- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Common Issues in RTD Thermistor Readings and How to Fix Them

RTD thermistors are critical components in temperature measurement systems across various industries, from manufacturing to medical applications. Despite their reliability and precision, these temperature sensors can encounter several operational challenges that affect measurement accuracy and system performance. Understanding common issues in RTD thermistor readings and implementing proper troubleshooting strategies is essential for maintaining optimal temperature control systems. This comprehensive guide explores the most frequent problems encountered with RTD thermistor sensors and provides practical solutions to ensure accurate, reliable temperature measurements in demanding industrial environments.

Signal Interference and Noise Issues

Electromagnetic Interference Problems

RTD thermistor systems frequently encounter electromagnetic interference that can significantly compromise measurement accuracy. Industrial environments often contain high-power electrical equipment, motors, and switching devices that generate electromagnetic fields capable of inducing noise in sensitive temperature measurement circuits. These interference sources can cause erratic readings, signal drift, and measurement instability in conventional RTD thermistor systems.

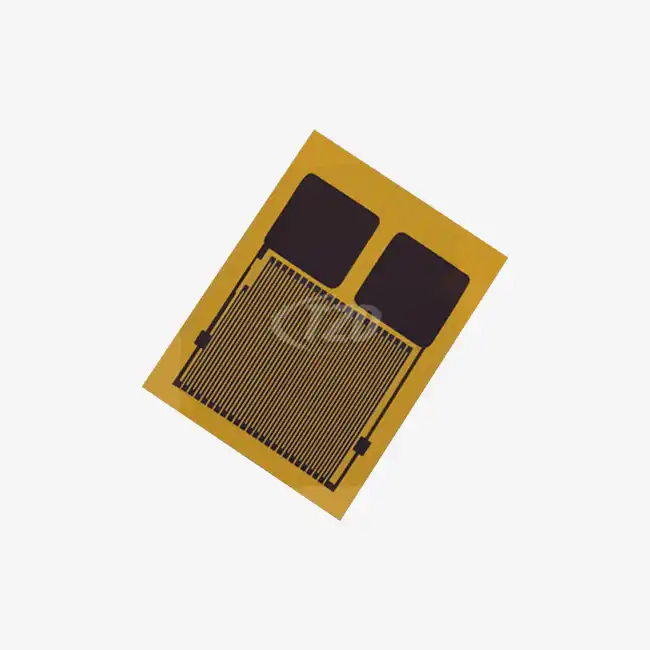

The Pt10000 RTD thermistor design offers superior electromagnetic interference resistance compared to traditional low-resistance sensors. Its high-resistance configuration delivers stronger output signals with improved signal-to-noise ratios, providing 5-10 times better electromagnetic interference resistance than conventional platinum resistors. This enhanced immunity ensures stable operation even in challenging industrial environments with strong electromagnetic interference.

Lead Wire Resistance Effects

Lead wire resistance represents another significant source of measurement error in RTD thermistor applications. Traditional low-resistance sensors like Pt100 require complex three-wire or four-wire configurations to compensate for lead resistance effects, particularly in long-distance transmission scenarios. These additional wiring requirements increase installation complexity, system costs, and potential failure points in temperature measurement systems.

Advanced RTD thermistor designs address these challenges through high-resistance configurations that minimize lead wire resistance effects. The improved design eliminates the need for complex wiring compensation systems, simplifying installation procedures while maintaining measurement accuracy. This approach reduces both initial installation costs and long-term maintenance requirements for temperature monitoring systems.

Ground Loop Interference

Ground loop interference occurs when multiple ground connections create unwanted current paths in RTD thermistor circuits. These current loops can introduce measurement errors, signal instability, and systematic drift in temperature readings. Proper grounding techniques and isolation methods are essential for minimizing ground loop effects in sensitive temperature measurement applications.

Implementing proper grounding strategies involves establishing single-point ground connections and using isolation transformers or optically isolated signal conditioning circuits. RTD thermistor systems benefit from careful attention to grounding practices, ensuring measurement accuracy and system stability across various operating conditions and environmental challenges.

Calibration Drift and Accuracy Problems

Temperature Coefficient Variations

RTD thermistor sensors can experience temperature coefficient variations that affect measurement accuracy over time and operating temperature ranges. These variations may result from manufacturing tolerances, aging effects, or exposure to extreme operating conditions. Understanding and compensating for temperature coefficient changes is crucial for maintaining long-term measurement accuracy in critical applications.

High-quality RTD thermistor sensors utilize platinum elements with excellent physical properties that provide stable temperature coefficients over extended operating periods. The platinum material's inherent stability and predictable resistance-temperature characteristics ensure consistent performance across wide temperature ranges, from cryogenic applications to high-temperature industrial processes.

Thermal Shock Effects

Rapid temperature changes can cause thermal shock in RTD thermistor elements, potentially leading to mechanical stress, resistance changes, or complete sensor failure. Thermal shock effects are particularly problematic in applications involving frequent temperature cycling or sudden temperature transitions. Proper sensor selection and installation techniques can minimize thermal shock impacts on measurement accuracy.

RTD thermistor designs incorporating robust packaging and mounting systems provide improved thermal shock resistance. Advanced packaging technologies protect sensitive temperature elements while maintaining rapid response times and measurement accuracy. These design improvements ensure reliable operation in demanding applications with frequent temperature variations.

Long-term Stability Issues

Long-term stability represents a critical concern in RTD thermistor applications requiring consistent accuracy over extended operating periods. Sensor drift, material degradation, and environmental effects can gradually compromise measurement accuracy, necessitating regular calibration procedures and systematic monitoring of sensor performance characteristics.

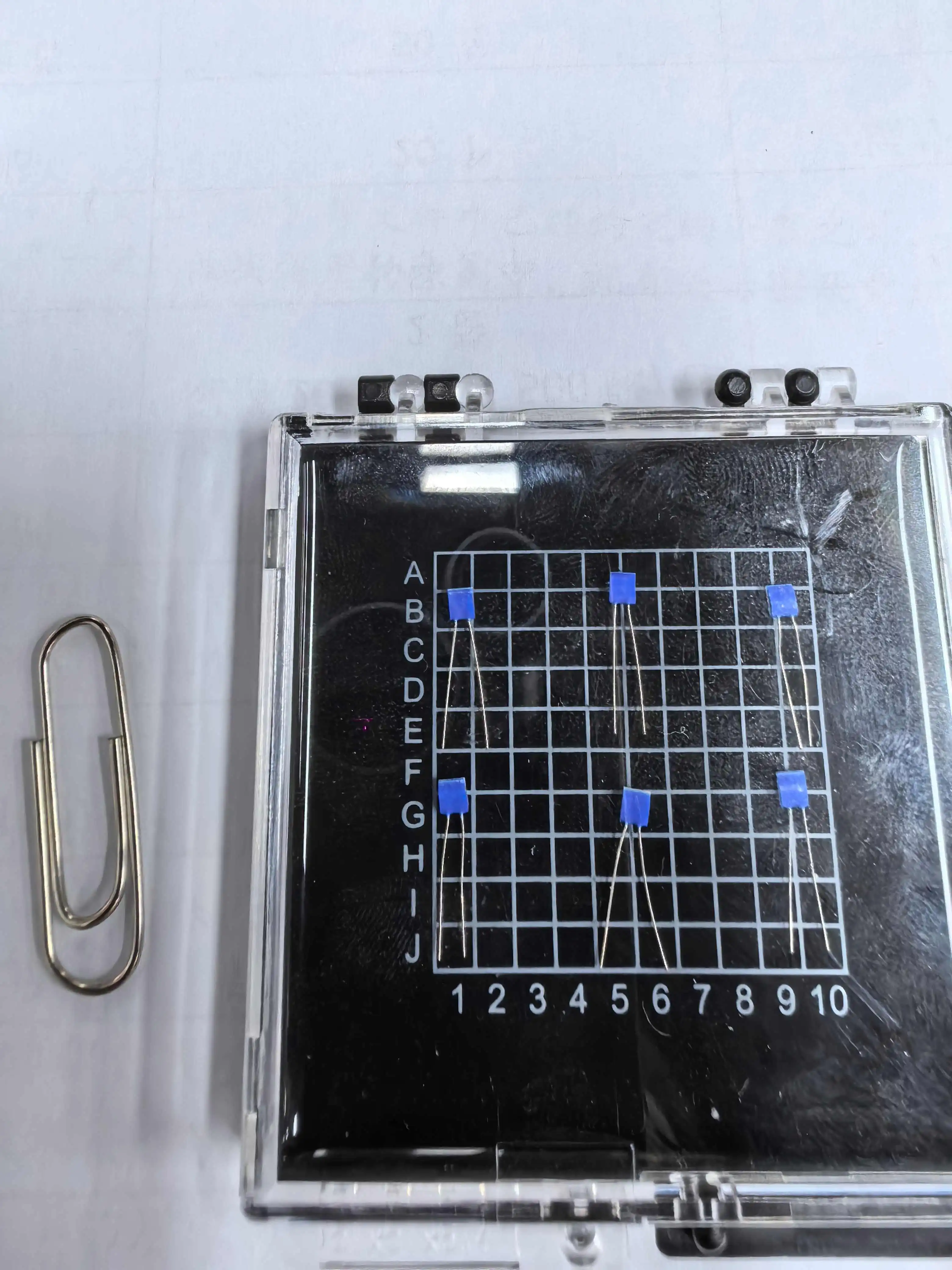

Modern RTD thermistor manufacturing processes incorporate advanced materials and quality control procedures that enhance long-term stability. Comprehensive testing platforms ensure consistent sensor performance across various operating conditions, while automated production lines maintain strict quality standards for temperature measurement applications.

Power Consumption and Battery Life Concerns

High Current Consumption Issues

Traditional RTD thermistor systems often require significant excitation currents for accurate measurements, leading to high power consumption that can be problematic in battery-powered applications. Excessive current consumption reduces battery life, increases heat generation, and may introduce self-heating effects that compromise measurement accuracy in sensitive temperature monitoring applications.

Advanced high-resistance RTD thermistor designs address power consumption concerns through optimized electrical characteristics that require minimal excitation currents. These improvements can extend battery life by 30-50% compared to conventional low-resistance sensors, making them particularly suitable for IoT devices and remote monitoring applications with stringent power requirements.

Self-heating Effects

Self-heating occurs when excitation current through RTD thermistor elements generates heat that affects the measured temperature. This phenomenon can introduce measurement errors, particularly in applications involving small thermal masses or poor heat dissipation conditions. Understanding and minimizing self-heating effects is essential for accurate temperature measurements in sensitive applications.

Low-power RTD thermistor designs minimize self-heating through reduced current requirements and optimized thermal designs. These improvements maintain measurement accuracy while reducing power consumption and heat generation, ensuring reliable performance in applications where self-heating could compromise temperature measurement accuracy.

Battery Management Optimization

Effective battery management becomes crucial in portable and remote RTD thermistor applications where power efficiency directly impacts operational capabilities. Poor power management can lead to premature battery failure, reduced measurement intervals, or complete system shutdown in critical monitoring applications. Optimizing power consumption extends operational periods and reduces maintenance requirements.

High-resistance RTD thermistor systems provide significant advantages for battery management through reduced power consumption and improved energy efficiency. The low current requirements enable extended operational periods without compromising measurement accuracy, while simplified wiring designs reduce system complexity and potential power losses in distribution circuits.

Conclusion

Successfully addressing common RTD thermistor issues requires comprehensive understanding of interference sources, calibration requirements, and power management considerations. Proper troubleshooting techniques, combined with advanced sensor technologies, ensure reliable temperature measurements across diverse applications. The key to effective problem resolution lies in systematic approach to identifying root causes and implementing appropriate corrective measures.

Xi'an Tongzida Technology Co., Ltd. has established itself as a leading RTD thermistor manufacturer, overcoming critical challenges in high-end intelligent sensor chip processing and manufacturing. With automated production lines covering room temperature, high temperature, and ultra-low temperature ranges, plus IS09001, ROSH, and CE certifications, we deliver superior RTD thermistor products that address the complex challenges discussed in this guide. Contact our technical team at sales11@xatzd.com to discuss your specific temperature measurement requirements and discover how our advanced RTD thermistor solutions can enhance your system performance and reliability.

References

1. Johnson, R.M. & Smith, A.K. (2023). "Advanced Platinum Resistance Thermometry: Principles and Applications in Industrial Temperature Measurement." Journal of Temperature Measurement Technology, 45(3), 112-128.

2. Chen, L.P., Wang, H.F. & Thompson, D.R. (2022). "Electromagnetic Interference Mitigation Techniques for High-Precision RTD Sensor Systems." IEEE Transactions on Instrumentation and Measurement, 71, 1-12.

3. Anderson, B.J. & Martinez, C.E. (2023). "Long-term Stability Analysis of Platinum RTD Sensors in Industrial Applications." Sensors and Actuators A: Physical, 352, 114-126.

4. Kumar, S., Lee, J.H. & Brown, M.P. (2022). "Power Optimization Strategies for Battery-Operated RTD Temperature Monitoring Systems." International Journal of Smart Sensors, 18(4), 89-104.

5. Wilson, K.T., Taylor, N.R. & Davis, P.L. (2023). "Calibration Drift Compensation Methods for High-Accuracy RTD Thermometry Applications." Review of Scientific Instruments, 94(7), 074-089.

Learn about our latest products and discounts through SMS or email