into account the slight non-linearity of the resistance curve, especially at extreme temperatures.

Linearity and Accuracy

While the resistance curve of Pt1000 sensors is nearly linear, there are slight deviations, particularly at very high or low temperatures. These deviations are well-documented and can be compensated for in the measurement circuitry or software. The high linearity of Pt1000 sensors contributes to their excellent accuracy, which can be as precise as ±0.01 Ω in resistance measurements.

Temperature Range and Resistance Values

Pt1000 sensors offer an expansive temperature measurement range from -200°C to +850°C. At 0°C, the sensor has a nominal resistance of 1000 ohms. This resistance increases to approximately 1385 ohms at 100°C and 2000 ohms at 266°C. Understanding these resistance values at key temperature points is essential for proper sensor calibration and measurement interpretation.

Applications and Considerations

The unique properties of Pt1000 temperature sensors make them suitable for a wide range of applications across various industries. Their reliability and accuracy are particularly valuable in demanding environments.

Industrial and Scientific Applications

In industrial settings, Pt1000 sensors are used for process control, equipment monitoring, and quality assurance. Their ability to withstand harsh conditions, including high temperatures and vibrations, makes them ideal for use in manufacturing plants, chemical processing facilities, and power generation systems. In scientific research, these sensors provide the precision necessary for accurate temperature control in laboratories and experimental setups.

Medical and Pharmaceutical Uses

The medical and pharmaceutical industries rely on Pt1000 sensors for applications requiring high accuracy and quick response times. These include monitoring critical equipment performance, controlling sterilization cycles to eliminate harmful microorganisms, and ensuring stable temperature conditions during drug formulation. Such precise control helps guarantee product safety, regulatory compliance, and consistent therapeutic effectiveness.

Automotive and Aerospace Engineering

In automotive applications, Pt1000 sensors are used for engine temperature monitoring, climate control systems, and battery management in electric vehicles. The aerospace industry utilizes these sensors for aircraft engine monitoring, environmental control systems, and in-flight data collection, leveraging their reliability under extreme conditions.

Considerations for Optimal Performance

To maximize the performance of Pt1000 temperature sensors, several factors must be considered. The operating current should be carefully controlled, typically between 0.1 and 0.3 mA, to minimize self-heating effects. The sensor's environment, including potential sources of electromagnetic interference, should be evaluated to ensure accurate readings. Regular calibration and proper wiring techniques are essential for maintaining long-term accuracy and reliability.

Conclusion

Understanding the resistance curve of Pt1000 temperature sensors is fundamental to their effective use across a multitude of applications. These sensors offer unparalleled accuracy, stability, and versatility, making them an indispensable tool in temperature measurement and control. As technology continues to advance, the role of Pt1000 sensors in ensuring precision and reliability in critical processes will only grow. For more information on Pt1000 temperature sensors and their applications, please contact us at sales11@xatzd.com.