Understanding Probe Type Thermistor Temperature Sensors

What are Probe Type Thermistor Temperature Sensors?

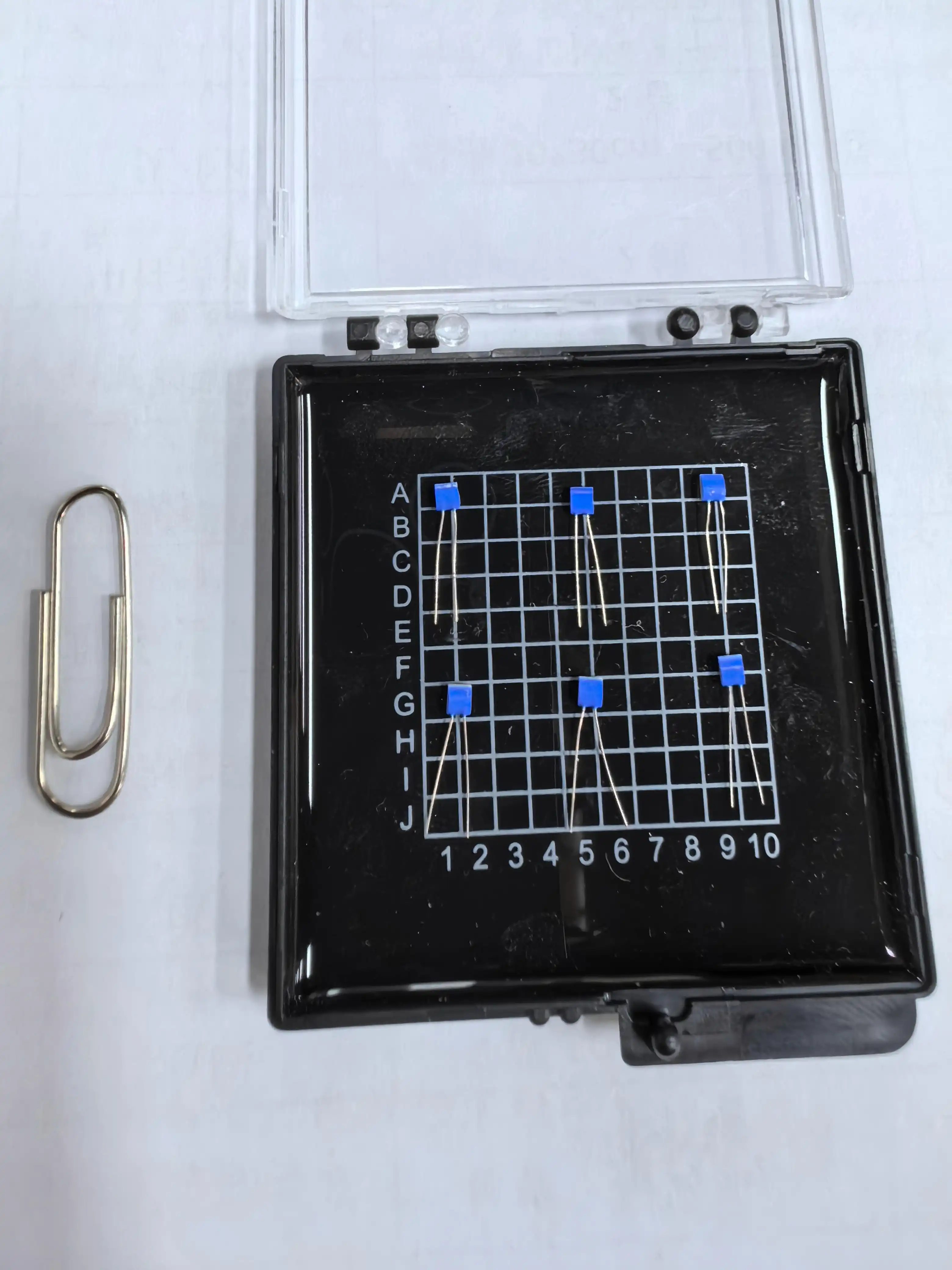

Probe type thermistor temperature sensors are specialized devices designed for accurate temperature measurement in various applications. These sensors consist of a thermistor element encased in a protective probe, offering robust performance and versatility. The thermistor, typically made of semiconductor materials like metal oxides, exhibits a significant change in electrical resistance as the temperature fluctuates.

The probe design allows for easy insertion into different mediums, making these sensors ideal for applications in industrial processes, HVAC systems, and scientific research. The probes can be customized in terms of length, diameter, and materials to suit specific requirements, enhancing their adaptability across diverse environments.

Key Features and Advantages

Probe type thermistor temperature sensors boast several advantageous features that set them apart in the world of temperature measurement. Their high sensitivity to temperature changes enables precise readings, often surpassing the accuracy of other sensor types. The compact size of the thermistor element allows for rapid response times, crucial in dynamic temperature monitoring scenarios.

These sensors also demonstrate excellent stability over time, ensuring consistent performance and reducing the need for frequent recalibration. Their wide temperature range capability, typically spanning from -55°C to 150°C for standard models, makes them suitable for a broad spectrum of applications. Additionally, the relatively low cost of thermistors compared to other temperature sensing technologies makes them an economical choice for many industries.

The Science Behind Resistance-to-Temperature Conversion

Thermistor Characteristics and Behavior

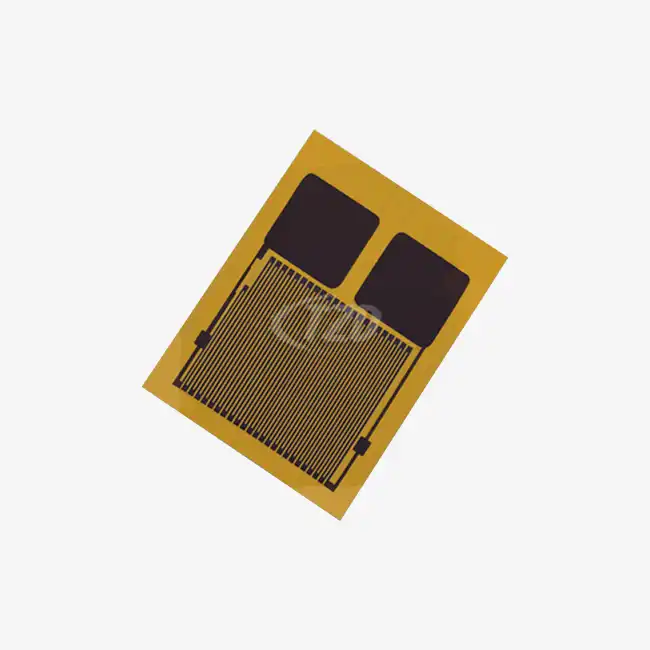

The fundamental principle underlying probe type thermistor temperature sensors is the temperature-dependent resistance of the thermistor material. Most thermistors exhibit a negative temperature coefficient (NTC), meaning their resistance decreases as temperature increases. This relationship between temperature and resistance is highly non-linear, following a complex exponential curve.

The behavior of a thermistor can be described by the Steinhart-Hart equation, a mathematical model that provides a precise relationship between temperature and resistance. This equation takes into account the unique characteristics of each thermistor, allowing for accurate temperature calculations across a wide range.

Signal Conditioning and Processing

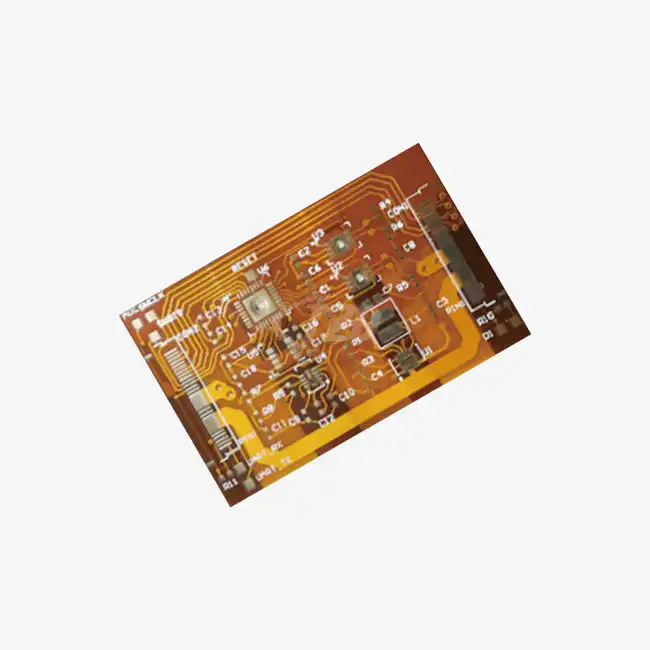

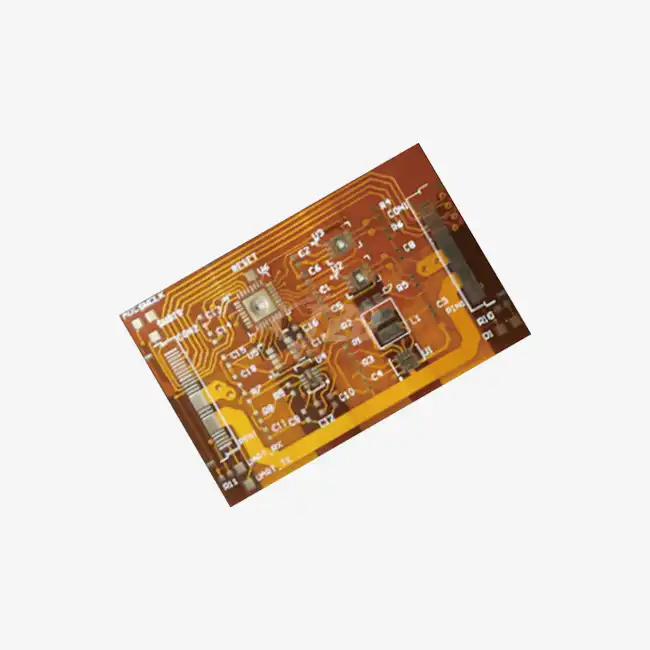

Converting the resistance change of a thermistor into usable temperature data requires sophisticated signal conditioning and processing techniques. Initially, the resistance change is converted into a voltage signal using a Wheatstone bridge circuit or a simple voltage divider. This voltage signal is then amplified to a level suitable for further processing.

Analog-to-digital converters (ADCs) play a crucial role in transforming the analog voltage signal into digital data that can be interpreted by microcontrollers or other digital systems. High-resolution ADCs ensure that even small temperature changes are accurately captured, contributing to the overall precision of the measurement system.

To address the non-linear nature of thermistor behavior, linearization techniques are often employed. These can be implemented through hardware circuits or, more commonly, through software algorithms. Polynomial approximation methods or look-up tables are used to convert the raw resistance or voltage readings into accurate temperature values.

Advanced Applications and Future Trends

Industrial and Scientific Applications

Probe type thermistor temperature sensors find extensive use in various industrial and scientific applications due to their accuracy and versatility. In the manufacturing sector, these sensors play a crucial role in monitoring and controlling process temperatures, ensuring product quality and consistency. They are particularly valuable in industries such as food processing, pharmaceuticals, and chemical manufacturing, where precise temperature control is paramount.

In scientific research, probe type thermistor temperature sensors are indispensable tools for experiments requiring accurate temperature measurements. They are used in laboratory equipment, environmental monitoring systems, and even in space exploration missions. The ability to customize probe designs allows researchers to adapt these sensors to specific experimental setups, enhancing the quality and reliability of their data collection.

Emerging Technologies and Integration

The field of temperature sensing is continuously evolving, with probe type thermistor temperature sensors at the forefront of innovation. Recent advancements include the development of ultra-miniature thermistors, enabling temperature measurements in previously inaccessible locations. These micro-sized sensors are finding applications in medical devices, wearable technology, and IoT (Internet of Things) devices.

Integration of thermistor sensors with wireless communication technologies is another growing trend. This allows for remote temperature monitoring and data logging, eliminating the need for wired connections and enabling real-time temperature tracking across vast areas or in challenging environments.

Moreover, the incorporation of artificial intelligence and machine learning algorithms is enhancing the capabilities of thermistor-based temperature measurement systems. These advanced techniques enable predictive maintenance, anomaly detection, and improved accuracy through adaptive calibration methods.

Conclusion

Probe type thermistor temperature sensors represent a culmination of precision engineering and advanced materials science. Their ability to convert resistance changes into accurate, measurable temperature data has made them indispensable in numerous applications across industries. As technology continues to advance, these sensors are likely to become even more sophisticated, offering higher accuracy, faster response times, and seamless integration with digital systems.

For those seeking cutting-edge temperature sensing solutions, Xi'an Tongzida Technology Co., Ltd. stands at the forefront of sensor innovation. With our expertise in thin film temperature sensitive chip design and manufacturing, we offer a range of high-performance temperature sensors suitable for diverse applications. To explore how our advanced sensor technologies can benefit your projects, please contact us at sales11@xatzd.com.