- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Thin Film vs Wire Wound: Which Platinum Resistor Performs Better?

In the realm of temperature sensing, thin film platinum resistors outperform their wire wound counterparts in several key aspects. The thin film platinum resistor Pt20-DW, in particular, showcases superior performance characteristics. With its compact size, rapid response time, and excellent stability, thin film technology offers significant advantages over traditional wire wound designs. These include improved accuracy, faster thermal response, and enhanced durability in demanding environments. While wire wound resistors still have their place in certain applications, thin film platinum resistors are increasingly becoming the go-to choice for precision temperature measurement across various industries.

Introducing Thin Film and Wire Wound Platinum Resistors

The Fundamentals of Platinum Resistance Thermometry

Platinum resistance thermometers (PRTs) are renowned for their accuracy and stability in temperature measurement. These devices exploit the predictable change in electrical resistance of platinum as temperature fluctuates. The relationship between resistance and temperature is nearly linear, making platinum an ideal material for precise temperature sensing.

Wire Wound Platinum Resistors: Traditional but Robust

Wire wound platinum resistors have been the stalwart of temperature measurement for decades. These sensors consist of a fine platinum wire wrapped around a ceramic or glass core. While they offer good stability and can withstand high temperatures, their construction method introduces certain limitations. The coiled wire structure can lead to strain-induced errors and slower response times due to the thermal mass of the assembly.

Thin Film Platinum Resistors: Modern Precision

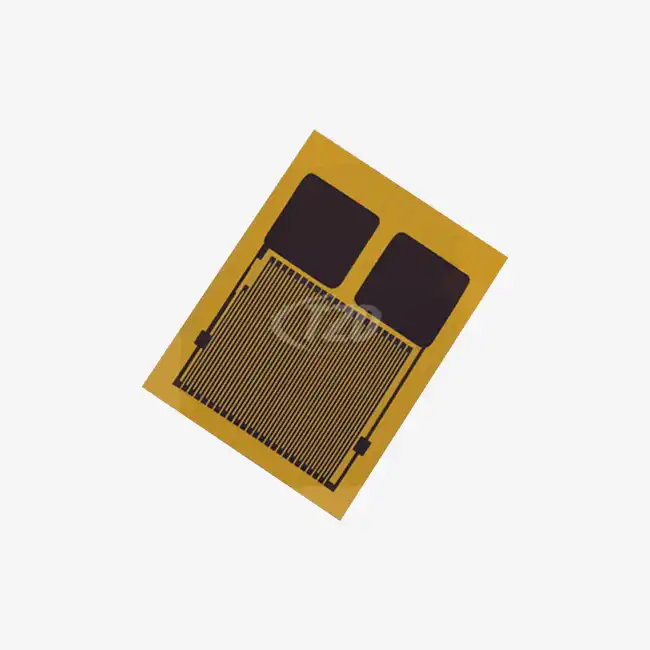

Thin film technology represents a significant advancement in platinum resistance thermometry. The thin film platinum resistor Pt20-DW exemplifies this progress. These sensors are fabricated by depositing a thin layer of platinum onto a ceramic substrate, typically using sputtering or evaporation techniques. This method allows for precise control over the resistor's geometry and properties, resulting in a more compact and responsive sensor.

Comparative Analysis: Thin Film vs Wire Wound Performance

Size and Integration Advantages

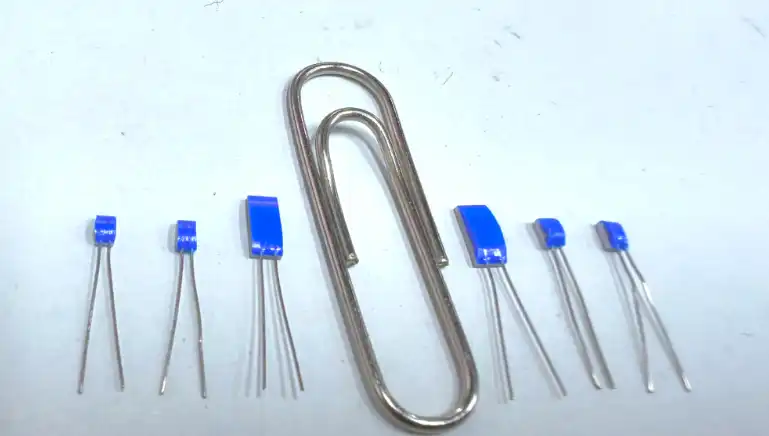

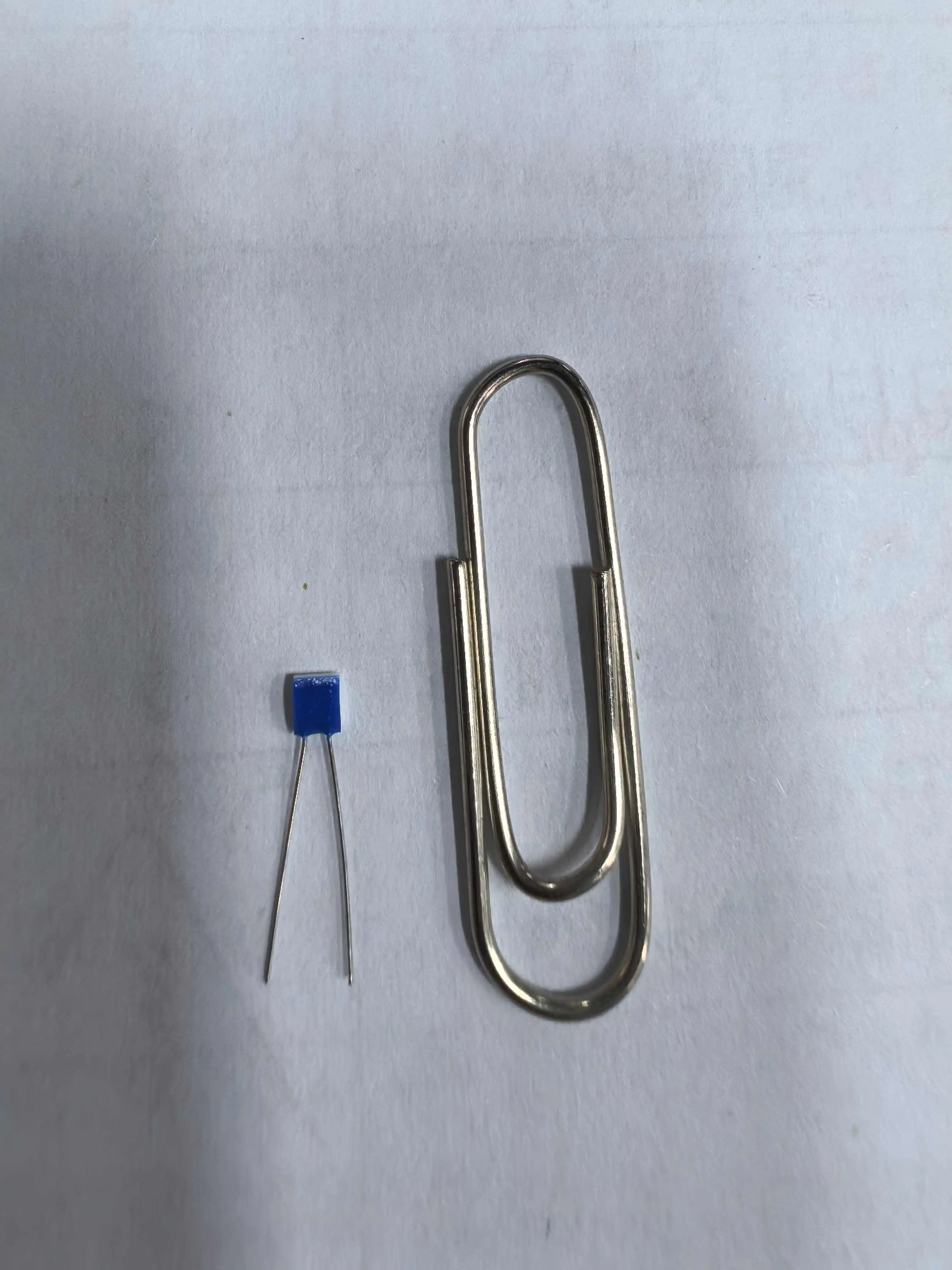

The Thin Film Platinum Resistor Pt20-DW boasts impressive dimensions of just 2.0mm x 2.3mm x 1.0mm. This miniature size offers significant advantages in applications where space is at a premium. In contrast, wire wound resistors are generally bulkier due to their construction method. The compact nature of thin film sensors facilitates easier integration into complex systems and allows for more precise point measurements.

Response Time and Sensitivity

One of the most striking advantages of thin film platinum resistors is their rapid response to temperature changes. The Pt20-DW exhibits remarkable response times: in water flow (V=0.4 m/s), it achieves t₀.₅ = 0.05 s and t₀.₉ = 0.15 s. Even in airflow (V=2 m/s), the response times are impressive at t₀.₅ = 3 s and t₀.₉ = 10 s. This quick reaction is crucial in applications requiring real-time temperature monitoring. Wire wound resistors, with their larger thermal mass, typically have slower response times, which can be a limitation in dynamic temperature environments.

Accuracy and Stability

Thin film platinum resistors offer exceptional accuracy and stability. The thin film platinum resistor Pt20-DW, for instance, adheres to the IEC60751 standard and features a temperature coefficient of 3850 ppm/°C. Its long-term stability is remarkable, with a resistance drift of ≤±0.04% of R₀ (0°C reference) after 1000 hours at 500°C. This level of stability ensures reliable measurements over extended periods, even in harsh conditions. While wire wound resistors can also achieve high accuracy, they are more susceptible to mechanical stresses that can affect their long-term stability.

Applications and Industry Impact of Thin Film Platinum Resistors

Industrial and Scientific Applications

The superior performance characteristics of thin film platinum resistors like the Pt20-DW make them ideal for a wide range of industrial and scientific applications. These sensors excel in environments that demand high precision, such as semiconductor manufacturing, pharmaceutical production, and laboratory research. Their ability to provide accurate measurements across a broad temperature range (-200°C to +850°C) makes them versatile tools in various processes.

Automotive and Aerospace Advancements

In the automotive and aerospace sectors, the compact size and robust nature of thin film platinum resistors offer significant advantages. The Pt20-DW's vibration resistance of ≥40g acceleration and shock resistance of ≥100g acceleration make it suitable for use in vehicles and aircraft where mechanical stresses are common. These sensors play crucial roles in engine management systems, environmental controls, and safety mechanisms, contributing to improved efficiency and reliability in transportation technologies.

Medical and Healthcare Innovations

The medical field benefits greatly from the precision and rapid response of thin film platinum resistors. In applications such as medical imaging equipment, diagnostic devices, and patient monitoring systems, these sensors provide the accuracy and reliability essential for critical healthcare decisions. The thin film platinum resistor Pt20-DW's small size allows for non-invasive and minimally invasive temperature measurements, enhancing patient comfort and diagnostic capabilities.

Future Trends and Developments

As technology continues to advance, the role of thin film platinum resistors in various industries is expected to grow. Ongoing research and development efforts are focused on further miniaturization, enhanced sensitivity, and improved integration with digital systems. The trend towards Internet of Things (IoT) and smart manufacturing is likely to drive increased demand for these high-performance sensors, as they provide the precise data needed for advanced control and monitoring systems.

Conclusion

In the comparison between thin film and wire wound platinum resistors, the thin film technology, exemplified by the thin film platinum resistor Pt20-DW, demonstrates superior performance in many critical areas. Its compact size, rapid response time, high accuracy, and excellent stability make it the preferred choice for applications requiring precise temperature measurement. While wire wound resistors still have their place in certain scenarios, the advantages of thin film technology are driving its adoption across various industries, from industrial processes to cutting-edge medical devices.

As we look to the future, the continued development and refinement of thin film platinum resistors promise even greater advancements in temperature sensing technology. For those seeking to leverage these high-performance sensors in their applications, Xi'an Tongzida Technology Co., Ltd. offers expertise and customized solutions. To explore how the thin film platinum resistor Pt20-DW can enhance your temperature measurement capabilities, contact us at sales11@xatzd.com.

References

1. Childs, P. R. N., Greenwood, J. R., & Long, C. A. (2000). Review of temperature measurement. Review of Scientific Instruments, 71(8), 2959-2978.

2. Michalski, L., Eckersdorf, K., Kucharski, J., & McGhee, J. (2001). Temperature Measurement (2nd ed.). John Wiley & Sons.

3. Buhanan, A., & Delport, G. (2017). Platinum Resistance Thermometry: A Comparison of Thin-Film and Wire-Wound Technologies. Measurement and Control, 50(7), 203-208.

4. Dunn, P. F. (2014). Measurement and Data Analysis for Engineering and Science (3rd ed.). CRC Press.

5. Lipták, B. G. (Ed.). (2003). Instrument Engineers' Handbook, Volume One: Process Measurement and Analysis (4th ed.). CRC Press.

Learn about our latest products and discounts through SMS or email