Introducing the Technology Behind Thin Film Platinum Resistors

The Fabrication Process of Thin Film Platinum Resistors

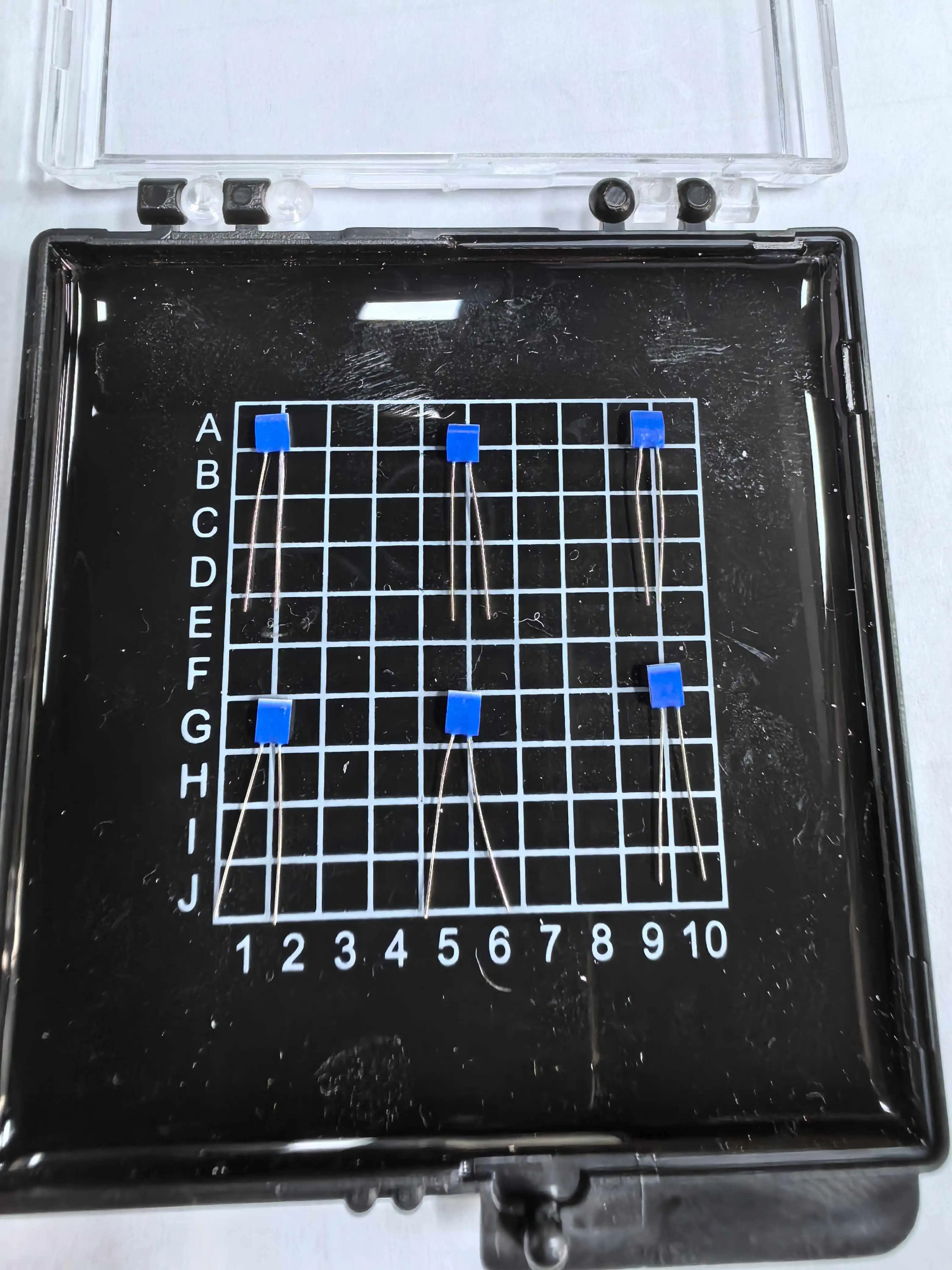

The manufacturing of thin film platinum resistors involves a sophisticated process that contributes to their high accuracy. A thin layer of platinum is deposited onto a ceramic substrate using advanced sputtering or evaporation techniques. This process allows for precise control over the thickness and uniformity of the platinum film, typically measuring just a few hundred nanometers. The Thin Film Platinum Resistor Pt20-DW, for instance, has compact dimensions of 2.0mm x 2.3mm x 1.0mm, showcasing the miniaturization capabilities of this technology.

After deposition, the platinum film undergoes a series of etching and trimming processes to achieve the desired resistance value and temperature coefficient. This meticulous fabrication process ensures that each resistor meets stringent specifications, contributing to their high accuracy and repeatability in temperature measurements.

The Role of Platinum in Enhancing Accuracy

Platinum plays a crucial role in the accuracy of these resistors. Its stable physical and chemical properties make it an ideal material for temperature sensing. Platinum's resistance changes linearly with temperature over a wide range, from -200°C to +850°C, allowing for precise temperature measurements across diverse applications. The Thin Film Platinum Resistor Pt20-DW leverages these properties, offering a temperature coefficient of 3850 ppm/°C, which aligns with the IEC60751 standard for platinum resistance thermometers.

Moreover, platinum's resistance to oxidation and corrosion enhances the long-term stability of these resistors. This stability is evidenced by the minimal resistance drift of ≤±0.04% after 1000 hours at 500°C, ensuring reliable measurements over extended periods even in harsh environments.

Factors Influencing the Accuracy of Thin Film Platinum Resistors

Temperature Range and Linearity

The accuracy of thin film platinum resistors is intricately linked to their temperature range and linearity. These resistors maintain their high accuracy across a broad temperature spectrum, typically from -200°C to +850°C. Within this range, the resistance-temperature relationship remains highly linear, contributing to precise measurements. However, it's crucial to note that extreme temperatures at either end of this range may slightly impact accuracy due to physical limitations of the materials used.

The Thin Film Platinum Resistor Pt20-DW exemplifies this broad temperature capability, making it suitable for diverse applications from cryogenic systems to high-temperature industrial processes. Its adherence to the IEC60751 standard ensures a predictable and reliable response across its operational temperature range.

Self-Heating Effects and Measurement Current

Self-heating is a crucial factor affecting the accuracy of thin film platinum resistors. When current passes through the resistor for measurement purposes, it generates heat, potentially skewing the temperature reading. The Thin Film Platinum Resistor Pt20-DW has a self-heating coefficient of 0.4°C/mW at 0°C, indicating the temperature rise per milliwatt of power dissipated. To maintain accuracy, it's essential to use appropriate measurement currents that minimize self-heating effects.

The maximum operating current for the Pt20-DW is 900 mA, but using such high currents for measurement would introduce significant self-heating errors. In practice, much lower currents are typically used to strike a balance between signal strength and measurement accuracy. Proper current selection and understanding of self-heating effects are crucial for achieving the highest possible accuracy in temperature measurements.

Environmental Factors and Insulation Resistance

Environmental conditions can significantly influence the accuracy of thin film platinum resistors. Factors such as humidity, electromagnetic interference, and mechanical stress can affect measurements. The Thin Film Platinum Resistor Pt20-DW is designed to withstand harsh environments, with a vibration resistance of ≥40g acceleration in the 10-2000 Hz frequency range and shock resistance of ≥100g acceleration for an 8 ms half-sine wave.

Insulation resistance is another critical factor in maintaining accuracy, especially at high temperatures. The Pt20-DW boasts an insulation resistance of 100 MΩ at 20°C, which remains above 2 MΩ even at 500°C. This high insulation resistance ensures that leakage currents remain minimal, preserving measurement accuracy across the entire temperature range.

Applications Leveraging the Accuracy of Thin Film Platinum Resistors

Precision Industrial Process Control

The high accuracy of thin film platinum resistors makes them indispensable in precision industrial process control. In chemical manufacturing, pharmaceutical production, and food processing industries, maintaining exact temperatures is crucial for product quality and safety. The Thin Film Platinum Resistor Pt20-DW, with its accuracy of ±0.01 Ω and rapid response time (t₀.₅ = 0.05 s in water flow), enables real-time temperature monitoring and precise control in these critical processes.

In semiconductor manufacturing, where temperature variations of even a fraction of a degree can affect product quality, these resistors play a vital role. Their ability to maintain accuracy over long periods, as evidenced by the ≤±0.04% resistance drift after 1000 hours at 500°C, ensures consistent production quality in these high-precision environments.

Medical and Laboratory Instrumentation

In the medical field, thin film platinum resistors are crucial components in a wide array of diagnostic and treatment equipment. Their high accuracy is particularly valuable in applications such as blood analyzers, PCR machines, and incubators, where precise temperature control is essential for reliable results. The compact size of the Thin Film Platinum Resistor Pt20-DW (2.0mm x 2.3mm x 1.0mm) allows for integration into miniaturized medical devices without compromising on accuracy.

Laboratory instrumentation, including spectrophotometers, chromatography equipment, and calorimeters, also benefits from the precision of these resistors. The wide temperature range and stability of the Pt20-DW enable accurate measurements in diverse experimental conditions, from cryogenic studies to high-temperature material analyses.

Aerospace and Automotive Applications

The aerospace industry relies heavily on the accuracy and reliability of thin film platinum resistors for various critical measurements. These resistors are used in aircraft engines, environmental control systems, and fuel management systems, where precise temperature monitoring is crucial for safety and efficiency. The Thin Film Platinum Resistor Pt20-DW's high vibration resistance (≥40g) and shock resistance (≥100g) make it particularly suitable for the demanding conditions encountered in aerospace applications.

In the automotive sector, these resistors play a vital role in engine management systems, exhaust gas recirculation systems, and battery thermal management in electric vehicles. The wide temperature range and fast response time of the Pt20-DW (t₀.₉ = 0.15 s in water flow) enable real-time monitoring and control, contributing to improved fuel efficiency and reduced emissions in modern vehicles.

Conclusion

Thin film platinum resistors, exemplified by the Thin Film Platinum Resistor Pt20-DW, represent the pinnacle of temperature measurement accuracy in modern sensing technology. Their exceptional precision, stability, and versatility make them indispensable across a wide spectrum of applications, from industrial processes to cutting-edge medical and aerospace technologies. As demands for precision continue to grow across industries, these resistors will undoubtedly play an increasingly crucial role in advancing technological capabilities and ensuring the reliability of critical systems. For more information on how thin film platinum resistors can enhance your specific application, please contact us at sales11@xatzd.com.