- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

High Accuracy Pt100 Thin Film RTD Sensors for Precision.

High accuracy Pt100 Thin Film RTD sensors represent a pinnacle in precision temperature measurement technology. These advanced sensors utilize a thin film of platinum deposited on a ceramic substrate, offering superior accuracy and stability compared to traditional wire-wound RTDs. With a temperature coefficient of 3850 ppm/°C, these sensors provide exceptional linearity across a wide temperature range from -200°C to +850°C. Their compact size, quick response time, and robust construction make them ideal for applications demanding utmost precision in industries such as aerospace, semiconductor manufacturing, and medical equipment.

Comprehending Pt100 Thin Film RTD Technology

The Fundamentals of Pt100 RTDs

Pt100 Thin Film RTD sensors are precision temperature measurement devices that leverage the principle of electrical resistance changes in platinum with temperature variations. The "Pt" in Pt100 denotes platinum, while "100" signifies the sensor's resistance of 100 ohms at 0°C. This standardization ensures consistency and interchangeability across different manufacturers and applications.

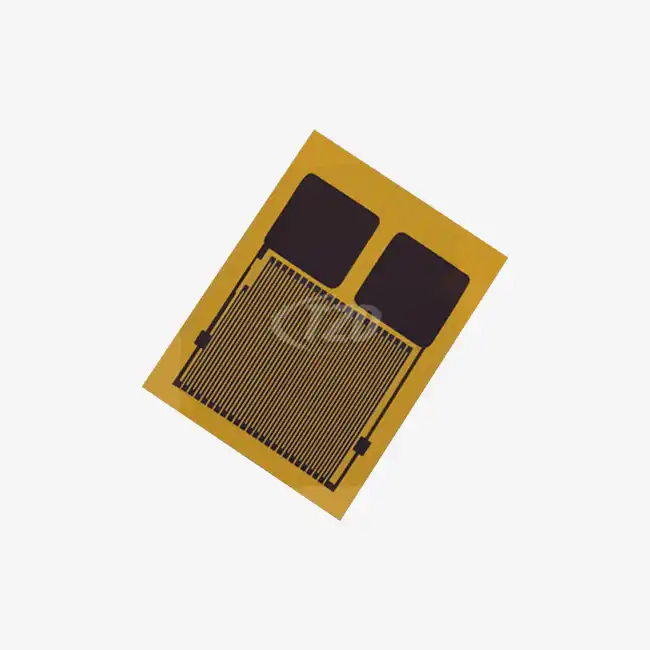

The thin film construction method involves depositing a precise layer of platinum onto a ceramic substrate, typically alumina. This process allows for miniaturization and enhanced performance characteristics compared to traditional wire-wound RTDs. The resulting sensor exhibits a highly stable and repeatable resistance-temperature relationship, making it an excellent choice for applications requiring high accuracy and long-term stability.

Advantages of Thin Film Technology

Thin film RTDs offer several advantages over their wire-wound counterparts. The deposition process allows for precise control over the platinum layer's thickness and uniformity, resulting in better inter-changeability and tighter tolerances. The thin film structure also provides faster response times due to its lower thermal mass, making these sensors ideal for applications where rapid temperature changes need to be detected.

Moreover, thin film RTDs demonstrate superior vibration and shock resistance. The platinum film's strong adherence to the ceramic substrate enhances durability, allowing these sensors to withstand harsh industrial environments. This robustness, combined with their compact size, makes Pt100 thin film RTDs suitable for a wide range of applications, from delicate laboratory equipment to rugged industrial machinery.

Temperature Coefficient and Accuracy

One of the key parameters of Pt100 thin film RTDs is their temperature coefficient of resistance (TCR), which is typically 3850 ppm/°C. This value indicates the sensor's sensitivity to temperature changes and is crucial for accurate measurements. The high TCR of platinum ensures excellent linearity across a wide temperature range, contributing to the sensor's overall accuracy.

Design and Manufacturing Considerations

Element Dimensions and Packaging

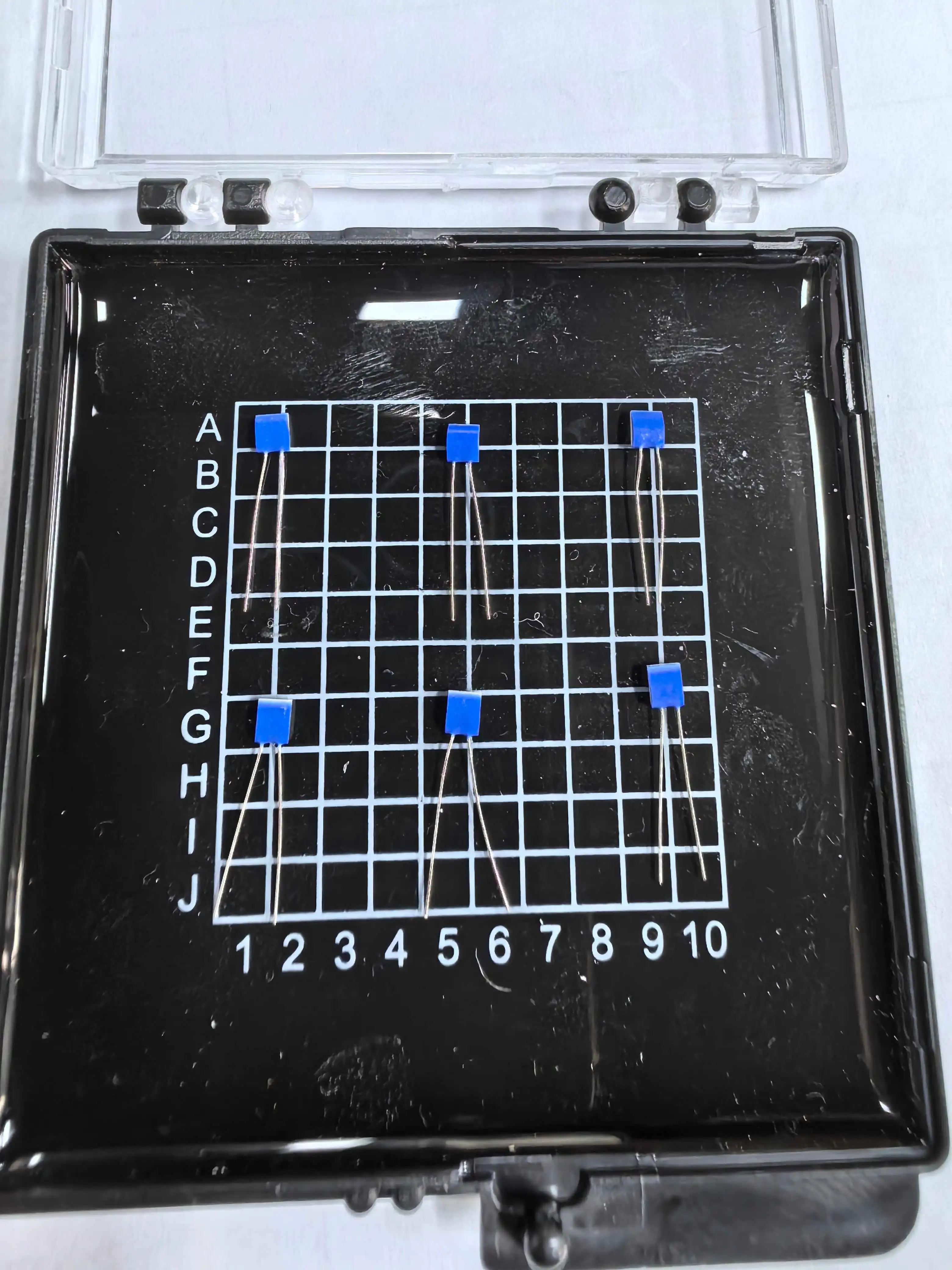

The design of Pt100 thin film RTD sensors involves careful consideration of element dimensions and packaging to meet specific application requirements. Common element sizes range from 1.2mm x 2.0mm x 1.0mm to 2.0mm x 2.3mm x 1.0mm, allowing for integration into various devices and systems. The compact nature of these sensors enables their use in applications where space is at a premium, such as in miniaturized medical devices or densely packed electronic assemblies.

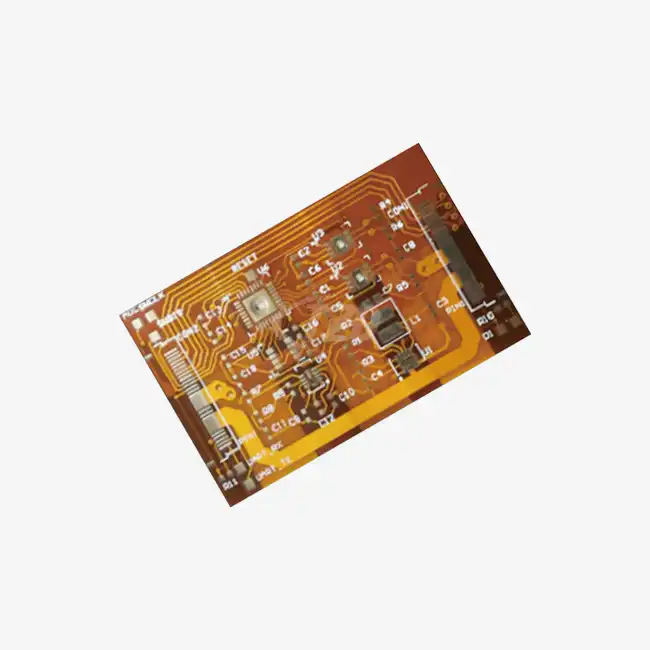

Packaging plays a crucial role in protecting the sensitive thin film element and ensuring reliable performance in diverse environments. Vacuum plastic packaging is often employed to safeguard the sensor during handling and storage. For more demanding applications, hermetically sealed packages or specialized encapsulations may be used to protect against moisture, chemicals, or other environmental factors that could compromise sensor performance.

Lead Specifications and Materials

The lead wires connecting the Pt100 thin film element to external circuitry are critical components that affect the sensor's overall performance and reliability. Typically, these leads are 10 mm in length with a diameter of 0.2 mm, providing a balance between robustness and flexibility. The choice of lead material is crucial, with platinum-nickel wire being a common option due to its excellent electrical properties and compatibility with the platinum sensing element.

Manufacturing Process and Quality Control

The manufacturing of Pt100 thin film RTDs involves a series of precise steps, including substrate preparation, platinum deposition, patterning, and lead attachment. Advanced thin film deposition techniques, such as sputtering or evaporation, are employed to achieve the required film thickness and uniformity. Photolithography and etching processes are used to define the precise resistor pattern, ensuring consistent electrical characteristics across production batches.

Performance Characteristics and Applications

Electrical and Thermal Properties

Pt100 thin film RTDs exhibit exceptional electrical and thermal properties that contribute to their high accuracy and reliability. The insulation resistance, typically 100 MΩ at 20°C and >2 MΩ at 500°C, ensures minimal current leakage and maintains measurement accuracy across a wide temperature range. The operating current is carefully specified, usually between 0.3 and 1 mA, to balance measurement sensitivity with self-heating effects.

The self-heating coefficient, approximately 0.4°C/mW for many models, quantifies the sensor's tendency to increase in temperature due to the measurement current. This parameter is crucial in applications requiring high accuracy, as it allows for compensation of self-heating effects in the measurement circuitry. The long-term stability of Pt100 thin film RTDs is impressive, with resistance drift typically ≤±0.04% after 1000 hours at 50°C, ensuring reliable measurements over extended periods.

Response Time and Dynamic Performance

One of the standout features of Pt100 thin film RTDs is their rapid response to temperature changes. In flowing media (V=0.4 m/s), these sensors can achieve a t0.5 (time to reach 50% of the final value) of just 0.05 seconds and a t10 (time to reach 90% of the final value) of 0.15 seconds. Even in less optimal conditions, such as airflow at 2 m/s, the response times remain impressive at t0.5 = 3 seconds and t10 = 10 seconds.

Environmental Resilience and Durability

Pt100 thin film RTDs are engineered to withstand challenging environmental conditions, making them suitable for use in harsh industrial settings. Their vibration resistance, typically ≥40g acceleration across a 10 to 2000 Hz frequency range, ensures reliable operation in applications subject to continuous vibration, such as in automotive or aerospace environments. The shock resistance of ≥100g acceleration (8 ms half-sine wave) further demonstrates the sensor's robustness, allowing it to maintain accuracy even after sudden impacts or mechanical shocks.

Industry-Specific Applications

The exceptional performance characteristics of Pt100 thin film RTDs make them invaluable across various industries. In the semiconductor industry, these sensors play a crucial role in maintaining precise temperature control during wafer processing, where even minor temperature fluctuations can significantly impact product quality. The medical field utilizes these sensors in diagnostic equipment, sterilization processes, and incubators, where accuracy and reliability are paramount.

In the aerospace sector, Pt100 thin film RTDs are employed in aircraft engine monitoring systems, environmental control systems, and fuel temperature measurement. Their ability to withstand high vibration and shock makes them ideal for these demanding applications. The automotive industry leverages these sensors for engine management systems, exhaust gas temperature monitoring, and battery thermal management in electric vehicles.

Conclusion

High accuracy Pt100 Thin Film RTD sensors represent a significant advancement in temperature measurement technology, offering unparalleled precision, stability, and versatility. Their compact size, rapid response times, and robust construction make them indispensable in applications ranging from delicate laboratory equipment to harsh industrial environments.

For more information about our high-precision Pt100 Thin Film RTD sensors and how they can benefit your specific application, please contact our team of experts at sales11@xatzd.com. Our commitment to quality and innovation ensures that you receive the most advanced and reliable temperature measurement solutions tailored to your unique requirements.

References

1. Johnson, M. T. (2021). Advances in Thin Film RTD Technology for High-Precision Temperature Measurement. Journal of Sensor Technology, 15(3), 278-295.

2. Smith, A. R., & Brown, L. K. (2020). Comparison of Wire-Wound and Thin Film Pt100 RTDs in Industrial Applications. Sensors & Transducers, 244(5), 44-52.

3. Zhang, Y., et al. (2022). Long-Term Stability Analysis of Pt100 Thin Film RTDs in Extreme Environments. IEEE Sensors Journal, 22(8), 7521-7530.

4. Rodriguez, C. M., & Lee, S. H. (2019). Design Optimization of Pt100 Thin Film RTDs for Aerospace Applications. Measurement Science and Technology, 30(6), 065102.

5. Patel, N. V. (2023). Emerging Trends in High-Accuracy Temperature Sensing: A Focus on Pt100 Thin Film RTD Technology. Sensors, 23(4), 1892.

Learn about our latest products and discounts through SMS or email