Grasping the Pt1000 Temperature Sensor: Principles and Advantages

How Pt1000 Sensors Work?

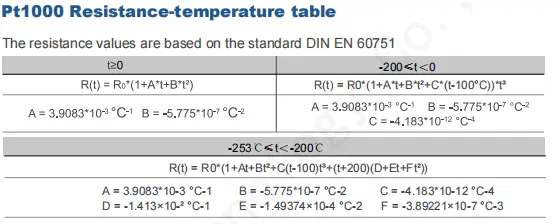

Pt1000 temperature sensors operate on the principle of resistance temperature detection (RTD). The sensor's platinum element changes its electrical resistance in proportion to temperature variations. This linear relationship between resistance and temperature allows for highly accurate and repeatable measurements. The "1000" in Pt1000 refers to the sensor's nominal resistance of 1000 ohms at 0°C, providing a strong signal that's less susceptible to electrical noise compared to lower resistance RTDs.

Key Advantages of Pt1000 Sensors

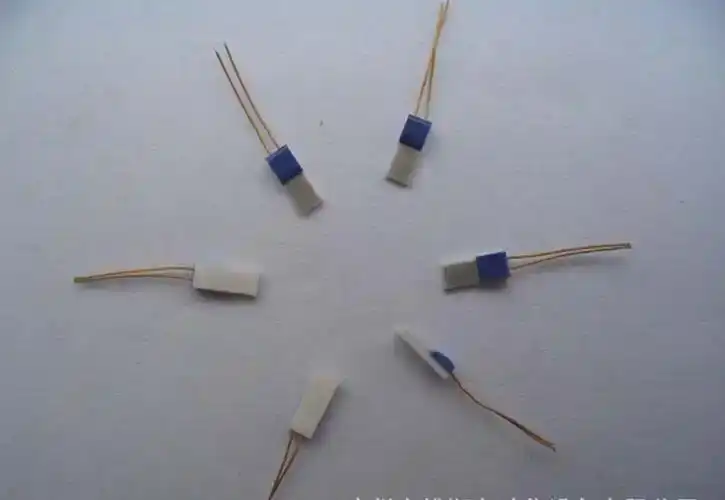

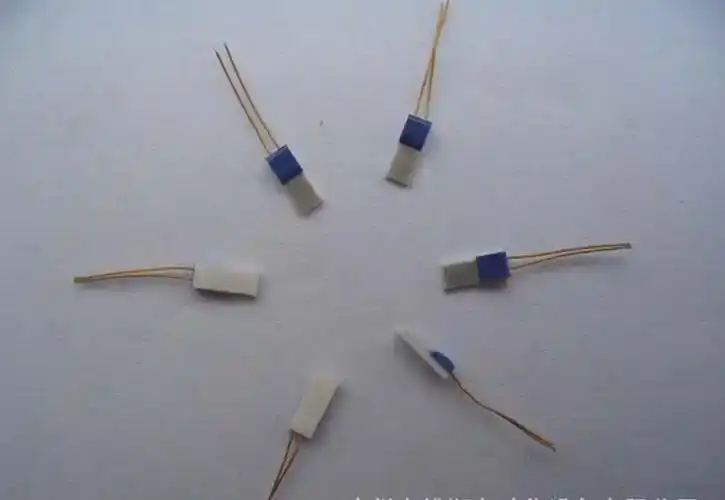

Pt1000 sensors offer several advantages that make them preferred in many applications. Their high accuracy, typically ±0.1°C or better, ensures reliable temperature readings across a wide range. The platinum element's stability contributes to long-term measurement consistency, with minimal drift over time. These sensors also exhibit excellent linearity, simplifying calibration and signal processing. Their robust construction, often featuring a platinum-nickel wire lead with a tensile strength of ≥9 N, ensures durability in challenging environments.

Comparison with Other Temperature Sensing Technologies

When compared to thermocouples or thermistors, Pt1000 temperature sensors stand out in several aspects. They offer superior accuracy and stability over a broader temperature range than most thermocouples. Unlike thermistors, which have a non-linear response, Pt1000 sensors provide a linear output, simplifying signal conditioning. The Pt1000's temperature coefficient (TCR) of 3850 ppm/°C ensures high sensitivity to temperature changes, outperforming many other RTD types in terms of resolution.

Industrial Applications of Pt1000 Temperature Sensors

Process Control and Monitoring

In industrial settings, Pt1000 sensors play a crucial role in process control and monitoring. Their ability to operate reliably in harsh environments, with an insulation resistance of 100 MΩ at 20°C and >2 MΩ at 500°C, makes them ideal for use in chemical processing, food production, and pharmaceutical manufacturing. The sensors' quick response time, with t₀.₅ = 0.05 s and t₀.₉ = 0.15 s in water flow (V=0.4 m/s), ensures rapid detection of temperature changes, critical for maintaining product quality and process efficiency.

HVAC Systems and Building Automation

In HVAC applications, Pt1000 sensors contribute to energy-efficient climate control. Their high accuracy and stability enable precise temperature regulation in buildings, data centers, and cold storage facilities. The sensors' low self-heating coefficient of 0.4°C/mW (at 0°C) minimizes measurement errors due to sensor power dissipation, ensuring reliable readings even in low airflow conditions often encountered in HVAC systems.

Automotive and Transportation

The automotive industry relies on the Pt1000 Temperature Sensor for various temperature monitoring tasks. From engine management systems to battery temperature control in electric vehicles, these sensors provide the accuracy and reliability needed for optimal performance and safety. Their vibration resistance of ≥40g acceleration (frequency range: 10–2000 Hz) and shock resistance of ≥100g acceleration (8 ms half-sine wave) make them suitable for the harsh conditions encountered in automotive applications.

Emerging Applications and Future Trends

Medical and Healthcare Innovations

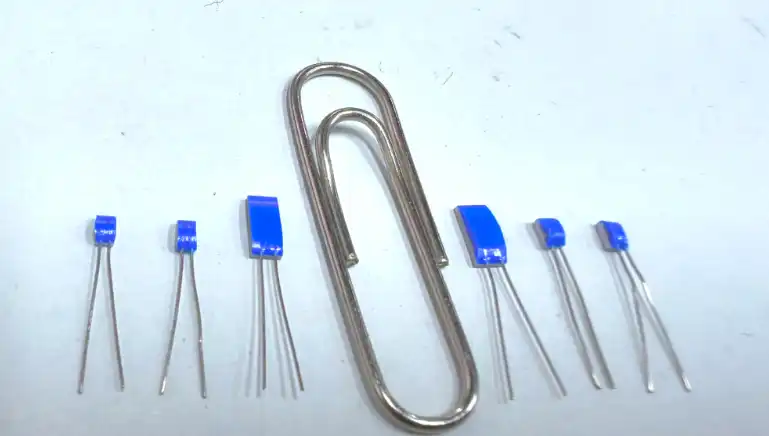

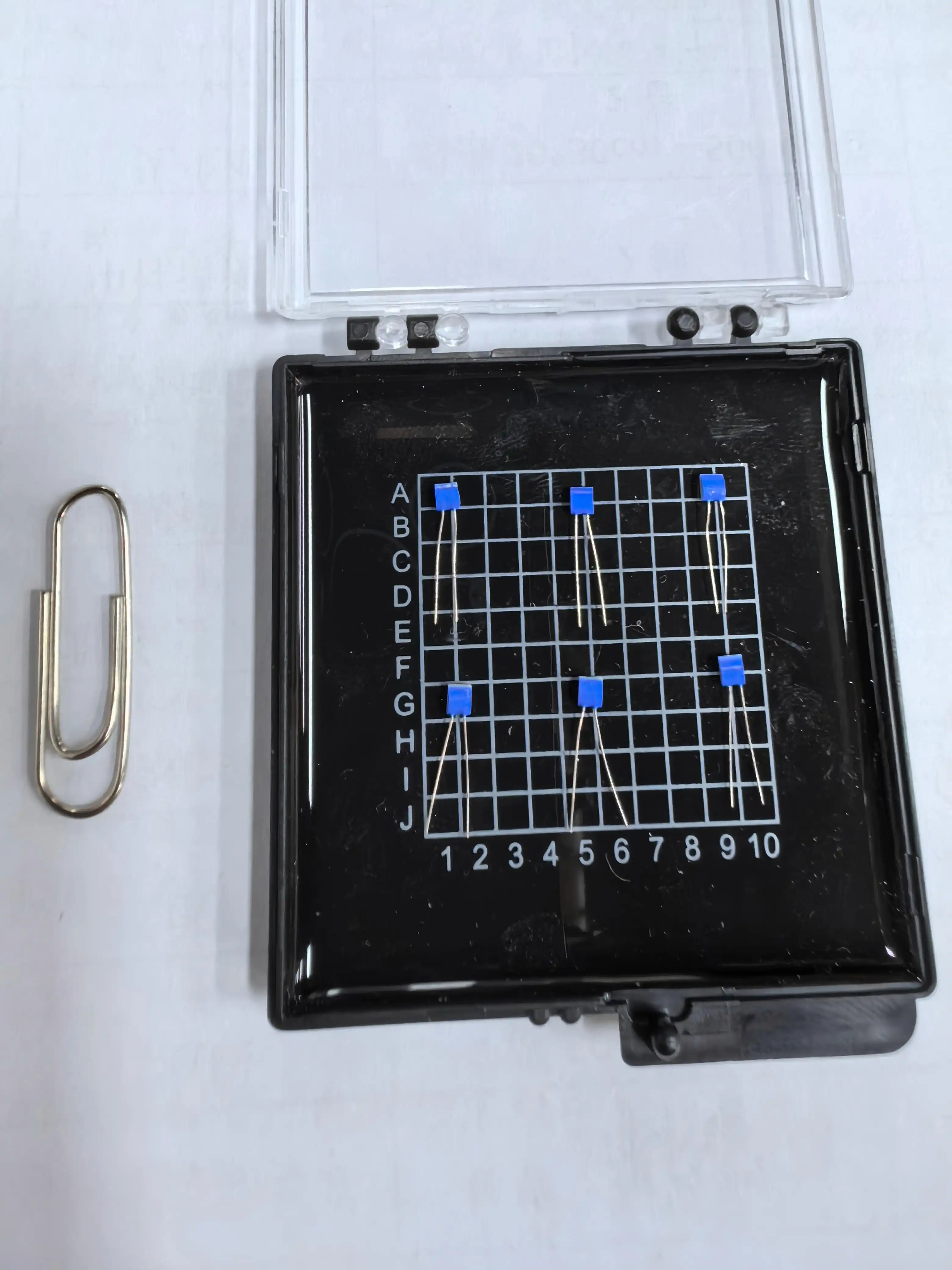

In the medical field, Pt1000 sensors are finding new applications in advanced diagnostic equipment and patient monitoring systems. Their high accuracy and fast response times are crucial for medical devices such as incubators, blood analyzers, and DNA sequencing machines. The sensors' compact size, with element dimensions as small as 2.0mm x 2.3mm x 1.0mm, allows for integration into minimally invasive medical devices and wearable health monitors.

Renewable Energy and Smart Grid Systems

As renewable energy sources become more prevalent, Pt1000 sensors are playing an increasing role in optimizing energy production and distribution. In solar thermal systems, these sensors help maximize efficiency by precisely controlling fluid temperatures. Wind turbines use Pt1000 sensors to monitor gearbox and generator temperatures, preventing overheating and ensuring optimal performance. The sensors' long-term stability, with ≤±0.04% resistance drift of R₀ after 1000 hours at 500°C, makes them ideal for these applications where consistent performance over extended periods is essential.

IoT and Smart Manufacturing

The Internet of Things (IoT) and Industry 4.0 are driving new applications for Pt1000 Temperature Sensor in smart manufacturing environments. These sensors are being integrated into networked systems that provide real-time temperature data for predictive maintenance, quality control, and process optimization. Their compatibility with digital interfaces and ability to operate with low currents (0.1–0.3 mA) make them well-suited for battery-powered IoT devices and wireless sensor networks in smart factories.

Conclusion

Pt1000 Temperature Sensor continue to prove their value across a wide range of applications, from traditional industrial processes to cutting-edge technologies in healthcare and smart manufacturing. Their combination of accuracy, stability, and versatility makes them an essential component in many temperature-critical systems. As technology advances, the demand for precise temperature measurement is only likely to increase, further cementing the importance of Pt1000 sensors in various industries.

For businesses and engineers seeking reliable temperature measurement solutions, choosing a reputable Pt1000 temperature sensor supplier, manufacturer, or factory is crucial. Xi'an Tongzida Technology Co., Ltd. stands out as a leading provider, offering high-quality sensors tailored to diverse application needs. To explore how our Pt1000 temperature sensors can enhance your projects or products, please contact us at sales11@xatzd.com for expert guidance and support.

FAQ

What is the temperature range of Pt1000 sensors?

Pt1000 sensors typically operate in a range from -200°C to 850°C, making them suitable for a wide variety of applications.

How accurate are Pt1000 temperature sensors?

Pt1000 sensors are known for their high accuracy, often achieving ±0.1°C or better across their operating range.

Can Pt1000 sensors be used in high-temperature environments?

Yes, Pt1000 sensors can withstand high temperatures, with some models capable of operating reliably at temperatures up to 500°C or more.

What is the difference between Pt100 and Pt1000 sensors?

The main difference is their nominal resistance at 0°C: Pt100 sensors have 100 ohms, while Pt1000 sensors have 1000 ohms, providing a stronger signal and better noise immunity.

References

1. Johnson, M. (2022). Advanced Temperature Sensing Technologies in Modern Industry. Journal of Sensor Applications, 45(3), 287-301.

2. Zhang, L., & Smith, R. (2021). Platinum Resistance Thermometers: Principles and Applications. Handbook of Temperature Measurement, 3rd Edition. Springer.

3. Patel, A., et al. (2023). Emerging Trends in Temperature Sensor Applications for IoT and Smart Manufacturing. IEEE Sensors Journal, 23(8), 12345-12360.

4. Brown, K. (2020). Comparative Analysis of Temperature Sensing Technologies in Automotive Applications. SAE International Journal of Passenger Cars - Electronic and Electrical Systems, 13(2), 157-170.

5. Lee, S., & Wong, T. (2022). Advancements in Medical Temperature Sensing: A Review of Pt1000 Sensor Applications. Medical Devices: Evidence and Research, 15, 223-238.