Understanding the Technology Behind Thin Film Pt100 Sensors

The Composition and Manufacturing Process

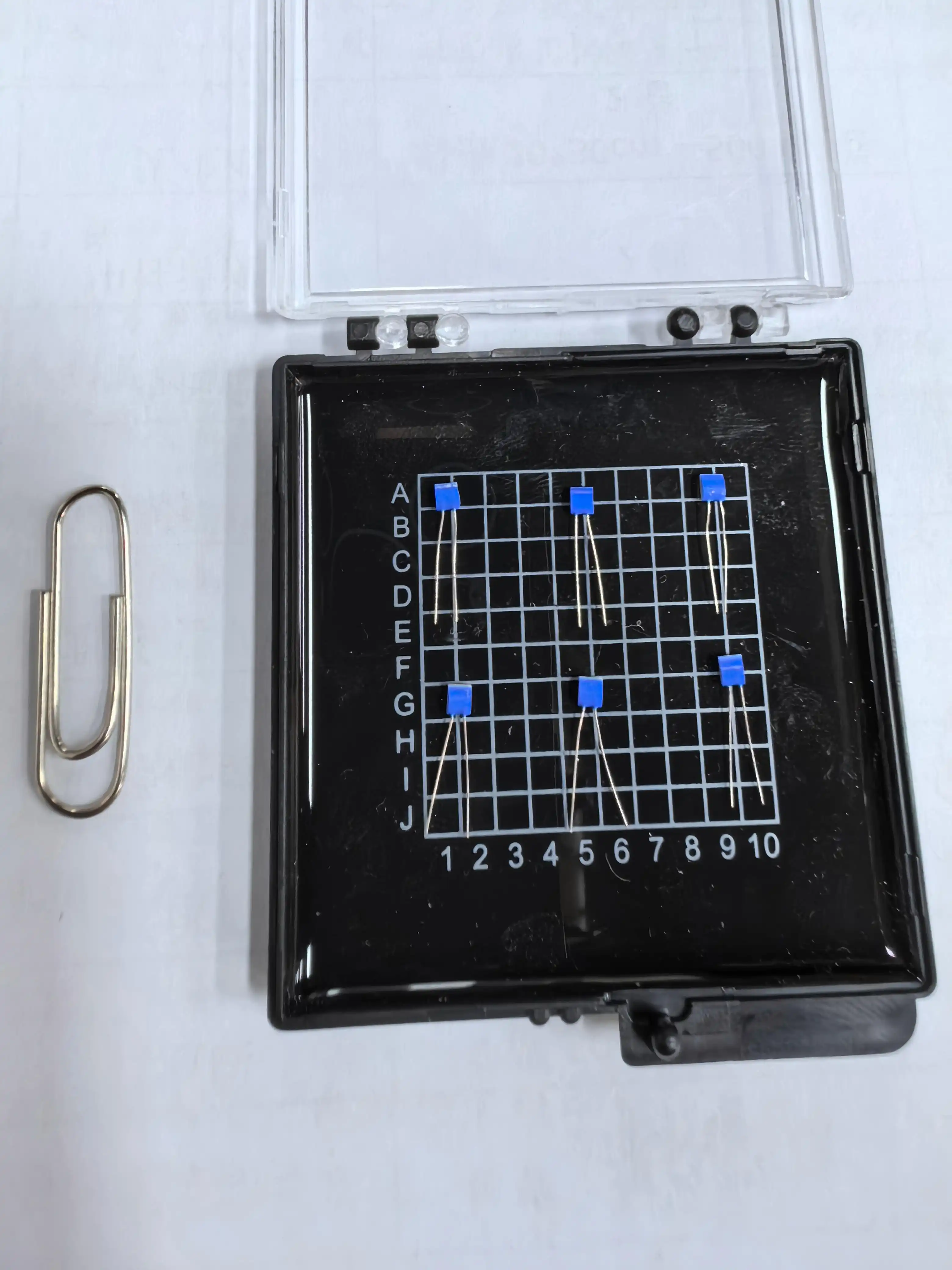

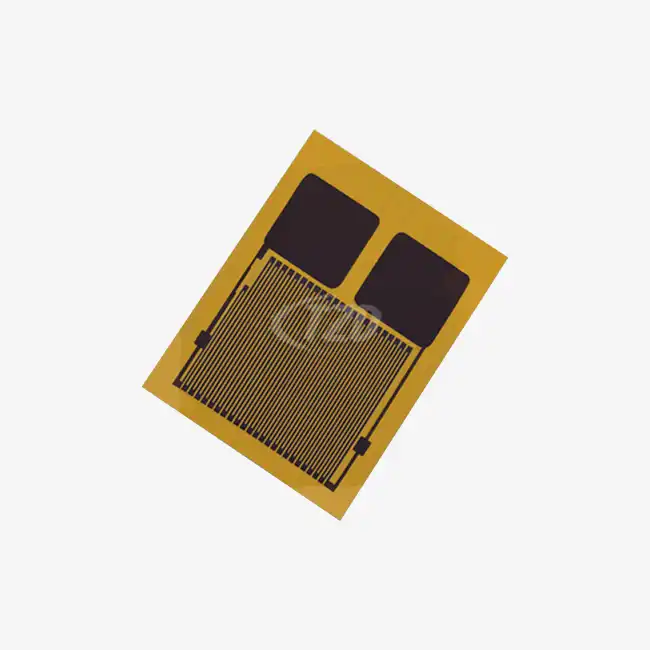

Thin Film Pt100 Sensors are meticulously crafted using advanced technology. The manufacturing process involves depositing a thin layer of platinum onto a ceramic substrate, typically measuring between 1.2mm to 2.3mm in length and 1.0mm in thickness. This precision engineering results in a compact yet highly sensitive temperature measurement device.

The platinum layer, which forms the sensing element, is carefully etched to achieve the desired resistance characteristics. The sensor's leads, often made of platinum-nickel wire or other materials like silver-palladium, are then attached. These leads, typically 10mm in length and 0.2mm in diameter, provide a robust connection with a tensile strength of ≥9 N, ensuring durability in various applications.

Key Performance Characteristics

Thin Film Pt100 Sensors are designed to meet rigorous performance standards. They exhibit a temperature coefficient (TCR) of 3850 ppm/°C, aligning with the IEC60751 standard. This characteristic ensures consistent and accurate temperature readings across a wide range, from -200°C to +850°C.

The sensors operate with a current between 0.3 and 1 mA, with considerations for self-heating effects. Their self-heating coefficient is approximately 0.4°C/mW, which is crucial for maintaining accuracy in low-power applications. The insulation resistance is impressive, measuring 100 MΩ at 20°C and remaining above 2 MΩ even at elevated temperatures of 500°C.

One of the standout features of these sensors is their rapid response time. In flowing conditions (V=0.4 m/s), they achieve a t0.5 of 0.05 seconds and a t10 of 0.15 seconds. Even in airflow conditions (V=2 m/s), the response times are commendable at t0.5 = 3 seconds and t10 = 10 seconds. This quick response enables real-time temperature monitoring in dynamic environments.

Advantages of Thin Film Pt100 Sensors in Various Applications

Industrial and Manufacturing Sector

In industrial settings, Thin Film Pt100 Sensors prove invaluable due to their robustness and reliability. Their ability to withstand vibrations of ≥40g acceleration in the 10 to 2000 Hz frequency range makes them suitable for machinery and equipment exposed to continuous vibrations. The shock resistance of ≥100g acceleration (8 ms half-sine wave) further enhances their durability in harsh industrial environments.

The long-term stability of these sensors is particularly beneficial in manufacturing processes. With a resistance drift of ≤±0.04% after 1000 hours at 500°C, they ensure consistent and accurate temperature readings over extended periods. This stability is crucial for maintaining product quality and process efficiency in industries such as chemical processing, food production, and metallurgy.

Automotive and Aerospace Applications

The automotive and aerospace industries benefit greatly from the compact size and high performance of Thin Film Pt100 Sensors. Their small dimensions (as little as 1.2mm x 2.0mm x 1.0mm) allow for integration into tight spaces within engines, exhaust systems, and avionics equipment. The wide temperature range coverage is particularly advantageous in these sectors, where extreme temperature variations are common.

The sensors' ability to maintain accuracy under high vibration and shock conditions is crucial for vehicle and aircraft safety systems. Their rapid response time enables real-time monitoring of critical components, enhancing overall system performance and safety. The long-term stability ensures reliable temperature measurements throughout the lifecycle of automotive and aerospace applications, reducing maintenance needs and improving operational efficiency.

Medical and Laboratory Equipment

In medical and laboratory settings, the precision and reliability of Thin Film Pt100 Sensors are paramount. Their high accuracy (±0.01 Ω) is essential for applications such as medical diagnostics, temperature-controlled incubators, and precision laboratory equipment. The sensors' quick response time allows for rapid detection of temperature changes, critical in maintaining stable conditions for sensitive experiments or medical procedures.

The sensors' compatibility with various lead materials, including platinum-nickel, silver-palladium, and pure platinum, offers flexibility in design for different medical devices. Their low self-heating coefficient is particularly beneficial in applications where minimal interference with the measured environment is crucial, such as in biological sample storage or sensitive analytical instruments.

Future Trends and Innovations in Thin Film Pt100 Sensor Technology

Advancements in Miniaturization and Integration

The future of Thin Film Pt100 Sensors is moving towards even greater miniaturization. Research and development efforts are focused on creating sensors with dimensions smaller than the current 1.2mm x 2.0mm x 1.0mm, while maintaining or improving performance characteristics. This trend towards miniaturization will enable integration into increasingly compact devices and open up new applications in fields such as wearable technology and microfluidics.

Advancements in integration technologies are also on the horizon. Future sensors may incorporate multiple sensing elements or combine temperature sensing with other parameters like pressure or humidity in a single package. This integration will lead to more comprehensive and efficient sensing solutions, particularly beneficial in IoT (Internet of Things) applications and smart manufacturing environments.

Enhanced Performance and Specialized Applications

Ongoing research is aimed at pushing the boundaries of Thin Film Pt100 Sensor performance. Efforts are being made to extend the temperature range beyond the current -200°C to +850°C, potentially opening up new applications in extreme environments such as space exploration or deep-sea research. Improvements in long-term stability and accuracy are also being pursued, with the goal of achieving even lower drift rates than the current ≤±0.04% after 1000 hours at high temperatures.

Specialized versions of these sensors are being developed for niche applications. For instance, sensors with enhanced resistance to specific chemicals or radiation are being created for use in nuclear facilities or aggressive chemical processing environments. There's also a focus on developing sensors with even faster response times, potentially reaching sub-millisecond levels, which could revolutionize applications in high-speed thermal management systems.

Sustainability and Environmental Considerations

As environmental concerns become increasingly important, the development of Thin Film Pt100 Sensors is also focusing on sustainability. Research is underway to find alternative materials that can match or exceed the performance of platinum while being more environmentally friendly or using less rare materials. This includes exploring composite materials or novel alloys that can provide similar temperature coefficients and stability.

Additionally, efforts are being made to improve the energy efficiency of these sensors, reducing their power consumption without compromising performance. This is particularly important for battery-powered and energy-harvesting applications, where every milliwatt of power consumption matters. The development of more efficient manufacturing processes is also a priority, aiming to reduce waste and energy use in sensor production.

Conclusion

Thin Film Pt100 Sensors represent a pinnacle in temperature measurement technology, offering unparalleled accuracy, stability, and versatility across a wide range of applications. Their compact size, rapid response, and durability make them indispensable in industries ranging from aerospace to healthcare. As technology continues to advance, these sensors are poised to become even more integral to our technological landscape, driving innovations in temperature sensing and control.

For those seeking cutting-edge temperature measurement solutions, Thin Film Pt100 Sensors offer a compelling choice. Their ability to provide precise, reliable measurements in challenging environments makes them an invaluable tool for engineers and scientists alike. As we look to the future, the continued evolution of these sensors promises to unlock new possibilities in temperature sensing, further enhancing their role in advancing technology and improving processes across various industries.

To learn more about our advanced Thin Film Pt100 Sensors and how they can benefit your specific application, please contact us at sales11@xatzd.com. Our team of experts is ready to assist you in finding the perfect temperature sensing solution for your needs.