- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What Features Should You Look for in a Vaccine Cold Chain Sensor?

When selecting a vaccine cold chain sensor, key features to consider include high accuracy, wide temperature range, rapid response time, durability, and data logging capabilities. The sensor should maintain precision in extreme temperatures, typically from -70°C to 8°C, to ensure vaccine efficacy. Look for sensors with minimal drift over time, robust construction to withstand transport conditions, and the ability to provide real-time temperature monitoring. Advanced features like wireless connectivity, cloud-based data storage, and customizable alerts can enhance the overall effectiveness of vaccine temperature management systems.

Grasping the Importance of Vaccine Cold Chain Sensors

Vaccine cold chain sensors play a crucial role in maintaining the efficacy and safety of vaccines throughout their journey from production to administration. These sophisticated devices are designed to monitor and record temperature fluctuations, ensuring that vaccines remain within their required temperature range. The importance of these sensors cannot be overstated, as even slight deviations from the optimal temperature can render vaccines ineffective or potentially harmful.

The vaccine cold chain is a complex system that involves multiple stages, including manufacturing, storage, transportation, and distribution. At each of these stages, vaccines are vulnerable to temperature excursions that could compromise their quality. This is where vaccine cold chain sensors come into play, providing continuous monitoring and real-time alerts to prevent temperature-related issues.

The Role of Sensor Technology in Vaccine Preservation

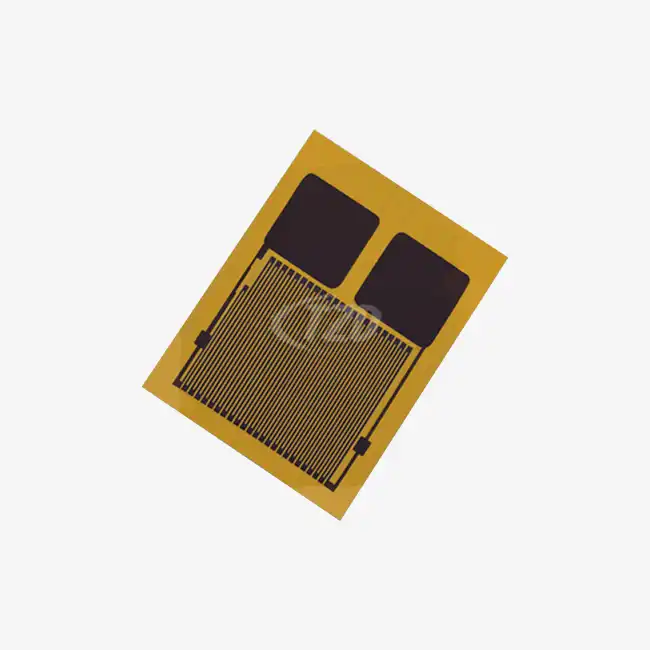

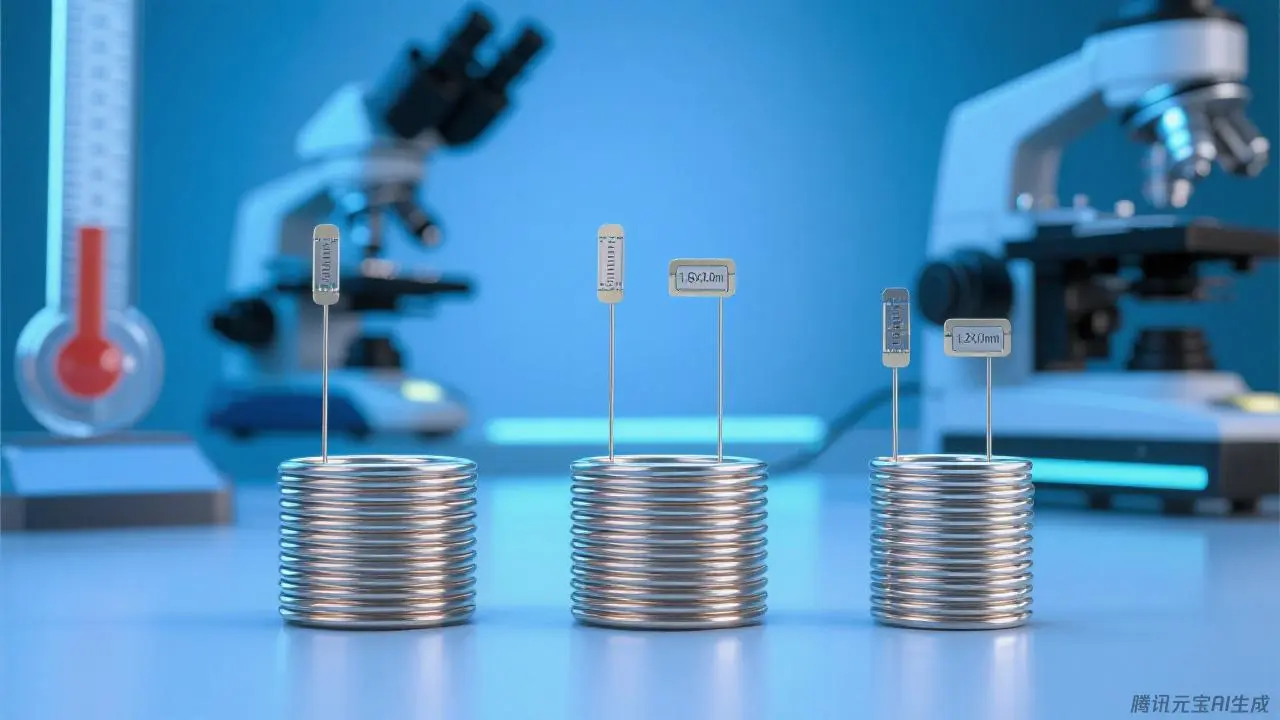

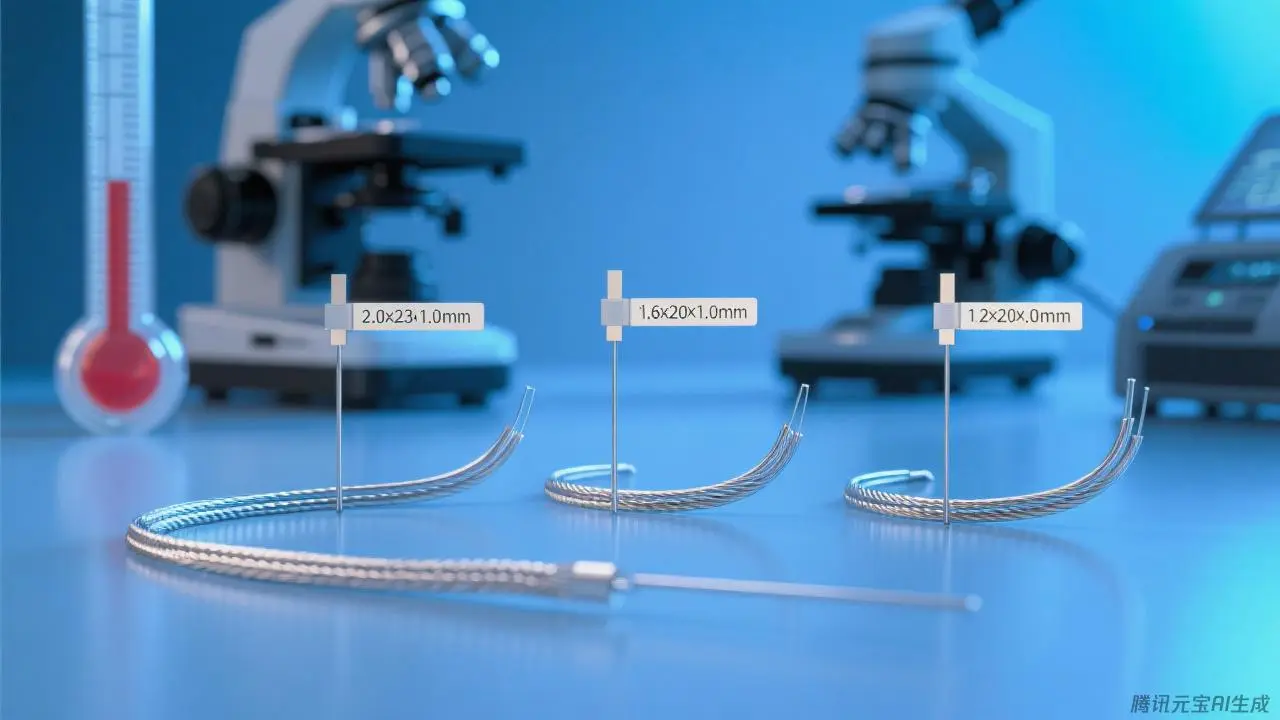

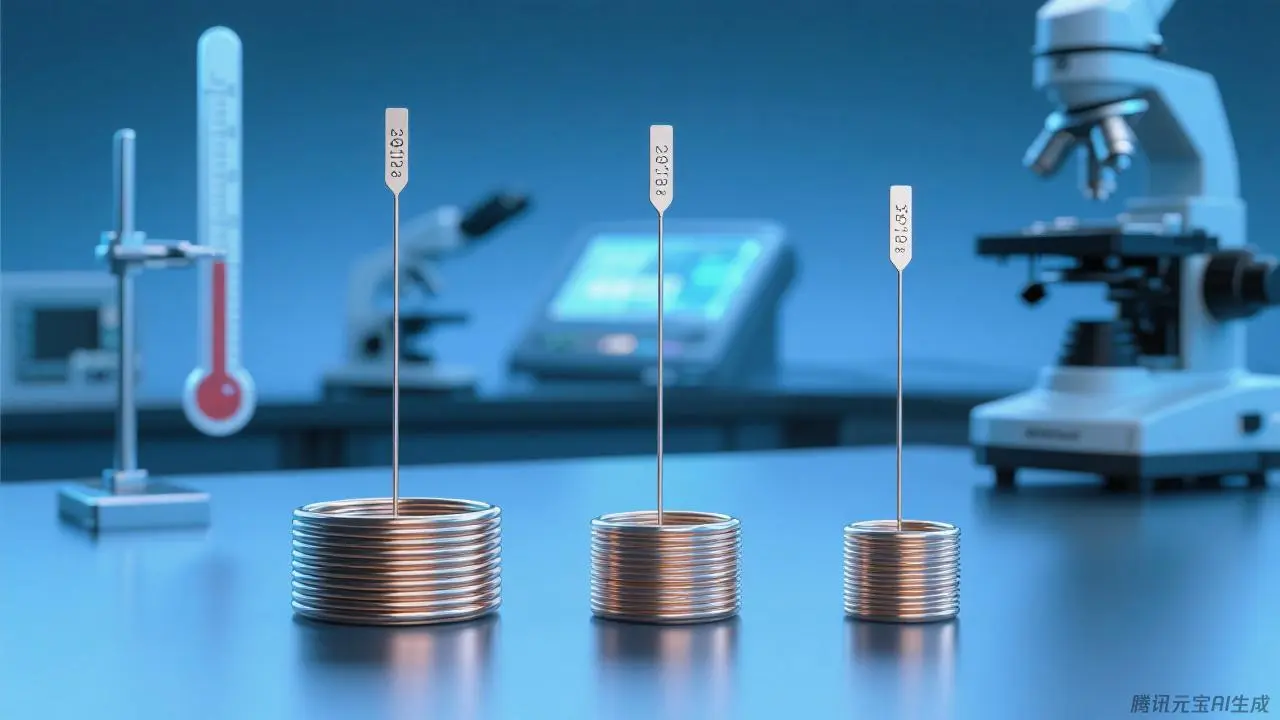

Advanced sensor technology has revolutionized the way we manage vaccine cold chains. Modern vaccine cold chain sensors utilize thin film platinum resistance thermistors, which offer exceptional accuracy and stability. These sensors can detect minute temperature changes, often with a precision of ±0.01°C, ensuring that any potential issues are identified immediately.

The thin film design allows for compact sensors that can be easily integrated into various vaccine storage and transport containers. With dimensions as small as 1.2mm x 2.0mm x 1.0mm, these sensors can be placed in strategic locations without interfering with vaccine packaging or storage systems. The platinum-nickel wire leads, with a length of 10mm and a diameter of 0.2mm, provide reliable connectivity and durability.

Critical Features of Effective Vaccine Cold Chain Sensors

When evaluating vaccine cold chain sensors, several critical features should be considered to ensure optimal performance and reliability. These features directly impact the sensor's ability to safeguard vaccine integrity throughout the cold chain process.

Temperature Range and Accuracy

An effective vaccine cold chain sensor must operate accurately across a wide temperature range. Many vaccines require storage at temperatures as low as -70°C, while others need to be maintained just above freezing. The sensor should maintain its accuracy across this entire spectrum, with a temperature coefficient (TCR) of around 3850 ppm/°C, ensuring consistent performance in various environments.

Accuracy is paramount, as even small temperature deviations can impact vaccine efficacy. Look for sensors with a high level of precision, typically offering an accuracy of ±0.01°C or better. This level of accuracy is crucial for detecting subtle temperature changes that could indicate potential issues in the cold chain.

Response Time and Stability

Quick response time is essential for timely intervention in case of temperature excursions. Advanced vaccine cold chain sensors can achieve response times as low as 0.05 seconds (t0.5) in flowing conditions, allowing for near-instantaneous detection of temperature changes. This rapid response enables immediate corrective actions to be taken, potentially saving valuable vaccine doses.

Long-term stability is equally important. High-quality sensors exhibit minimal drift over time, with some models showing less than ±0.04% resistance drift after 1000 hours of operation at 500°C. This stability ensures that the sensor remains reliable throughout the entire vaccine distribution process, which can span several months.

Advanced Capabilities for Comprehensive Cold Chain Management

Modern vaccine cold chain sensors offer advanced capabilities that go beyond basic temperature monitoring. These features enhance the overall management of the vaccine cold chain, providing greater control and insight into the entire process.

Data Logging and Connectivity

Data logging capabilities are essential for maintaining a complete temperature history of vaccine shipments. Advanced sensors can store thousands of temperature readings, creating a detailed record of the cold chain environment. This data is invaluable for quality assurance, regulatory compliance, and troubleshooting any issues that may arise.

Connectivity options, such as wireless data transmission and cloud-based storage, allow for real-time monitoring and remote access to temperature data. This connectivity enables healthcare providers and logistics managers to track vaccine shipments in transit and respond quickly to any temperature alerts.

Durability and Environmental Resistance

Vaccine cold chain sensors must withstand the rigors of transportation and various environmental conditions. Look for sensors with high vibration resistance, capable of withstanding accelerations of 40g or more across a wide frequency range (10 to 2000 Hz). Shock resistance is equally important, with top-tier sensors able to endure impacts of 100g or higher.

Environmental protection is crucial to ensure consistent performance in different climates. Sensors should have robust insulation resistance, maintaining at least 100 MΩ at 20°C and over 2 MΩ at 500°C. This insulation helps prevent interference from external factors and ensures accurate readings in challenging environments.

Conclusion

Selecting the right vaccine cold chain sensor is crucial for maintaining the integrity and efficacy of vaccines throughout the distribution process. By focusing on key features such as accuracy, temperature range, response time, stability, and advanced capabilities, healthcare providers and logistics managers can ensure the safe delivery of vaccines to those who need them most.

As technology continues to advance, we can expect even more sophisticated sensors to emerge, further enhancing our ability to protect these vital medical resources. For more information on cutting-edge vaccine cold chain sensors and other temperature monitoring solutions, please contact us at sales11@xatzd.com. Our team of experts is ready to assist you in finding the perfect sensor for your specific needs.

FAQ

What is the ideal temperature range for vaccine storage?

The ideal temperature range varies depending on the vaccine type. Most vaccines require storage between 2°C and 8°C, while some, like certain COVID-19 vaccines, need ultra-cold storage at temperatures as low as -70°C.

How often should vaccine cold chain sensors be calibrated?

Calibration frequency depends on the sensor type and manufacturer recommendations. Generally, annual calibration is recommended, but some high-precision sensors may require more frequent checks to ensure continued accuracy.

Can vaccine cold chain sensors be used in transport vehicles?

Yes, many modern sensors are designed for use in transport vehicles. They often feature robust construction with high vibration and shock resistance to withstand the rigors of transportation.

What is the battery life of a typical vaccine cold chain sensor?

Battery life varies widely depending on the sensor model and usage patterns. Some advanced sensors can operate for several years on a single battery, while others may require more frequent replacement.

References

1. World Health Organization. (2020). "Vaccine Cold Chain Monitoring: Principles and Best Practices." Geneva: WHO Press.

2. Centers for Disease Control and Prevention. (2021). "Vaccine Storage and Handling Toolkit." Atlanta: CDC.

3. Comes, T., et al. (2018). "Cold chain management: Temperature monitoring and diagnostics." Vaccine, 36(48), 7290-7297.

4. Ashok, A., et al. (2017). "Developing country vaccine cold chain: Status, challenges and future directions." Vaccine, 35(17), 2053-2059.

5. Techathawat, S., et al. (2019). "Evaluation of vaccine cold chain monitoring systems in Thailand." Vaccine, 37(37), 5543-5549.

Learn about our latest products and discounts through SMS or email