The Science Behind Thin Flexible Temperature Sensing Film

Thin flexible temperature sensing films represent a significant advancement in temperature measurement technology. These innovative sensors combine the benefits of traditional temperature sensing methods with the added advantage of flexibility, making them suitable for a wide range of applications. Understanding the science behind these films is crucial for appreciating their capabilities and potential uses.

Working Principle of Flexible Temperature Sensors

The fundamental principle behind thin flexible temperature sensing films is the change in electrical properties of materials in response to temperature variations. As the temperature fluctuates, the resistance or capacitance of the sensing material changes, allowing for precise temperature measurements. This phenomenon is known as the temperature coefficient of resistance (TCR) or temperature coefficient of capacitance (TCC), depending on the specific sensor design.

In the case of resistive temperature sensors, such as those using platinum or nickel, the resistance increases with temperature. The relationship between resistance and temperature is often linear within a specific range, making calibration and measurement straightforward. For example, platinum-based sensors typically have a temperature coefficient of 3850 ppm/°C, as specified by the IEC60751 standard.

Material Properties and Performance Characteristics

The choice of materials for thin flexible temperature sensing films significantly influences their performance characteristics. Platinum is a popular choice for high-precision temperature measurements due to its stability and linear response over a wide temperature range. Some sensors can operate from -200°C to +850°C with exceptional accuracy.

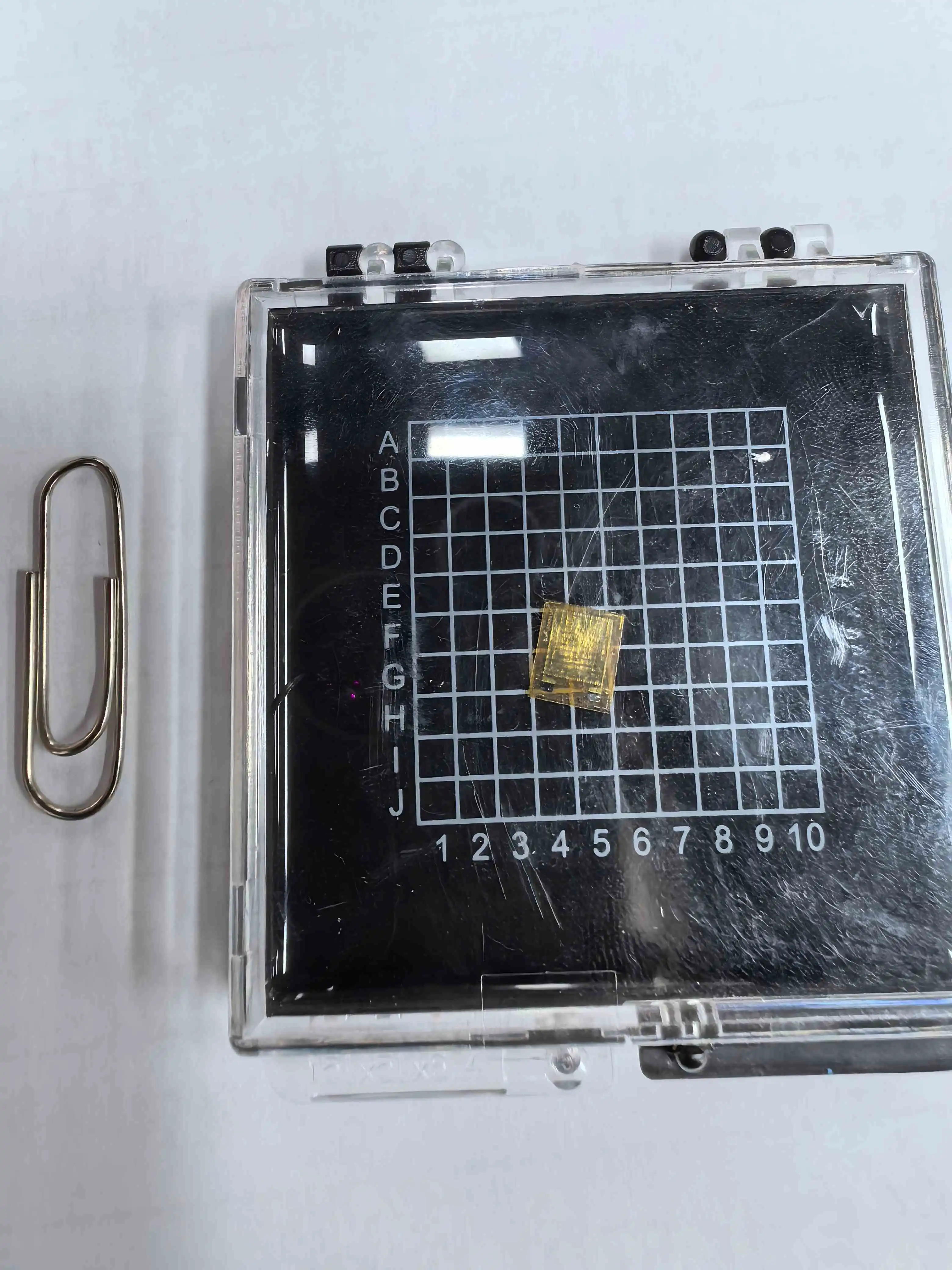

The dimensions of these sensors play a crucial role in their performance. For instance, a sensor with dimensions of 7mm x 5mm x 0.05mm offers a balance between size and sensitivity. The thickness of just 0.05mm ensures flexibility while maintaining durability. Manufacturers often provide customization options to tailor the sensor dimensions to specific application requirements.

Temperature measurement grades, such as Class A (±0.6°C) and Class B (±1.2°C), indicate the sensor's accuracy. These classifications help users select the appropriate sensor for their specific needs, balancing precision with cost considerations.

Advancements in Thin Film Technology

Recent advancements in thin film technology have led to the development of sensors with remarkable characteristics. Some modern thin film platinum resistors boast an accuracy of ±0.01 Ω and long-term stability drift of ≤ 0.04%. These improvements result from refined manufacturing processes and material selection.

The temperature coefficient (TCR) of 6444 ppm/°C in some sensors represents a significant improvement over traditional designs, offering enhanced sensitivity to temperature changes. This high TCR value allows for more precise measurements across a broader temperature range, typically from -70°C to +200°C in many applications.

Manufacturing Processes and Quality Control

The production of thin flexible temperature sensing films involves sophisticated manufacturing processes and rigorous quality control measures. These processes ensure the reliability, accuracy, and consistency of the sensors across various applications.

Advanced Manufacturing Techniques

Leading manufacturers employ state-of-the-art techniques in the production of thin film temperature sensors. The process typically begins with the design phase, where engineers use computer-aided design (CAD) software to optimize the sensor layout and characteristics. This is followed by the deposition of thin film materials onto the substrate using methods such as physical vapor deposition (PVD) or chemical vapor deposition (CVD).

The precise control of film thickness and composition is crucial for achieving the desired sensor properties. Advanced manufacturing lines utilize automated systems to ensure consistency and minimize human error. For instance, some production facilities can produce sensors with multiple size options ranging from 1.2mm to 4.0mm, catering to diverse application needs.

Packaging and Lead Materials

The packaging of thin flexible temperature sensing films is a critical aspect of their manufacturing process. The choice of pad material, such as tinned surfaces, affects the sensor's durability and ease of integration into electronic systems. Manufacturers offer various lead material options, including platinum nickel, silver nickel, and pure platinum, each with its own set of advantages for specific applications.

Special packaging techniques are employed to protect the delicate sensing elements while maintaining flexibility. These methods ensure that the sensors can withstand environmental challenges such as vibration and impact. Some advanced sensors boast vibration resistance of up to 40g and impact resistance of 100g, making them suitable for demanding industrial and automotive applications.

Quality Assurance and Certification

To ensure the highest quality standards, manufacturers implement comprehensive quality assurance programs. These programs often include in-line testing during production and final quality checks before packaging. Advanced testing platforms can assess sensor performance across a wide temperature range, from ultra-low to high temperatures.

Many reputable manufacturers have obtained certifications such as ISO9001 quality management system, RoHS compliance, and CE marking. These certifications not only demonstrate compliance with international standards but also provide customers with confidence in the product's quality and reliability.

Applications and Future Trends

Thin flexible temperature sensing films have found applications across various industries due to their unique properties and versatility. As technology continues to advance, new possibilities and trends are emerging in the field of temperature sensing.

Industrial and Scientific Applications

In industrial settings, thin flexible temperature sensors are utilized for process control, equipment monitoring, and safety systems. Their ability to conform to irregular surfaces makes them ideal for monitoring the temperature of rotating machinery, pipelines, and chemical reactors. The high accuracy and rapid response time of these sensors, sometimes as low as 0.05 seconds, enable real-time temperature monitoring and precise control in manufacturing processes.

Scientific research benefits from the high precision and stability of thin film temperature sensors. They are employed in laboratory equipment, environmental monitoring stations, and even space exploration missions where reliability under extreme conditions is paramount.

Medical and Healthcare Innovations

The medical field has embraced thin flexible temperature sensing films for various applications. These sensors can be integrated into wearable devices for continuous patient monitoring, providing healthcare professionals with valuable data for diagnosis and treatment. The flexibility and biocompatibility of these sensors make them suitable for direct contact with skin, enabling non-invasive temperature measurements.

In surgical settings, thin film temperature sensors assist in maintaining precise temperature control during procedures. Their small size and flexibility allow for placement in critical areas without interfering with the surgical process.

Emerging Trends and Future Developments

The future of thin flexible temperature sensing films looks promising, with several emerging trends shaping their development. Integration with Internet of Things (IoT) technologies is enabling remote monitoring and data analytics capabilities, enhancing predictive maintenance and process optimization in industrial applications.

Advancements in materials science are paving the way for even more sensitive and durable sensors. Research into new conductive polymers and nanocomposites may lead to sensors with improved flexibility, wider temperature ranges, and enhanced stability.

The miniaturization trend continues, with manufacturers working on ultra-thin sensors that can be seamlessly integrated into textiles, packaging materials, and electronic devices. This miniaturization opens up new possibilities for temperature sensing in consumer electronics, smart packaging, and environmental monitoring applications.

Conclusion

Thin flexible temperature sensing films represent a significant advancement in temperature measurement technology, offering unique advantages in terms of flexibility, accuracy, and versatility. As manufacturing processes continue to improve and new materials are developed, these sensors are poised to play an increasingly important role in various industries.

The combination of high precision, rapid response times, and durability makes thin flexible temperature sensing films an attractive option for a wide range of applications. From industrial process control to medical diagnostics and scientific research, these sensors are enabling new capabilities and improving existing processes.

As the demand for precise temperature monitoring in flexible and compact form factors continues to grow, manufacturers are responding with innovative solutions. For those interested in exploring the possibilities of thin flexible temperature sensing films or seeking customized solutions for specific applications, contacting industry experts is recommended. To learn more about cutting-edge temperature sensing technologies and how they can benefit your projects, reach out to us at sales11@xatzd.com.