Comprehending the Thin Film Platinum Resistor Pt300-DW

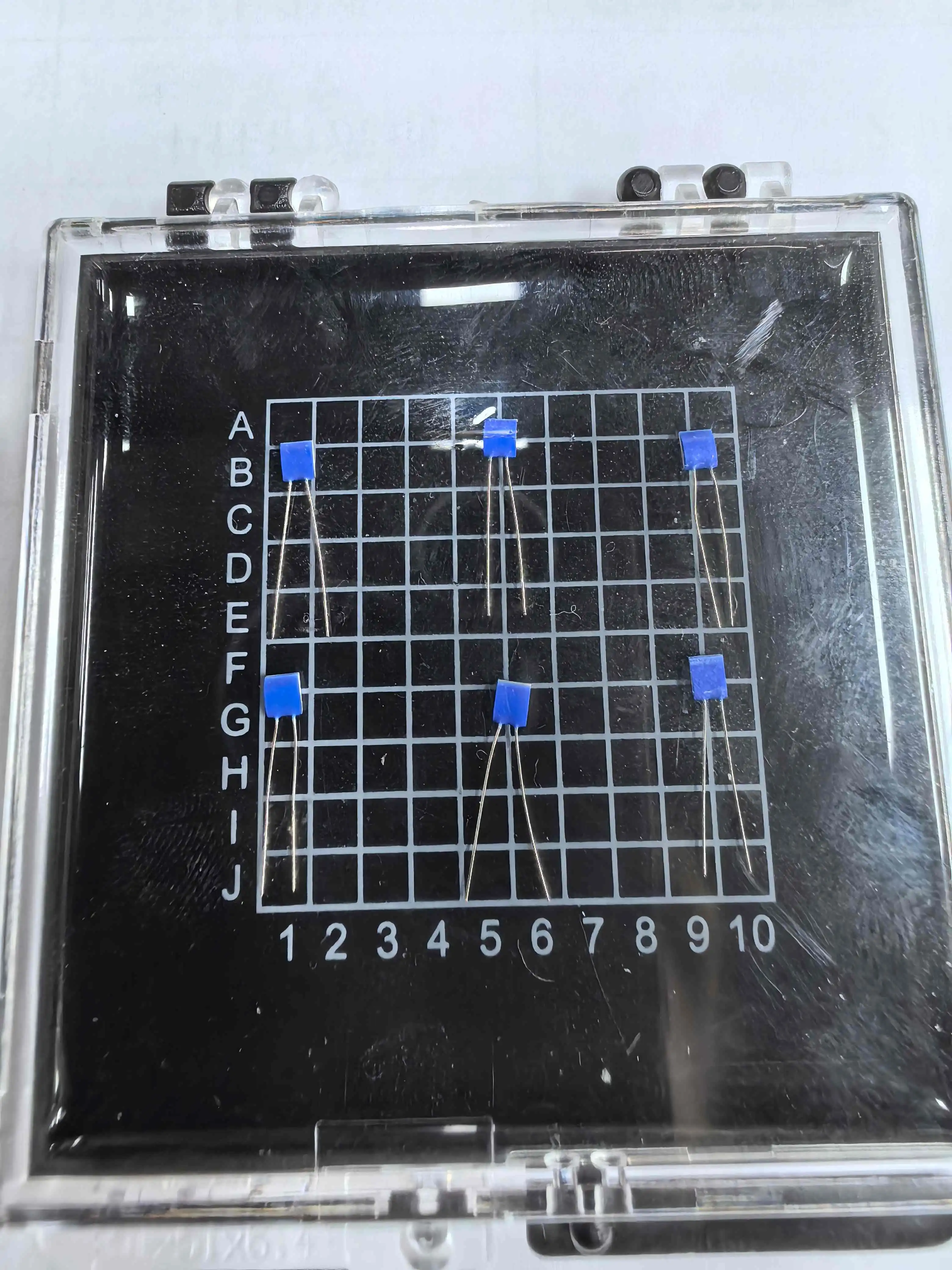

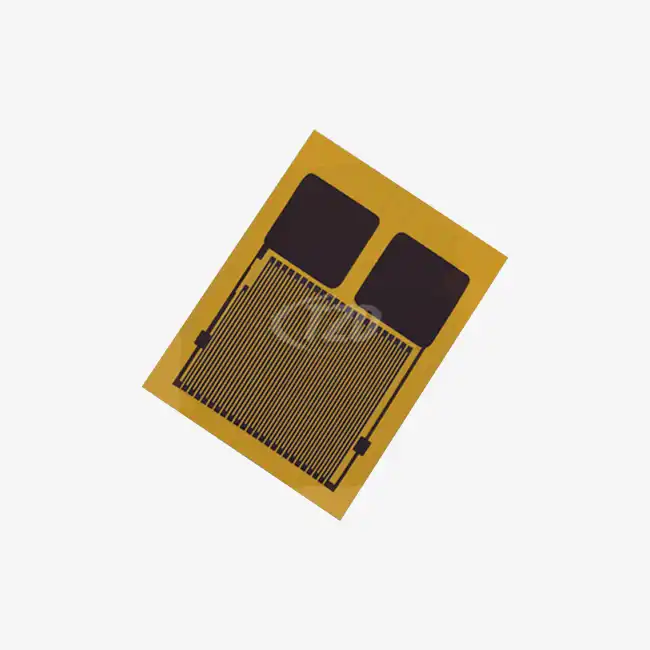

The Thin Film Platinum Resistor Pt300-DW is a highly precise temperature sensing device widely used in various industries. This resistor is designed with a thin film of platinum deposited on a ceramic substrate, offering excellent stability and accuracy in temperature measurements. The Pt300-DW model is particularly known for its compact size and robust performance across a wide temperature range.

One of the key features of the Pt300-DW is its temperature coefficient of resistance (TCR) of 3850 ppm/°C, which complies with the IEC60751 standard. This characteristic allows for precise temperature measurements and ensures consistency across different applications. The resistor's dimensions of 2.0mm x 3.0mm x 1.0mm make it suitable for use in space-constrained environments, while its lead specifications of 10 mm length and 0.2 mm diameter provide flexibility in installation.

The Thin Film Platinum Resistor Pt300-DW boasts impressive specifications that contribute to its reliability and accuracy. Its insulation resistance of 100 MΩ at 20°C and >2 MΩ at 500°C ensures minimal current leakage, even at high temperatures. The operating current range of 0.1-0.8 mA allows for versatile applications, though it's essential to consider the self-heating effect when selecting the appropriate current.

Long-term stability is a crucial factor in temperature sensing applications, and the Pt300-DW excels in this aspect. With a resistance drift of ≤±0.04% of R₀ (0°C reference) after 1000 hours at 500°C, users can rely on consistent performance over extended periods. This stability is particularly valuable in industrial processes where long-term accuracy is paramount.

Response Time and Environmental Resistance

The Pt300-DW's response time is impressive, with t₀.₅ = 0.05 s and t₀.₉ = 0.15 s in water flow (V=0.4 m/s), and t₀.₅ = 3 s and t₀.₉ = 10 s in airflow (V=2 m/s). These quick response times enable rapid temperature detection and control in dynamic environments. The self-heating coefficient of 0.4°C/mW at 0°C is another important parameter to consider when designing temperature measurement systems.

Environmental durability is a standout feature of the Pt300-DW. Its vibration resistance of ≥40g acceleration in the frequency range of 10-2000 Hz and shock resistance of ≥100g acceleration (8 ms half-sine wave) make it suitable for use in harsh industrial environments and automotive applications. This robustness ensures reliable performance even under challenging conditions.

Methods for Testing the Functionality of a Thin Film Platinum Resistor Pt300-DW

Ensuring the proper functioning of a Thin Film Platinum Resistor Pt300-DW is crucial for accurate temperature measurements. Several methods can be employed to verify its performance and reliability. These testing procedures help identify any potential issues and confirm that the resistor meets the required specifications.

Resistance Measurement at Room Temperature

One of the primary methods to check the functionality of a Pt300-DW is by measuring its resistance at room temperature. Using a high-precision multimeter, measure the resistance of the Pt300-DW at a known ambient temperature. Compare this value to the expected resistance calculated using the temperature coefficient of 3850 ppm/°C. The measured resistance should be within the specified tolerance range, typically ±0.01 Ω for high-quality resistors.

It's important to note that the lead resistance can affect the measurement accuracy, especially for low-resistance Pt300-DW models. To mitigate this, use a four-wire measurement technique, which eliminates the effect of lead resistance and provides more accurate results. This method is particularly useful when dealing with resistors that have long leads or when high precision is required.

Temperature Cycling Test

A temperature cycling test can reveal potential issues with the Pt300-DW's stability and performance across its operating range. Subject the resistor to a series of temperature cycles, ranging from its minimum to maximum specified temperatures. At each temperature point, measure the resistance and compare it to the expected value based on the temperature coefficient.

During this test, pay attention to any hysteresis effects or deviations from the expected resistance values. Significant discrepancies could indicate problems with the resistor's construction or materials. The long-term stability specification of ≤±0.04% resistance drift after 1000 hours at 500°C provides a benchmark for evaluating the resistor's performance over time.

Self-Heating Effect Evaluation

The self-heating effect can impact the accuracy of temperature measurements, especially when using higher currents. To evaluate this effect, apply different currents within the specified range of 0.1-0.8 mA and measure the resulting temperature rise. The self-heating coefficient of 0.4°C/mW at 0°C can be used as a reference point.

By comparing the observed temperature rise to the expected values based on the self-heating coefficient, you can verify if the Pt300-DW is behaving as expected. This test is particularly important for applications where high precision is required or where the resistor will be operated at higher currents.

Troubleshooting Common Issues with Thin Film Platinum Resistor Pt300-DW

Despite the robust design and high-quality manufacturing of the Thin Film Platinum Resistor Pt300-DW, issues may occasionally arise. Identifying and addressing these problems is crucial for maintaining accurate temperature measurements and ensuring the longevity of the device.

Drift and Stability Issues

One of the potential problems that may occur with the Pt300-DW is drift in resistance over time. While the specified long-term stability of ≤±0.04% resistance drift after 1000 hours at 500°C is excellent, factors such as contamination, mechanical stress, or exposure to extreme conditions can lead to deviations from this specification.

To troubleshoot drift issues, start by verifying the resistor's operating environment. Ensure that it's not exposed to temperatures beyond its rated range of -200°C to +850°C. Check for any sources of contamination or mechanical stress that could affect the thin film element. If drift persists, consider performing a recalibration or replacing the resistor if it's outside the acceptable tolerance range.

Insulation Resistance Degradation

The Pt300-DW's high insulation resistance (100 MΩ at 20°C, >2 MΩ at 500°C) is critical for accurate measurements. However, exposure to moisture, contaminants, or physical damage can lead to a degradation of this insulation resistance. This can result in current leakage and inaccurate temperature readings.

To address insulation resistance issues, first inspect the resistor and its leads for any visible signs of damage or contamination. Clean the resistor carefully if necessary, using appropriate solvents that won't damage the element or leads. Measure the insulation resistance using a high-voltage insulation tester, comparing the results to the specified values. If the insulation resistance remains low, the resistor may need to be replaced.

Lead Wire and Connection Problems

The Pt300-DW's lead wires, typically made of platinum-nickel alloy, are designed to withstand a tensile strength of ≥9 N. However, improper handling, excessive bending, or vibration can lead to lead wire damage or poor connections. This can result in erratic readings or open circuits.

When troubleshooting lead wire issues, visually inspect the leads for any signs of damage, kinks, or breaks. Use a continuity tester to check for any open circuits between the leads and the resistive element. If using extended leads or connectors, verify that all connections are secure and free from corrosion. In cases where lead damage is found, it may be possible to repair or replace the leads, depending on the specific installation and application requirements.

Conclusion

The Thin Film Platinum Resistor Pt300-DW is a highly reliable and accurate temperature sensing device. By understanding its characteristics, properly testing its functionality, and addressing common issues, users can ensure optimal performance in their temperature measurement applications. For further assistance or information about the Pt300-DW and other thin film platinum resistors, please contact our expert team at sales11@xatzd.com.