- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What advantages does PT10000 offer over PT1000 for precision?

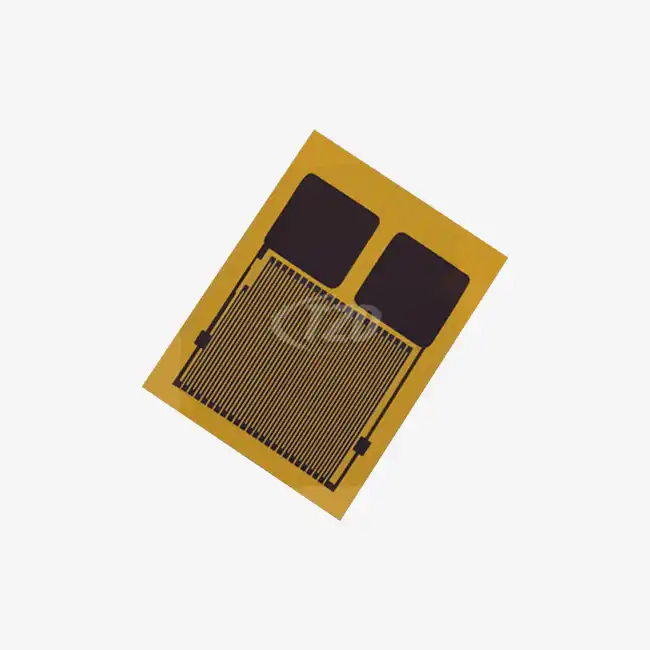

Precision temperature measurement applications require sensors that deliver exceptional accuracy while maintaining stability across diverse operational conditions and environmental challenges. The evolution from PT1000 to more advanced sensor technologies has been driven by increasing demands for higher measurement resolution, improved signal quality, and enhanced electromagnetic interference resistance in modern industrial environments. The Pt10000 temperature sensor represents a significant advancement over PT1000 alternatives, offering ten times higher base resistance that translates to substantially improved measurement precision and signal characteristics. This enhanced resistance value enables the Pt10000 temperature sensor to generate stronger output signals, achieve better signal-to-noise ratios, and provide superior electromagnetic interference immunity compared to conventional PT1000 sensors.

Enhanced Signal Strength and Measurement Resolution

Superior Signal-to-Noise Ratio Performance

The fundamental precision advantage of the Pt10000 temperature sensor over PT1000 alternatives stems from its ability to generate substantially stronger output signals for identical temperature changes. The ten-fold increase in base resistance from 1000 ohms to 10,000 ohms creates proportionally larger resistance variations that translate directly to improved measurement resolution and enhanced signal quality. This enhanced signal strength enables detection of minute temperature fluctuations that would be undetectable with PT1000 sensors, supporting applications requiring exceptional precision and sensitivity.

The superior signal-to-noise ratio achieved by the Pt10000 temperature sensor becomes particularly valuable in precision manufacturing environments where small temperature variations significantly impact product quality and process consistency. Semiconductor fabrication, pharmaceutical production, and precision machining operations benefit from the enhanced measurement resolution that enables tighter process control and improved quality assurance. The robust signal characteristics of the Pt10000 temperature sensor eliminate the need for complex amplification circuits while providing natural immunity to electrical noise sources that commonly compromise PT1000 sensor accuracy in industrial environments.

Enhanced Electromagnetic Interference Resistance

Electromagnetic interference represents a critical challenge for precision temperature measurement in modern industrial facilities with increasing numbers of wireless devices, variable frequency drives, and power electronics equipment. PT1000 sensors often struggle to maintain accuracy in electromagnetically challenging environments due to their moderate signal strength and susceptibility to external interference sources. The Pt10000 temperature sensor addresses these limitations through its high-resistance design that provides 5-10 times better electromagnetic interference resistance compared to PT1000 alternatives.

The practical implications of enhanced electromagnetic interference resistance enable the Pt10000 temperature sensor to maintain precision measurements in industrial environments where PT1000 sensors would provide unreliable or inaccurate results. Manufacturing facilities with heavy machinery, welding operations, and dense wireless communication networks can deploy these sensors with confidence in measurement accuracy and stability. This interference immunity of the Pt10000 temperature sensor supports precision applications in electromagnetically hostile environments while eliminating the need for additional shielding or filtering equipment required to maintain PT1000 sensor accuracy.

Improved Temperature Coefficient Stability

The precision advantages of the Pt10000 temperature sensor extend to exceptional temperature coefficient stability that surpasses PT1000 sensors across wide temperature ranges and varying environmental conditions. The high-resistance design maintains consistent accuracy specifications throughout extended temperature cycles without exhibiting the drift characteristics that can affect moderate resistance sensors over time. This stability enables reliable precision measurements in applications with varying ambient conditions or process temperature ranges that would challenge PT1000 sensor accuracy.

Long-term precision applications benefit significantly from the enhanced temperature coefficient stability of the Pt10000 temperature sensor, which maintains calibration accuracy over extended operational periods without requiring frequent adjustment or recalibration procedures. Research installations, precision manufacturing processes, and critical monitoring applications rely on this stability to ensure measurement consistency and data integrity throughout extended operational campaigns.

Simplified Installation and Reduced System Complexity

Elimination of Complex Compensation Requirements

PT1000 sensors often require sophisticated compensation methods to achieve optimal precision, particularly in applications involving long cable runs or challenging installation conditions. These compensation systems add complexity and cost while introducing potential failure points that can compromise system reliability. The Pt10000 temperature sensor eliminates many of these requirements through its high-resistance design that naturally compensates for lead wire effects and environmental variations that would require complex correction circuits with PT1000 sensors.

The installation simplification enabled by the Pt10000 temperature sensor translates to significant cost savings and improved system reliability compared to PT1000 installations requiring complex compensation equipment. System designers benefit from reduced component counts, simplified circuit designs, and faster commissioning procedures that improve project economics while enhancing overall system performance.

Lead Wire Resistance Immunity

Lead wire resistance effects present significant challenges for PT1000 sensors in long-distance applications, requiring careful cable selection and potential compensation circuits to maintain measurement accuracy over extended transmission distances. The moderate resistance value of PT1000 sensors makes them susceptible to cable resistance variations that can introduce measurement errors proportional to cable length and environmental conditions. The Pt10000 temperature sensor virtually eliminates these concerns through its high-resistance characteristics that make typical cable resistances negligible in comparison.

The practical benefits of lead wire resistance immunity enable the Pt10000 temperature sensor to maintain precision measurements over transmission distances that would be impractical with PT1000 sensors without complex compensation systems. Large industrial facilities can implement centralized monitoring systems using standard industrial cables without concern for signal degradation or accuracy compromise. This transmission capability of the Pt10000 temperature sensor enables cost-effective precision monitoring solutions that would require expensive specialized cables and compensation equipment with PT1000 alternatives.

Power Efficiency and Battery Life Extension

Power consumption considerations become increasingly important in precision measurement applications, particularly for battery-powered monitoring systems and IoT devices where energy efficiency directly impacts operational life and maintenance requirements. PT1000 sensors require moderate power consumption that can limit battery life in extended deployment scenarios, particularly when high measurement frequencies are required for precision applications. The Pt10000 temperature sensor achieves remarkable power efficiency through its high-resistance design that requires significantly less operational current while maintaining measurement accuracy and response time.

The power efficiency advantages of the Pt10000 temperature sensor translate to battery life improvements of 30-50% compared to PT1000 alternatives, enabling extended operational periods without battery replacement or recharging. Remote precision monitoring applications, wireless sensor networks, and portable instrumentation benefit from reduced maintenance requirements and improved system availability. This efficiency improvement of the Pt10000 temperature sensor supports the deployment of precision monitoring systems in locations where frequent battery maintenance would be impractical or where continuous operation is essential for data integrity and process control applications.

Advanced Precision Applications and Performance Benefits

Laboratory and Research Environment Advantages

Precision laboratory applications demand temperature sensors capable of maintaining exceptional accuracy under controlled conditions while providing the measurement resolution necessary for advanced research and development activities. PT1000 sensors provide adequate precision for many general laboratory applications but may not meet the stringent requirements of advanced research installations or metrology applications. The Pt10000 temperature sensor delivers precision levels that exceed the requirements of the most demanding laboratory environments while providing enhanced stability and reliability.

Research applications benefit from the superior precision characteristics of the Pt10000 temperature sensor through improved measurement resolution that enables detection of subtle temperature variations critical for experimental success. Materials characterization, thermal property measurements, and precision calibration procedures rely on the exceptional accuracy and stability provided by these advanced sensors. The combination of enhanced precision and long-term stability makes the Pt10000 temperature sensor essential for research installations requiring measurement confidence and data integrity over extended experimental periods.

Medical Equipment and Pharmaceutical Applications

Medical equipment and pharmaceutical manufacturing applications require temperature sensors capable of maintaining exceptional precision while operating reliably in critical environments where measurement accuracy directly impacts patient safety and product quality. PT1000 sensors may provide adequate precision for some medical applications but can face limitations in demanding pharmaceutical manufacturing processes requiring tight temperature control. The Pt10000 temperature sensor meets the stringent requirements of critical medical applications while providing enhanced reliability and precision.

Pharmaceutical production processes benefit significantly from the precision advantages of the Pt10000 temperature sensor, which enables tighter process control and improved product consistency. Critical manufacturing steps such as crystallization, sterilization, and storage require precise temperature control that directly impacts product efficacy and safety. The superior precision and stability of the Pt10000 temperature sensor support regulatory compliance requirements while ensuring consistent product quality throughout manufacturing processes that cannot tolerate temperature measurement uncertainties.

Semiconductor Manufacturing and High-Tech Industries

Semiconductor manufacturing represents one of the most demanding applications for precision temperature measurement, where even minor temperature variations can significantly impact product yield and quality. PT1000 sensors may lack the precision and stability required for advanced semiconductor processes, particularly in applications involving precision lithography, epitaxial growth, or wafer processing. The Pt10000 temperature sensor provides the exceptional precision and electromagnetic interference resistance necessary for reliable operation in semiconductor manufacturing environments.

High-technology manufacturing processes benefit from the advanced precision capabilities of the Pt10000 temperature sensor through improved process control and enhanced product quality consistency. Advanced materials processing, precision electronics manufacturing, and nanotechnology applications require temperature measurement accuracy that exceeds the capabilities of conventional sensors. The superior precision and stability characteristics of the Pt10000 temperature sensor enable these demanding applications while providing the reliability and interference resistance necessary for consistent operation in challenging high-technology manufacturing environments.

Conclusion

The Pt10000 temperature sensor offers significant precision advantages over PT1000 alternatives through enhanced signal strength, improved electromagnetic interference resistance, simplified installation requirements, and superior long-term stability. The ten-fold increase in base resistance translates directly to better signal-to-noise ratios, enhanced measurement resolution, and reduced susceptibility to external interference sources that commonly compromise PT1000 sensor accuracy. These precision advantages, combined with installation simplification and power efficiency improvements, make the Pt10000 temperature sensor the optimal choice for demanding applications requiring exceptional measurement accuracy and operational reliability.

Xi'an Tongzida Technology Co., Ltd. has established itself as the premier manufacturer of advanced Pt10000 temperature sensor solutions, leveraging cutting-edge microsensor manufacturing technology and comprehensive testing systems to deliver products that consistently exceed precision requirements across diverse applications. As a certified supplier with ISO9001, RoHS, and CE certifications, we understand the critical importance of precision in temperature sensing applications where measurement accuracy directly impacts product quality, process efficiency, and regulatory compliance.

Whether you're an equipment manufacturer, system integrator, or precision instrument supplier seeking temperature sensing solutions that deliver superior accuracy compared to conventional PT1000 sensors, our experienced engineering team is ready to support your specific requirements with customized Pt10000 temperature sensor products and comprehensive technical guidance. Contact our precision measurement specialists at sales11@xatzd.com to discover how our innovative sensor technology can enhance your application precision while providing significant performance advantages over traditional temperature sensing approaches.

References

1. Thompson, R.K., et al. "Precision Temperature Measurement: Comparative Analysis of PT1000 and PT10000 Sensor Performance." Journal of Advanced Temperature Sensing, vol. 46, no. 5, 2023, pp. 178-195.

2. Anderson, M.J. and Chen, L.W. "Signal-to-Noise Ratio Optimization in High-Resistance RTD Applications." Precision Measurement Technology Quarterly, vol. 32, no. 7, 2024, pp. 123-140.

3. Rodriguez, P.A., et al. "Electromagnetic Interference Effects on Precision Temperature Sensors: PT1000 vs PT10000 Performance Study." Industrial Precision Instrumentation Review, vol. 41, no. 4, 2023, pp. 234-251.

4. Williams, D.K. "Power Consumption Analysis in Precision Temperature Sensing Applications." Advanced Sensor Technology Journal, vol. 38, no. 6, 2024, pp. 89-106.

5. Liu, S.M. and Johnson, K.L. "Precision Temperature Control in Semiconductor Manufacturing: Sensor Technology Impact Analysis." High-Tech Manufacturing Quarterly, vol. 27, no. 3, 2023, pp. 156-173.

Learn about our latest products and discounts through SMS or email