- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

semiconductor equipment temperature control thin film platinum resistor

Is it difficult to meet the temperature control standard of ± 0.1 ℃ in semiconductor wafer process? How does TCR3750 thin film platinum resistor break through?

In the scenarios of temperature control of lithography machine lenses (± 0.1 ℃) and temperature uniformity of etching machine chambers (± 0.5 ℃), semiconductor manufacturing equipment uses temperature controlled thin film platinum resistors with "nano level stability+vacuum compatible packaging" to solve the problem of drift above ± 1 ℃ caused by long-term operation of traditional sensors

H2: Two major technical bottlenecks in temperature control of semiconductor equipment

H3: Long term drift: Traditional sensors experience a resistance drift of ± 2% after 1000 hours in vacuum (10 ⁻⁶ Pa) and high temperature (200 ℃) environments, resulting in a 5% decrease in wafer yield;

H3: Poor vacuum compatibility: Organic packaging materials release gases, polluting lithography machine lenses, and maintenance costs exceed one million yuan per time.

H2: Advantages of TCR3750 Thin Film Platinum Resistors in Semiconductor Scenarios

Our semiconductor manufacturing equipment temperature controlled thin film platinum resistors use metal thin film technology (non organic packaging), with a resistance drift of<± 0.1% after 1000 hours in a vacuum environment. Combined with laser tuning technology, the accuracy reaches ± 0.05 ℃ (the top level in the industry).

H3: Anti electromagnetic interference: The electromagnetic field strength of wafer manufacturing equipment (such as plasma etching machines) is greater than 100V/m, the sensor has passed EMC Class B certification, and the signal has zero interference;

After being used in a certain 12 inch wafer fab, the yield loss caused by temperature drift of the lithography machine decreased from 3% to 0.2%, with an annual efficiency increase of over 20 million yuan. This is precisely the value of temperature controlled thin film platinum resistors in semiconductor manufacturing equipment.

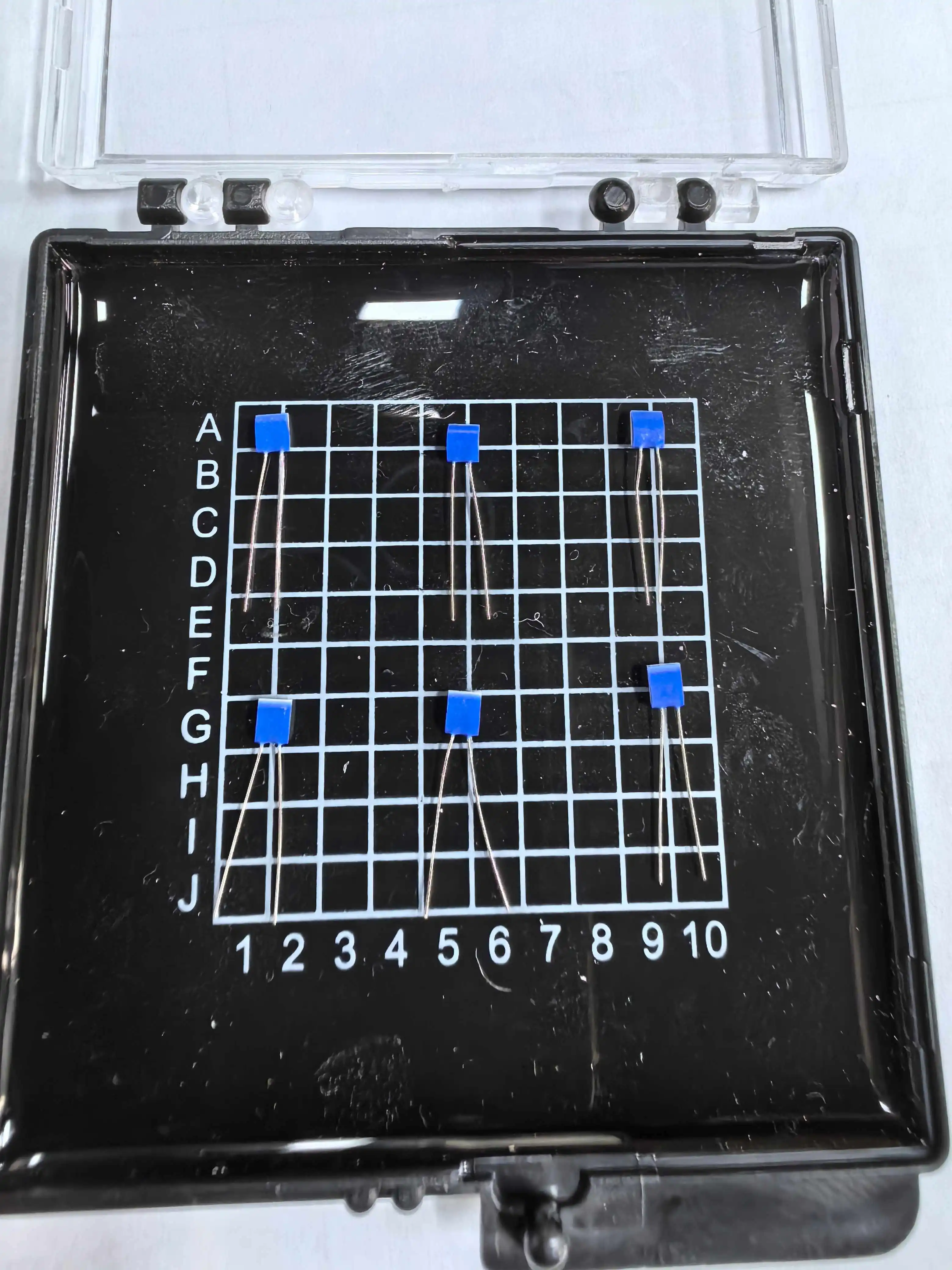

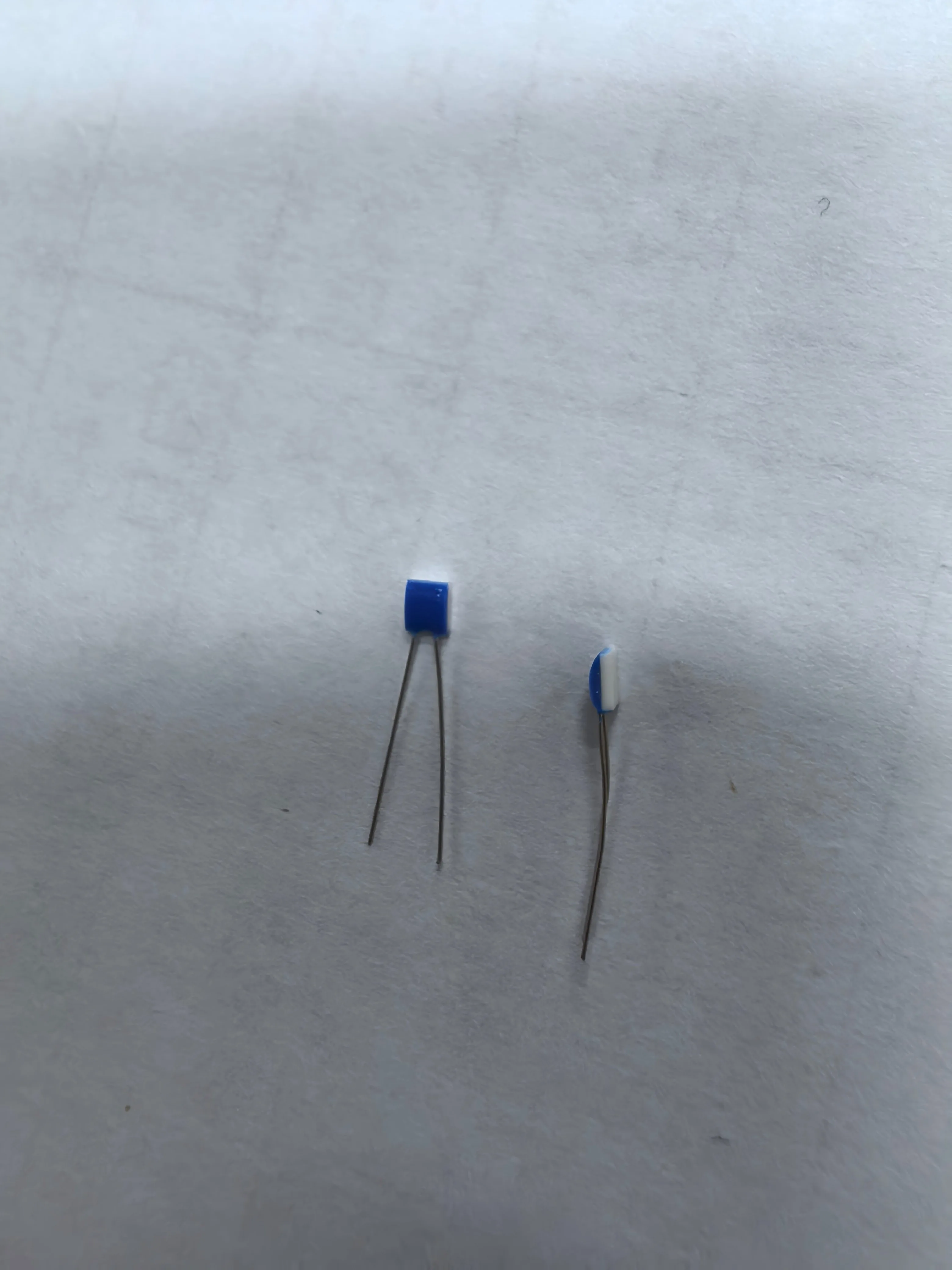

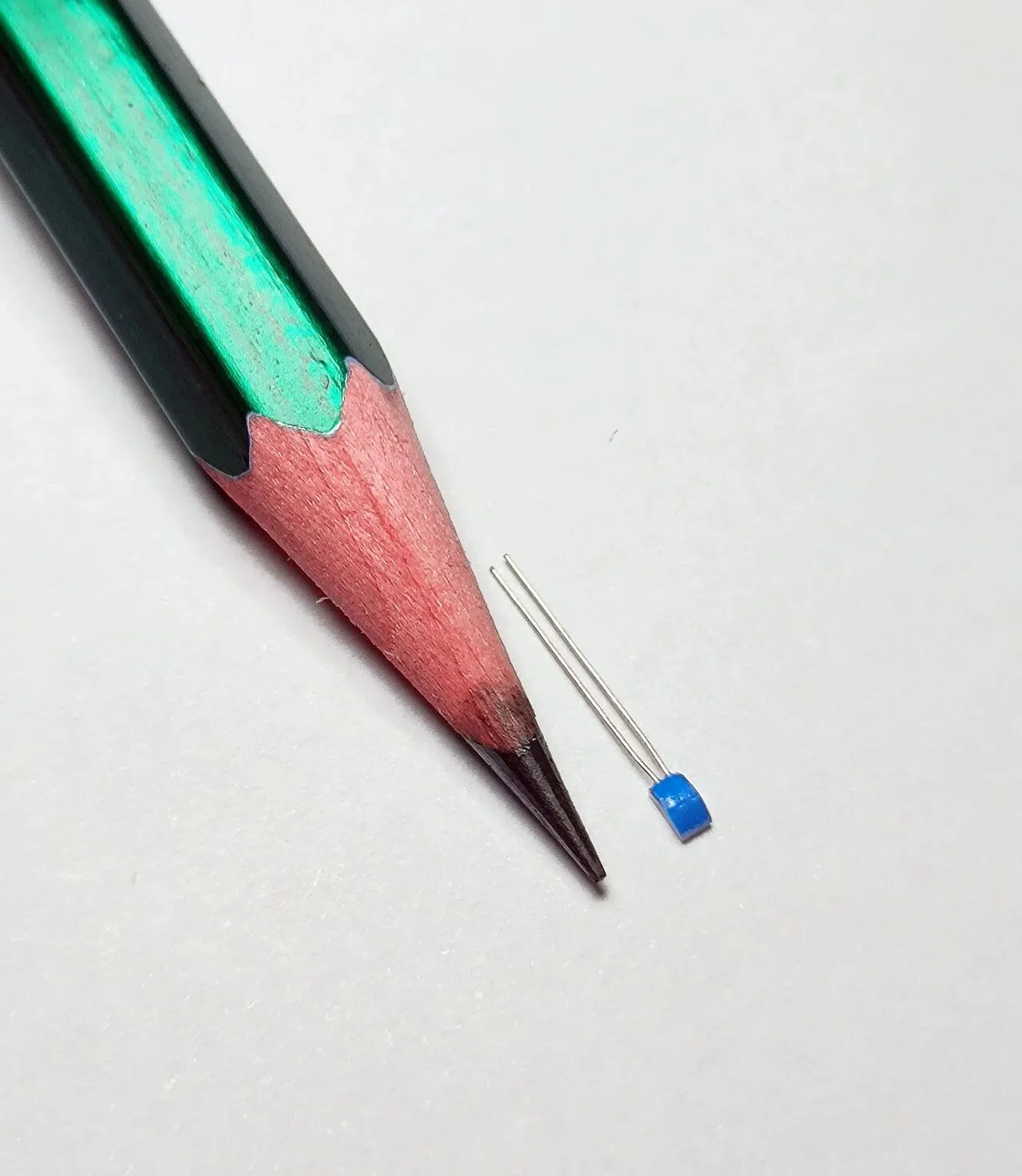

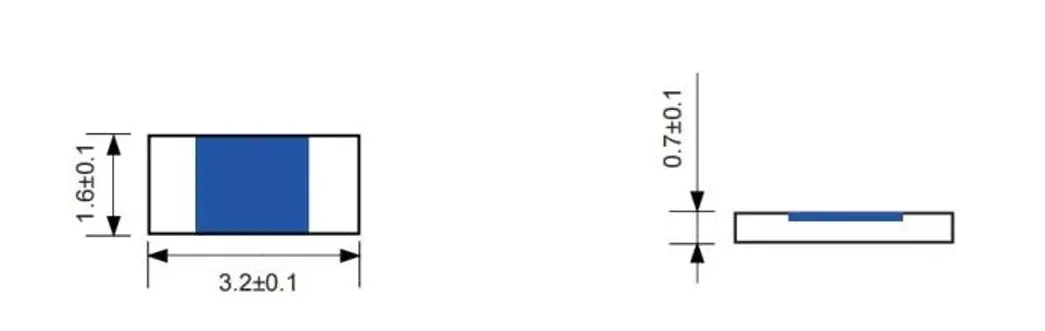

H3: Miniature and highly integrated: with a volume of 3 × 2 × 0.04mm, it can be densely arranged on wafer carriers (spacing<5mm) to monitor temperature uniformity at multiple points.

H2: Practical case: Temperature control upgrade of lithography machine in a 12 inch wafer fab

Scenario: ASML lithography machine from a certain factory (lens temperature control required ± 0.1 ℃, vacuum environment 10 ⁻⁷ Pa, continuous operation for 720 hours)

Solution: Customized 3 × 2mm PT100 thin film platinum resistor (ceramic based packaging, attached to lens holder)+fiber optic transmission (anti electromagnetic interference)

Effect: Temperature control accuracy ± 0.08 ℃, drift<± 0.1% after 3000 hours of continuous operation, lens cleaning cycle extended from 1 month to 6 months.

H2: Selection Guide: Four Core Indicators of Semiconductor Device Sensors

Long term drift (≤± 0.1%/1000h, vacuum environment)

Vacuum compatibility (outgassing rate<1 × 10 ⁻⁹ Torr · L/s)

Accuracy (± 0.05 ℃ level, laser tuning type preferred)

Certification (SEMI Semiconductor Equipment Standard+ISO 9001)

References (3):

Specification for Temperature Control of Semiconductor Manufacturing Equipment (SEMI E15-0309)

Report on the upgrade of lithography machines in a certain wafer fab (2024)

SGS Vacuum Compatibility Test Report (Report No. SH-SGS-202411)

To safeguard the "nanoscale precision" of semiconductor manufacturing, temperature controlled thin film platinum resistors for semiconductor manufacturing equipment are the key to breakthroughs in domestic high-end equipment. Private message communication with technical consultants to obtain the same solution for wafer fabs!

Author Information: Mr. Chen | Director of Semiconductor Sensor R&D (15 years of experience in thermal management of semiconductor equipment, holding 5 patents)

FAQ (3 questions):

Q1: Can the sensor withstand plasma bombardment?

A: Ceramic based packaging+metal shielding layer, tested in a plasma etching machine environment (100 hours without damage).

Q2: Does it support customized tuning (such as specifying resistance values)?

A: Provide laser tuning services with a resistance tolerance of ± 0.01% to meet special process requirements.

Q3: Minimum order quantity?

A: Minimum order of 100 pieces (friendly for small batch verification in the semiconductor industry), supporting customization based on drawings.

Xi'an Tongzida Technology Co., Ltd. est un fabricant et fournisseur de premier plan de technologies de thermistance avancées, spécialisé dans la fourniture de capteurs de température haute performance pour les applications industrielles exigeantes. Notre expertise approfondie en matière de fabrication de microcapteurs, de technologies d'encapsulation spéciales et de méthodes d'intégration multi-capteurs nous permet de garantir l'excellente performance et la fiabilité de nos thermistances. En tant que fournisseur de confiance de solutions de mesure de température de précision, nous proposons un système complet de thermistances, incluant les puces sensibles, les systèmes de test et les logiciels d'analyse. N'hésitez pas à contacter nos experts techniques. ventes11@xatzd.com Discutez de vos besoins spécifiques en matière de thermistances et découvrez comment nos capacités avancées d'optimisation et de fabrication de résistances en température peuvent améliorer les performances et la fiabilité de votre système de mesure de température.

Learn about our latest products and discounts through SMS or email