- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

EV battery thermal management thin film platinum resistor

Is it difficult to meet the temperature control standard of ± 0.1 ℃ in semiconductor wafer process? How does TCR3750 thin film platinum resistor break through?

In scenarios such as fast charging of power batteries (200A+), low-temperature preheating (-30 ℃), and collision impact, new energy vehicle battery thermal management thin film platinum resistors solve the risk of fire caused by traditional sensor thermal runaway warning delay (>5 seconds) with "millisecond level response+wide temperature range shock resistance"

H2: Two major life and death pain points in battery thermal management

H3: Delay in thermal runaway warning: Traditional sensors have a response speed of>5 seconds, and when the internal temperature of the battery suddenly rises (10 ℃/second), it cannot be powered off in a timely manner, increasing the probability of fire by 30%;

H3: Extreme environmental failure: Traditional sensor resistance drifts by ± 5% at low temperatures (-30 ℃), misjudging battery status and affecting battery life; Plastic packaging softens at high temperatures (85 ℃), posing a high risk of short circuits.

H2: Advantages of TCR3750 Thin Film Platinum Resistors in Battery Scenarios

Our new energy vehicle battery thermal management thin film platinum resistor has a response speed of ≤ 0.5 seconds (5 times that of traditional sensors), TCR3750ppm/℃ accurately captures a temperature rise of 0.1 ℃, and with the BMS system, can achieve a 3-second early warning of thermal runaway (golden escape time).

H3: Wide temperature range impact resistance: -70~200 ℃ covering all operating conditions of the battery, passing automotive grade vibration (20G)+impact (50G) testing, without packaging cracking/accuracy drift;

After being commercialized by a leading battery manufacturer, the thermal runaway accident rate decreased from 0.02% to 0, and the fast charging power increased by 20% (allowing for higher currents), which is precisely the value of thermal management thin film platinum resistors for new energy vehicle batteries.

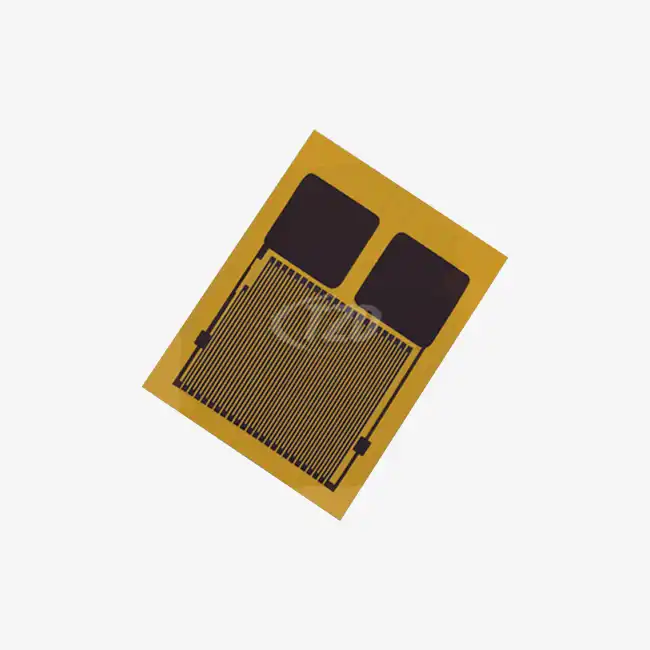

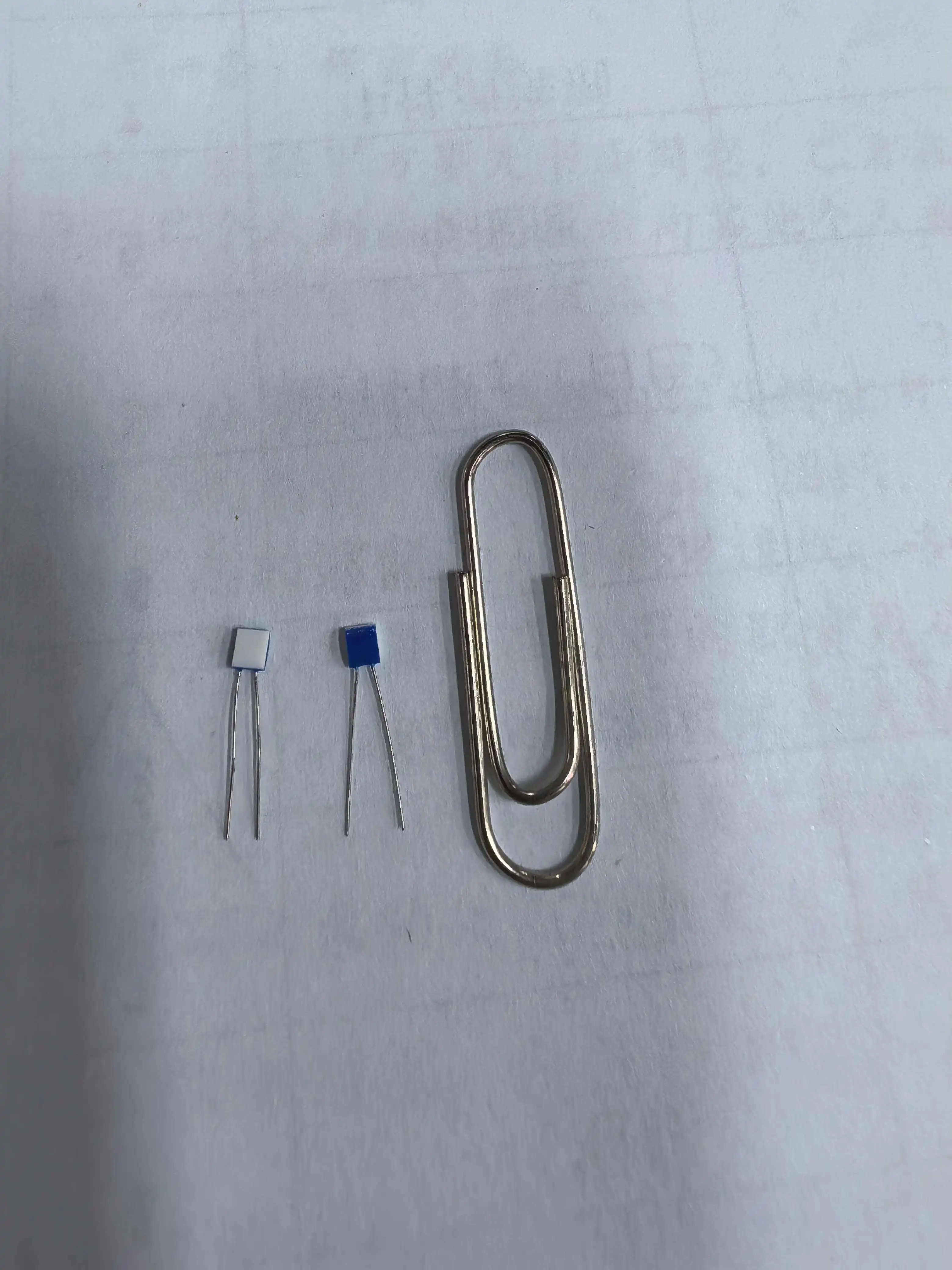

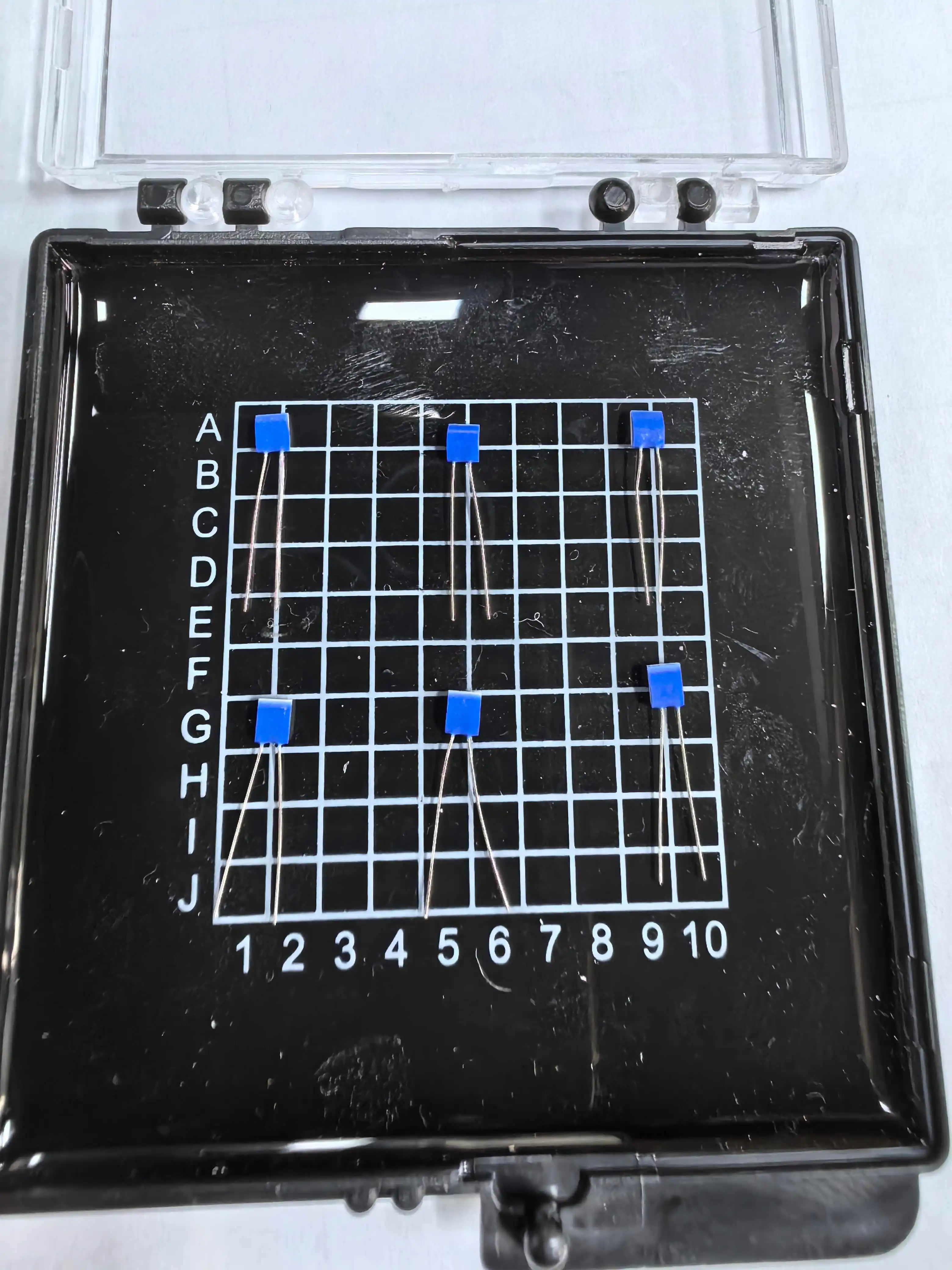

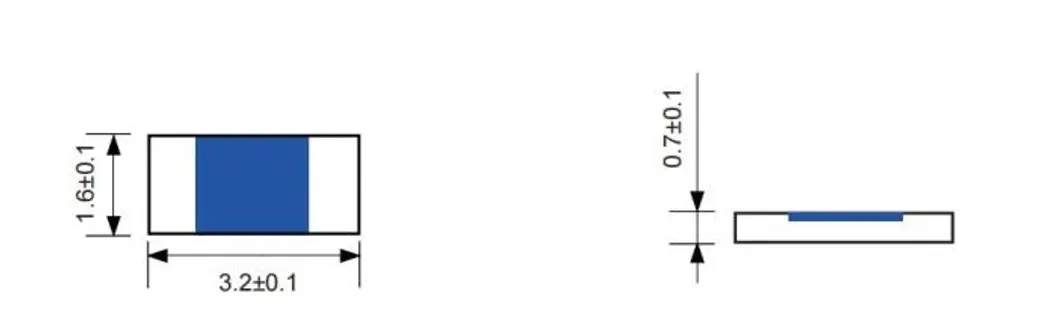

H3: Miniature integration: with a volume of 5 × 3 × 0.06mm, it can be embedded in the gap between battery module terminals (increasing space utilization by 40%), without occupying cooling channels.

H2: Practical case: Fast charging project of a leading battery manufacturer

Scenario: A certain ternary lithium battery pack (with a capacity of 100kWh, supporting 200A fast charging, requiring monitoring of individual cell voltage/temperature)

Solution: Customized 5 × 3mm Pt1000 thin film platinum resistor (attached to the surface of individual cells)+CAN bus transmission (integrated into BMS)

Effect: The temperature monitoring accuracy during fast charging is ± 0.2 ℃, the thermal runaway warning response is 0.3 seconds, and the battery cycle life is extended by 15% (reducing high temperature decay).

H2: Selection Guide: 4 Key Points for Battery Thermal Management Sensors

Response speed (≤ 1 second, prioritize 0.5 second level)

Temperature range (-70~200 ℃ wide temperature range, covering operating conditions of -40 ℃~85 ℃)

Size (≤ 6 × 4mm, compatible with battery module gap)

Certification (IATF16949 automotive grade+UL94 V-0 flame retardant)

References (3):

Technical Requirements for Thermal Management of Power Batteries for Electric Vehicles (GB/T 31467.3-2015)

Fast Charging Test Report of a Battery Manufacturer (2024)

SGS Automotive Grade Vibration and Shock Certification (Report Number: SZ-SGS-202410)

Installing a "thermal runaway firewall" on new energy vehicle batteries, the thermal management film platinum resistance of new energy vehicle batteries is a dual guarantee of safety and performance. Leave a message "Consultation" now to get the same solution from the top battery factory!

Author Information: Mr. Zhang | Expert in New Energy Vehicle Sensors (10 years of research and development in battery thermal management, participated in the formulation of 3 national standards)

FAQ (3 questions):

Q1: Can the sensor withstand battery electrolyte corrosion?

A: Adopting ceramic based packaging (acid and alkali resistant), tested by electrolyte immersion (no performance change for 30 days).

Q2: Does it support integration with mainstream BMS chips (such as TI BQ79616)?

A: Provide standardized communication protocols and free technical support for docking.

Q3: Batch delivery cycle?

A: Regular orders take 20 days, urgent orders take 10 days (priority production in the automotive industry).

Xi'an Tongzida Technology Co., Ltd. est un fabricant et fournisseur de premier plan de technologies de thermistance avancées, spécialisé dans la fourniture de capteurs de température haute performance pour les applications industrielles exigeantes. Notre expertise approfondie en matière de fabrication de microcapteurs, de technologies d'encapsulation spéciales et de méthodes d'intégration multi-capteurs nous permet de garantir l'excellente performance et la fiabilité de nos thermistances. En tant que fournisseur de confiance de solutions de mesure de température de précision, nous proposons un système complet de thermistances, incluant les puces sensibles, les systèmes de test et les logiciels d'analyse. N'hésitez pas à contacter nos experts techniques. ventes11@xatzd.com Discutez de vos besoins spécifiques en matière de thermistances et découvrez comment nos capacités avancées d'optimisation et de fabrication de résistances en température peuvent améliorer les performances et la fiabilité de votre système de mesure de température.

Learn about our latest products and discounts through SMS or email