- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

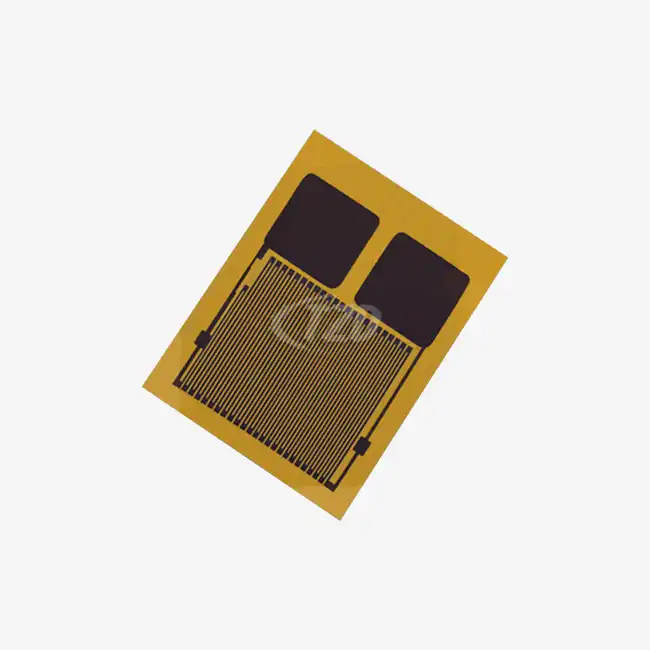

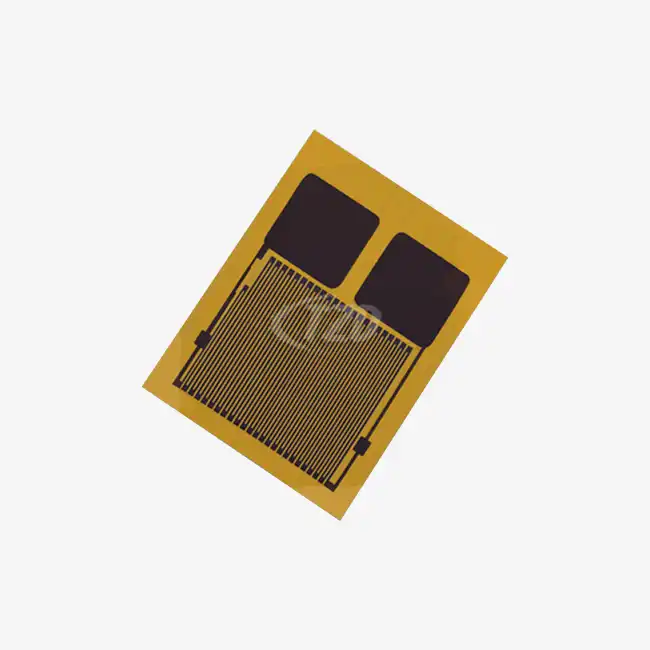

Pt500 RTD Chip

Element Dimensions:2.0mm x 2.3mm x 1.0mm

Lead Specifications:Length: 10 mm,Diameter: 0.2 mm

Lead Material: Platinum-nickel wire (optional: silver-palladium/platinum/pure silver)

Lead Tensile Strength:≥9 N

Insulation Resistance:100 MΩ at 20°C, >2 MΩ at 500°C

Temperature Coefficient (TCR):3850 ppm/°C

Operating Current:0.1–0.7 mA (self-heating effect to be considered)

Long-Term Stability:≤±0.04% resistance drift of R₀ (0°C reference) after 1000 hours at 500°C

Response Time:Watr Flow (V=0.4 m/s):t₀.₅ = 0.05 s,t₀.₉ = 0.15 s;Airflow (V=2 m/s):t₀.₅ = 3 s,t₀.₉ = 10 s

Self-Heating Coefficient:0.4°C/mW (at 0°C)

Vibration Resistance:≥40g acceleration (frequency range: 10–2000 Hz)

Shock Resistance:≥100g acceleration (8 ms half-sine wave)

Packaging:Vacuum plastic packaging (other packaging formats available upon request)

Pt500 RTD Chip Manufacturer And Supplier

Xi'an Tongzida Technology Co., Ltd. is a trusted Pt500 RTD Chip manufacturer and supplier, specializing in high-performance thin-film platinum sensors. Our chips deliver IEC 60751 compliance, 3850 ppm/°C TCR, and exceptional stability for aerospace, medical, automotive, and industrial automation. With ISO 9001, RoHS, and CE certifications, we combine cutting-edge R&D with scalable production to meet global standards.

Why Choose Our Pt500 RTD Chip?

- Ultra-Fast Response: Achieve 0.05s t₀.₅ in liquid flow for real-time monitoring.

- Robust Build: Withstand 40g vibration and 100g shock in harsh environments.

- Wide Range: Operate from -200°C to +850°C with ±0.01Ω accuracy (1/30B Class).

- Customizable: Tailor lead materials (platinum-nickel, pure platinum) and sizes (1.2–4.0mm).

- Longevity: ≤0.04% drift after 1,000 hours at 5°C ensures reduced recalibration costs.

Pt500 RTD Chip Specifications

| Parameter | Value |

|---|---|

| Dimensions | 2.0mm x 2.3mm x 1.0mm |

| Lead Material Options | Platinum-nickel, Silver-palladium, Pure platinum |

| Temperature Coefficient | 3850 ppm/°C (IEC 60751 compliant) |

| Response Time (Liquid) | t₀.₅ = 0.05s; t₀.₉ = 0.15s |

| Insulation Resistance | 100 MΩ at 20°C; >2 MΩ at 500°C |

| Shock Resistance | 100g (8 ms half-sine wave) |

Reference Selection Guide

| Application | Recommended Configuration |

|---|---|

| Automotive Engine Monitoring | 3.0mm chip, platinum-nickel leads, vacuum packaging |

| Medical Sterilization | 2.0mm chip, pure platinum leads, Class A tolerance |

| Aerospace Avionics | 4.0mm chip, silver-palladium leads, anti-vibration coating |

Key Features of Our Thin-Film Platinum Sensor

- Self-Heating Control: 0.4°C/mW coefficient minimizes measurement interference.

- Flexible Integration: Compatible with PLCs, IoT platforms, and legacy systems.

- Vacuum-Sealed Durability: Optional packaging prevents moisture/contaminant ingress.

- Multi-Industry Compliance: Meets ASTM E1137, ATEX, and RoHS directives.

Where Our Pt500 RTD Chip Excels

- Industrial Automation: Monitor turbine temps with vibration-resistant chips.

- EV Battery Management: Track thermal runaway risks in real time.

- HVAC Systems: Optimize energy use with stable, low-drift sensors.

- Patient Monitoring: Ensure ±0.01Ω accuracy for critical diagnostics.

Certifications & Quality Assurance

Every single Pt500 RTD chip in our production line undergoes comprehensive testing in strict accordance with ISO/IEC 17025 standards. This rigorous testing process ensures the accuracy, reliability, and consistency of each chip, verifying its performance across a wide range of conditions. Our commitment to quality is further underscored by multiple certifications. We hold ISO 9001 certification, which attests to our robust quality management system. The CE mark indicates compliance with European health, safety, and environmental protection regulations, while RoHS certification confirms that our products are free from hazardous substances. These certifications together provide a guarantee of the highest quality and safety standards for our products.

Packaging & Delivery

Our standard packaging features vacuum-sealed plastic trays, designed to create an airtight barrier that protects your products from moisture, dust, and contaminants during transit. For bulk orders, we go the extra mile by providing specialized moisture-proof ESD (Electrostatic Discharge) packaging. This advanced packaging not only safeguards against humidity but also prevents damage caused by electrostatic charges, ensuring the integrity of sensitive components. When it comes to custom orders, we understand the need for precision and careful preparation. That's why our lead time ranges from 2–4 weeks, allowing us to meticulously tailor the products and packaging to your specific requirements while maintaining the highest quality standards.

FAQs

Q: Can you provide Class AA tolerance chips?

A: Yes! We offer custom calibration down to ±0.03°C.

Q: Do you support 4-wire configurations?

A: Absolutely. Specify lead count in your RFQ.

Q: What's the MOQ for OEM designs?

A: No strict MOQ – we scale from prototypes to 100k+ batches.

Q: How do you ensure lead durability?

A: Platinum-nickel wires are stress-tested to ≥9N tensile strength.

Q: Are your chips compatible with IoT systems?

A: Yes – output signals integrate seamlessly with most data loggers.

Elevate Your Temperature Measurement Today!

Need a reliable Pt500 RTD Chip partner? Let's customize solutions for your project.

📧 Contact: sales11@xatzd.com

Learn about our latest products and discounts through SMS or email