Introducing the Pt100 Temperature Sensing Element

What is a Pt100 Temperature Sensing Element?

A Pt100 Temperature Sensing Element is a type of Resistance Temperature Detector (RTD) that utilizes the predictable change in electrical resistance of platinum with temperature to measure ambient conditions. The "Pt" in Pt100 stands for platinum, while "100" indicates that the sensor has a resistance of 100 ohms at 0°C. This specific resistance-temperature relationship forms the basis for its functionality.

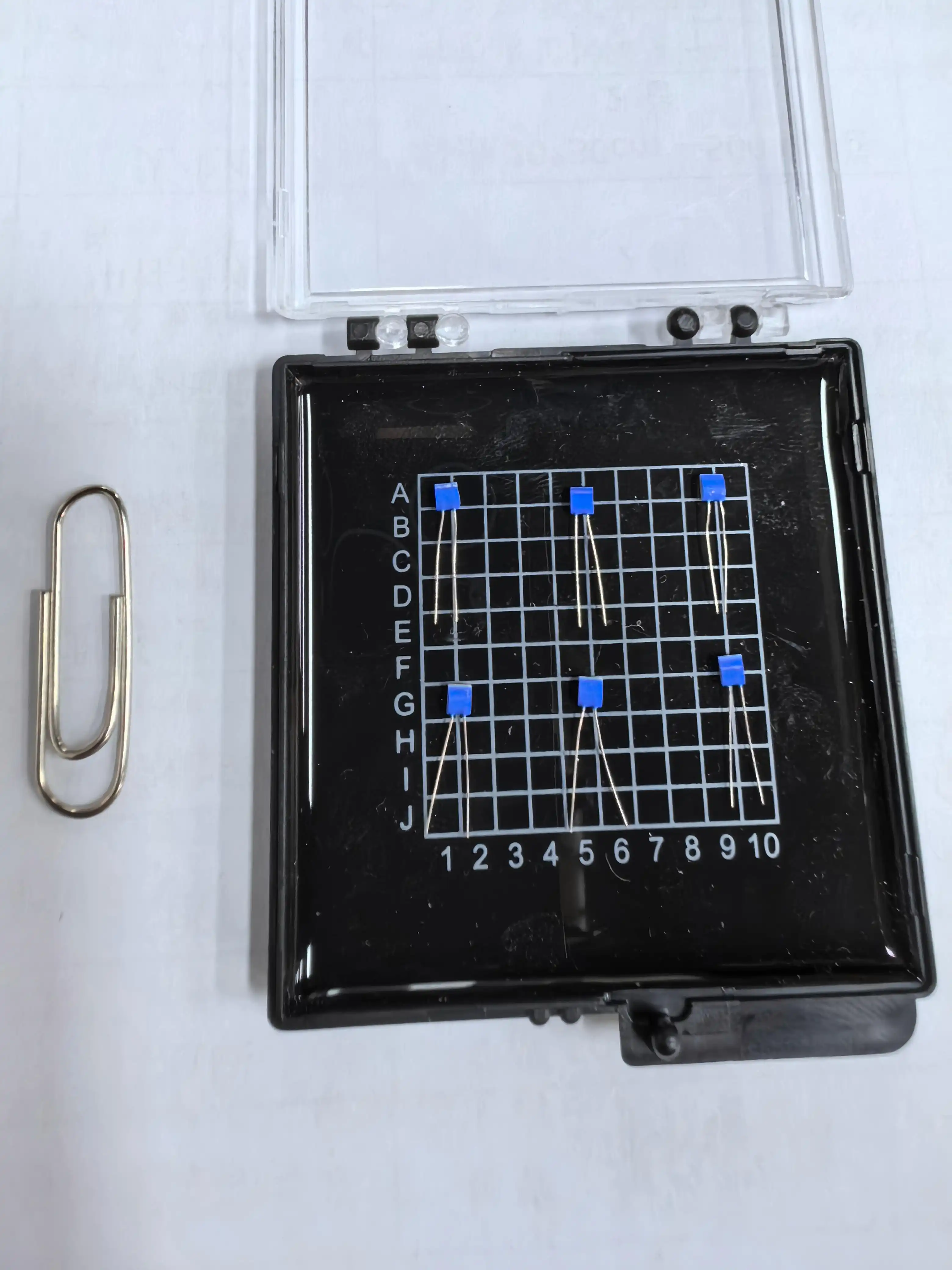

Pt100 elements are typically constructed as thin-film platinum resistance thermistors. These miniature marvels come in various dimensions, such as 2.0mm x 2.3mm x 1.0mm, 1.6mm x 2.0mm x 1.0mm, and 1.2mm x 2.0mm x 1.0mm, allowing for versatile application in confined spaces. The sensing element is connected to lead wires, often made of platinum-nickel alloy, with a length of about 10 mm and a diameter of 0.2 mm. These leads boast impressive tensile strength, capable of withstanding forces of 9 N or more.

How Does a Pt100 Temperature Sensing Element Work?

The operation of a Pt100 Temperature Sensing Element relies on the principle of electrical resistance changing with temperature. As the ambient temperature fluctuates, the resistance of the platinum element changes in a predictable and repeatable manner. This change in resistance is then measured and converted into a corresponding temperature reading.

The relationship between resistance and temperature in a Pt100 sensor is nearly linear, with a temperature coefficient (TCR) of 3850 ppm/°C. This means that for every degree Celsius change in temperature, the resistance of the Pt100 element changes by 0.385 ohms. This predictable behavior allows for accurate temperature measurements across a wide range.

To measure temperature, a small current (typically between 0.3 and 1 mA) is passed through the Pt100 element. The voltage drop across the element is then measured, and using Ohm's law, the resistance is calculated. This resistance value is then converted to a temperature reading using standardized tables or equations.

Factors Affecting the Accuracy of Pt100 Temperature Sensing Elements

Material Purity and Construction

The accuracy of a Pt100 Temperature Sensing Element is heavily influenced by the purity of the platinum used in its construction. High-purity platinum ensures a more consistent and predictable resistance-temperature relationship. The thin-film construction technique employed in modern Pt100 sensors allows for precise control over the element's composition and dimensions, contributing to improved accuracy.

The quality of the lead wires and their connection to the sensing element also play a crucial role in accuracy. Premium Pt100 sensors often utilize platinum-nickel alloy leads, which offer excellent conductivity and resist corrosion. Some manufacturers also offer alternative lead materials such as silver-palladium, pure platinum, or silver-nickel to suit specific application requirements.

Environmental Factors and Calibration

While Pt100 Temperature Sensing Elements are inherently accurate, their performance can be affected by environmental factors. Extreme temperatures, humidity, and electromagnetic interference can all impact measurement accuracy. To mitigate these effects, high-quality Pt100 sensors are designed with robust insulation, capable of maintaining an insulation resistance of 100 MΩ at 20°C and over 2 MΩ at temperatures as high as 500°C.

Regular calibration is essential to maintain the accuracy of Pt100 sensors over time. The long-term stability of these sensors is impressive, with resistance drift typically less than ±0.04% after 1000 hours of operation at 500°C. However, periodic recalibration ensures that the sensor continues to meet specified accuracy levels throughout its operational life.

Self-Heating and Response Time

One factor that can affect the accuracy of Pt100 Temperature Sensing Elements is self-heating. When current passes through the sensor, it generates a small amount of heat, which can slightly elevate the temperature of the element above that of its surroundings. High-quality Pt100 sensors have a low self-heating coefficient, typically around 0.4°C/mW, minimizing this effect.

The response time of a Pt100 sensor is another crucial factor in its accuracy, especially in dynamic temperature environments. Advanced thin-film Pt100 elements offer impressively fast response times. In flowing liquids (V=0.4 m/s), they can achieve a t0.5 (time to reach 50% of the final value) of 0.05 seconds and a t10 (time to reach 90% of the final value) of 0.15 seconds. Even in air (V = 2 m/s), response times are relatively quick, with t0.5 = 3 seconds and t10 = 10 seconds.

Applications and Advantages of Pt100 Temperature Sensing Elements

Industrial and Scientific Applications

The high accuracy and stability of Pt100 Temperature Sensing Elements make them indispensable in a wide range of industrial and scientific applications. In manufacturing processes, they are used to monitor and control temperatures in furnaces, ovens, and reactors. In the food and beverage industry, Pt100 sensors ensure precise temperature control during processing and storage. In scientific research, these sensors are relied upon for accurate temperature measurements in laboratories and experimental setups.

The robustness of Pt100 sensors is particularly valuable in harsh industrial environments. With vibration resistance of ≥40g acceleration across a frequency range of 10 to 2000 Hz and shock resistance of ≥100g acceleration (8 ms half-sine wave), these sensors can withstand the rigors of industrial use while maintaining their accuracy.

Medical and Aerospace Applications

In the medical field, Pt100 Temperature Sensing Elements are used in a variety of diagnostic and therapeutic equipment. Their accuracy is crucial in applications such as incubators, blood warmers, and sterilization equipment. The ability to customize Pt100 sensors in various sizes (from 1.2mm to 4.0mm) allows for integration into compact medical devices.

The aerospace industry also relies heavily on the accuracy and reliability of Pt100 sensors. These elements are used in aircraft engines, environmental control systems, and fuel systems where precise temperature monitoring is critical for safety and efficiency. The wide temperature range (-200°C to +850°C) and excellent long-term stability of Pt100 sensors make them ideal for these demanding applications.

Advantages Over Other Temperature Sensing Technologies

Pt100 Temperature Sensing Elements offer several advantages over other temperature measurement technologies. Compared to thermocouples, Pt100 sensors provide higher accuracy and stability, especially over long periods. Unlike thermistors, which can have highly non-linear resistance-temperature relationships, Pt100 sensors offer near-linear response, simplifying calibration and measurement processes.

The interchangeability of Pt100 sensors is another significant advantage. Due to their standardized characteristics (conforming to IEC60751), Pt100 sensors from different manufacturers can often be used interchangeably without recalibration of the measurement system. This standardization reduces maintenance costs and simplifies inventory management in industrial settings.

Conclusion

Pt100 Temperature Sensing Elements represent the pinnacle of accuracy in temperature measurement technology. Their combination of high precision, long-term stability, and versatility makes them invaluable across a wide spectrum of applications. From industrial process control to cutting-edge medical devices and aerospace systems, Pt100 sensors continue to play a crucial role in ensuring accurate and reliable temperature measurements.

As technology advances, we can expect to see further refinements in Pt100 sensor design, potentially leading to even greater accuracy and faster response times. For those seeking the utmost in temperature measurement precision, Pt100 Temperature Sensing Elements remain the gold standard. If you're interested in learning more about these remarkable sensors or exploring how they can benefit your specific application, don't hesitate to reach out to us at sales11@xatzd.com for expert guidance and support.