The Science Behind Thin Film Pt100 Sensors in Medical Applications

Thin Film Pt100 Sensors, a type of platinum resistance thermometer (PRT), are at the forefront of temperature sensing technology in the medical field. These sensors leverage the principle of electrical resistance change in platinum with temperature variations. The "100" in Pt100 denotes the sensor's resistance of 100 ohms at 0°C, providing a reliable reference point for precise temperature measurements.

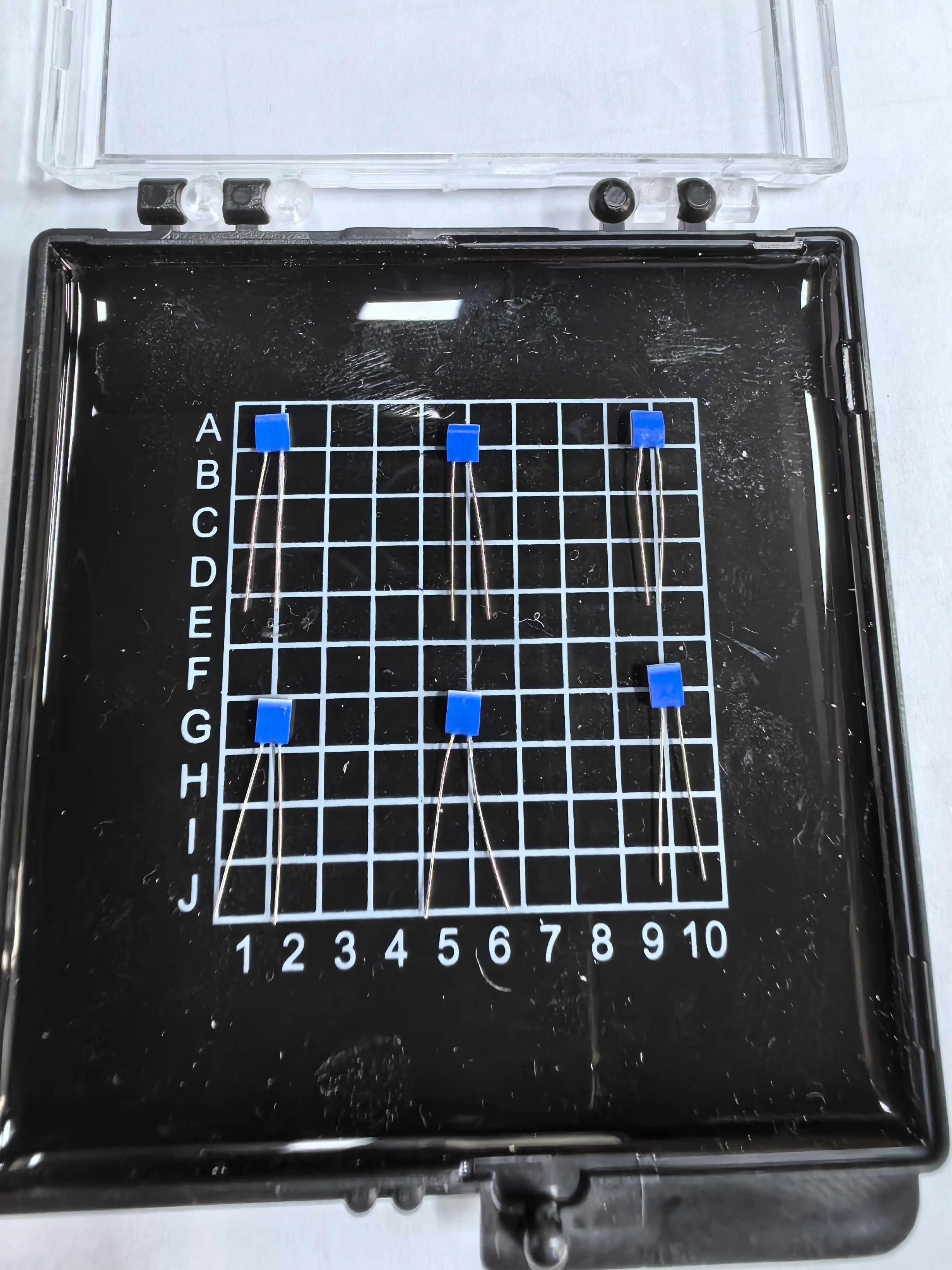

The thin-film construction of these sensors involves depositing a thin layer of platinum onto a ceramic substrate. This method allows for exceptionally small sensor sizes, with some variants measuring just 1.2mm x 2.0mm x 1.0mm. The miniature dimensions make these sensors ideal for integration into compact medical devices without compromising on performance.

Unmatched Precision and Stability

One of the key attributes that sets Thin Film Pt100 Sensors apart is their remarkable precision. With a temperature coefficient (TCR) of 3850 ppm/°C, these sensors exhibit a highly linear and predictable response to temperature changes. This characteristic ensures accurate readings across a wide temperature range, typically from -200°C to +850°C, encompassing all physiological and most pathological temperature ranges encountered in medical scenarios.

The long-term stability of Thin Film Pt100 Sensors is equally impressive. With a resistance drift of ≤±0.04% after 1000 hours at 500°C, these sensors maintain their accuracy over extended periods. This stability is crucial in medical applications where consistent and reliable measurements are paramount for patient safety and treatment efficacy.

Rapid Response and Sensitivity

In medical settings, where quick decisions can be life-saving, the response time of temperature sensors is critical. Thin Film Pt100 Sensors excel in this aspect, with response times as low as t0.5 = 0.05 seconds in flowing conditions. This rapid response enables real-time temperature monitoring in applications such as continuous patient temperature tracking or thermal management in medical imaging equipment.

The sensors' high sensitivity, coupled with a low self-heating coefficient of 0.4°C/mW, allows for precise measurements with minimal interference from the sensor itself. This characteristic is particularly valuable in applications where even slight temperature variations can be indicative of physiological changes or equipment performance issues.

Integration and Durability in Medical Devices

The integration of Thin Film Pt100 Sensors into medical devices is facilitated by their compact size and robust construction. These sensors are available in various dimensions, ranging from 1.2mm x 2.0mm x 1.0mm to 2.0mm x 2.3mm x 1.0mm, allowing for flexible integration into diverse medical equipment designs.

Resilience in Demanding Environments

Medical devices often operate in challenging environments, subjected to vibrations, shocks, and frequent handling. Thin Film Pt100 Sensors are engineered to withstand these conditions. With vibration resistance of ≥40g acceleration in the 10 to 2000 Hz frequency range and shock resistance of ≥100g acceleration for 8 ms half-sine waves, these sensors maintain their performance integrity even in portable or handheld medical devices.

The durability of these sensors is further enhanced by their lead specifications. With lead lengths of 10 mm and diameters of 0.2 mm, coupled with a tensile strength of ≥9 N, the sensors can withstand the rigors of assembly processes and daily use in medical settings. The option for different lead materials, including platinum-nickel wire, silver-palladium, pure platinum, or silver-nickel, allows for customization based on specific application requirements.

Electrical Characteristics for Medical Precision

The electrical properties of Thin Film Pt100 Sensors are tailored for medical applications where accuracy is paramount. With an insulation resistance of 100 MΩ at 20°C and >2 MΩ at 500°C, these sensors maintain excellent signal integrity even at elevated temperatures. This high insulation resistance ensures that the temperature readings are not compromised by electrical leakage, a critical factor in medical diagnostics and patient monitoring equipment.

The sensors operate with a current range of 0.3 to 1 mA, balancing sensitivity with minimal self-heating effects. This low operating current is particularly beneficial in battery-powered medical devices, contributing to extended operational times without sacrificing measurement accuracy.

Applications and Future Prospects in Medical Technology

The versatility and precision of Thin Film Pt100 Sensors have led to their widespread adoption across various medical applications. From patient temperature monitoring systems to sophisticated diagnostic equipment, these sensors are integral to ensuring accurate and reliable temperature measurements.

Current Medical Applications

In patient care, Thin Film Pt100 Sensors are employed in body temperature monitoring devices, offering rapid and accurate readings crucial for assessing patient health. Their small size and flexibility allow for non-invasive temperature measurements, enhancing patient comfort while maintaining precision.

In laboratory settings, these sensors play a vital role in maintaining precise temperature control in incubators, centrifuges, and PCR machines. The stability and accuracy of Thin Film Pt100 Sensors ensure that sensitive biological samples and reagents are maintained at optimal temperatures, critical for research integrity and reproducibility of results.

Medical imaging equipment, such as MRI machines, relies on these sensors for thermal management. The sensors' ability to provide accurate temperature readings in high electromagnetic fields makes them invaluable in ensuring the safe and efficient operation of these sophisticated diagnostic tools.

Emerging Trends and Future Applications

The future of Thin Film Pt100 Sensors in medical technology looks promising, with emerging trends pointing towards even more innovative applications. The miniaturization of these sensors opens up possibilities for integration into wearable medical devices, enabling continuous health monitoring outside traditional healthcare settings.

Advancements in sensor technology are also paving the way for multi-parameter sensing capabilities. Future iterations of Thin Film Pt100 Sensors might incorporate additional sensing modalities, such as pressure or humidity sensing, providing a more comprehensive health monitoring solution in a single, compact package.

The potential for these sensors in telemedicine and remote patient monitoring is particularly exciting. As healthcare systems worldwide move towards more decentralized models, the precision and reliability of Thin Film Pt100 Sensors could play a crucial role in ensuring accurate data collection for remote diagnostics and treatment monitoring.

Conclusion

Thin Film Pt100 Sensors have emerged as a cornerstone of precision temperature measurement in medical devices. Their combination of accuracy, rapid response, and durability makes them indispensable in a wide range of medical applications. As medical technology continues to advance, these sensors are poised to play an even more critical role in enabling new diagnostic and treatment modalities.

The ongoing development and refinement of Thin Film Pt100 Sensors promise to further enhance their capabilities, potentially revolutionizing patient care and medical research. For medical device manufacturers and healthcare providers looking to leverage the precision and reliability of these sensors, partnering with experienced manufacturers is crucial. To explore how Thin Film Pt100 Sensors can elevate the performance of your medical devices, reach out to our team of experts at sales11@xatzd.com.