The Evolution of Flexible Thin Film Temperature Sensors

Flexible thin - film temperature sensors mark a substantial advancement in temperature measurement technology. These sensors combine the precision of traditional thin film sensors with the added benefit of flexibility, opening up new avenues for application and design.

Advancements in Material Science

The advancement of flexible thin film temperature sensors has been largely propelled by breakthroughs in material science. Significant progress has been made in developing conductive polymers and nanomaterials that maintain their electrical properties under bending or stretching. These materials are key to flexible sensors, enabling them to conform to curved shapes or be embedded in fabric-like substrates.

Miniaturization and Improved Performance

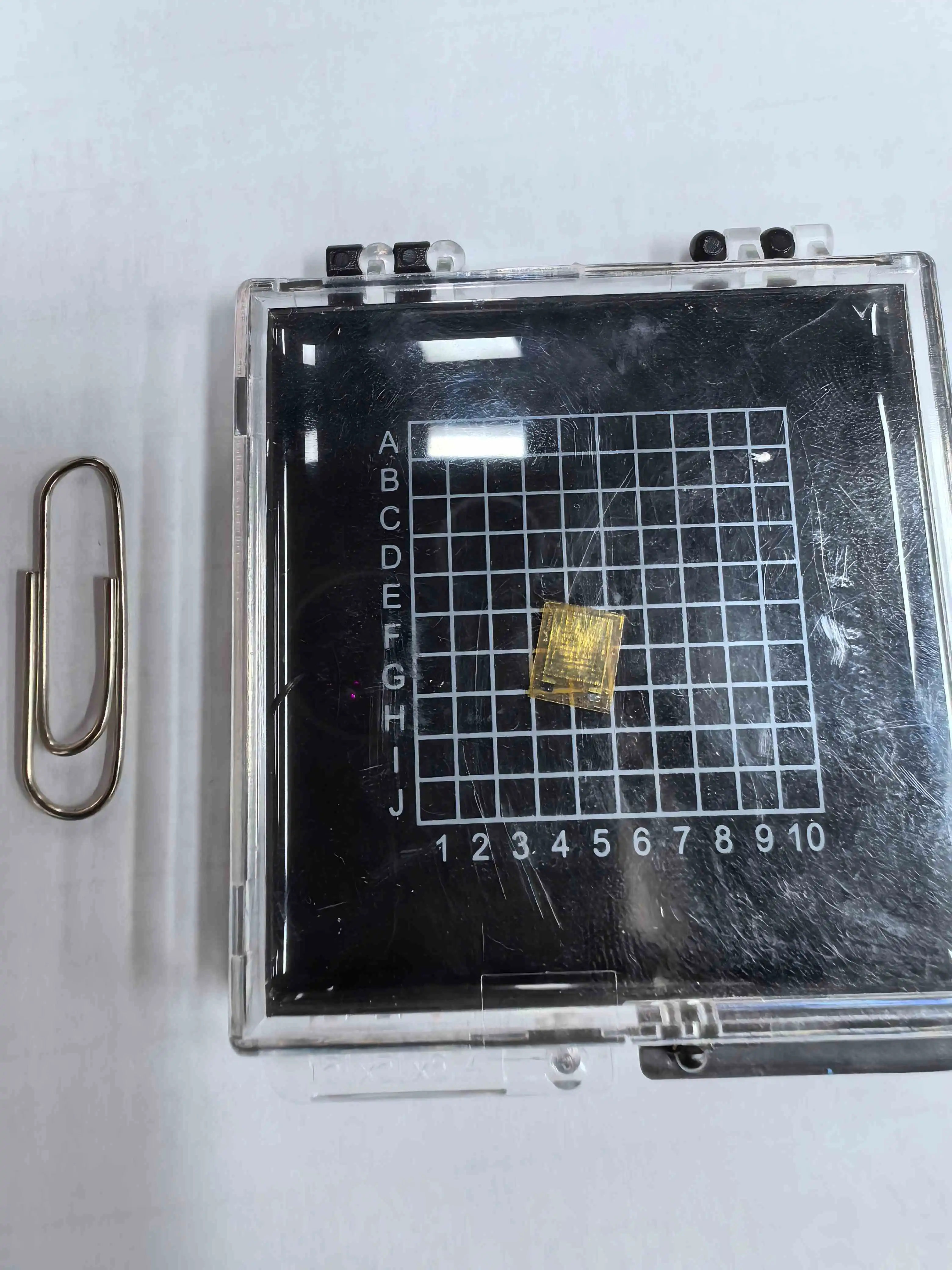

With improvements in manufacturing, flexible thin-film temperature sensors have become much smaller. This smaller size, along with better sensor designs, has improved their performance. Today’s flexible sensors deliver fast response times, high accuracy, and strong long-term reliability. For example, some advanced models respond in as little as 0.05 seconds and achieve accuracy around ±0.01 Ω, making them ideal for tasks that need quick and precise temperature readings.

Expanded Temperature Range and Durability

The latest flexible thin-film temperature sensors have surpassed many of the limits seen in rigid types. They can measure temperatures across a wide span, usually from -200℃ to +850℃, making them suitable for a variety of uses—from very cold cryogenic operations to high-heat industrial settings. Improvements in how these sensors are made have also boosted their toughness, with some models able to handle vibrations up to 40g and shocks up to 100g, providing dependable performance even in demanding conditions.

Applications and Market Demand for Flexible Thin Film Temperature Sensors

Flexible thin film temperature sensors are employed across numerous industries, each leveraging their distinctive features to tackle specific challenges.

Healthcare and Wearable Technology

Flexible thin film temperature sensors are changing how patients are monitored and diagnosed in healthcare. Integrated into wearable devices, they allow constant and non-invasive temperature measurement. This is particularly helpful for tracking fevers, monitoring patients after surgery, or managing chronic conditions that require frequent temperature checks. Their flexible form also makes them comfortable for patients to wear over extended periods.

Automotive and Aerospace Industries

The automotive and aerospace industries have widely adopted flexible thin-film temperature sensors because they can deliver precise temperature readings even in tight and complex spaces. In vehicles, these sensors are important for engine control, managing battery temperatures in electric cars, and regulating climate systems. In aerospace, they monitor essential components to help maintain safety and peak performance. Their durability against strong vibrations and impacts makes them ideal for these tough conditions.

Industrial Process Control and IoT Integration

In industrial settings, flexible thin-film temperature sensors are increasingly used in smart manufacturing. Their ability to conform to various surfaces allows for precise temperature measurement of machines and products. This precision is crucial for quality control in industries such as food processing, chemical manufacturing, and pharmaceuticals. Moreover, these sensors integrate smoothly with IoT platforms, making them popular in smart factories where they support real-time monitoring and predictive maintenance.

Future Outlook and Innovations in Flexible Thin Film Temperature Sensors

The future of flexible thin film temperature sensors appears promising, with continuous research and development efforts focused on further enhancing their capabilities and expanding their applications.

Integration with Advanced Materials

Researchers are working on flexible thin-film temperature sensors that use advanced materials such as graphene and carbon nanotubes. Because of their excellent electrical and thermal features, these materials could help create sensors that measure temperature more accurately and respond more quickly. Incorporating them might also improve the sensors’ durability against environmental factors, allowing for a wider range of applications.

Self-Powered and Wireless Capabilities

The development of self-powered flexible thin film temperature sensors is an area of growing interest. By incorporating energy harvesting technologies, such as thermoelectric or piezoelectric elements, these sensors could operate autonomously, eliminating the need for external power sources. This progress would be especially useful for remote sensing or places where changing batteries often is difficult. Also, adding wireless communication will make these sensors more flexible, allowing easy data transfer and connection with larger IoT networks.

Biocompatible and Biodegradable Sensors

With progress in healthcare and environmental fields, the demand is increasing for sensors that are safe to use in the human body and can naturally break down. Researchers are working on flexible thin-film temperature sensors made from materials that can be safely implanted and naturally break down after use. This could enable important new uses in implantable medical devices and environmental monitoring, especially where recovering the sensors is difficult or not possible.

Conclusion

The global market for flexible thin film temperature sensors is at an exciting juncture, with technological advancements driving new possibilities across various industries. As these sensors continue to evolve, becoming more accurate, durable, and versatile, their adoption is expected to accelerate. The integration of flexible thin film temperature sensors with IoT and AI technologies promises to unlock new levels of efficiency and innovation in fields ranging from healthcare to industrial automation.

For those interested in exploring the cutting-edge developments in thin film temperature sensor technology or seeking customized solutions for specific applications, please contact us at sales11@xatzd.com. Our team of experts is ready to assist you in leveraging these advanced sensors for your unique requirements.