Grasping Battery Pack Temperature Sensors

Battery pack temperature sensors play an urgent part in guaranteeing the secure and productive operation of vitality capacity frameworks. These sensors are designed to monitor the temperature fluctuations within battery packs, providing critical data for battery management systems (BMS) to maintain optimal performance and prevent potential hazards.

Types of Temperature Sensors Used in Battery Packs

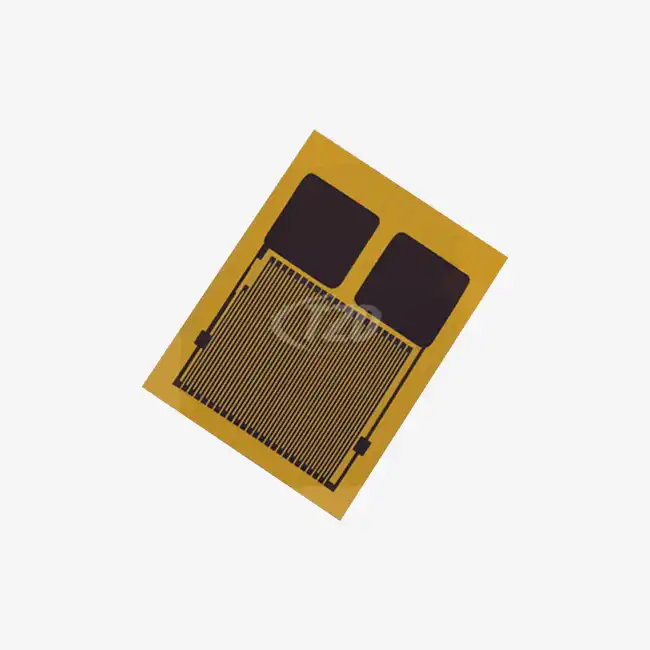

Different sorts of temperature sensors are utilized in battery packs, each with its one of a kind characteristics and focal points. Thermistors, resistance temperature detectors (RTDs), and thermocouples are among the most commonly used sensors. Thermistors offer high sensitivity and rapid response times, making them ideal for detecting subtle temperature changes. RTDs, such as thin film platinum resistors, provide exceptional accuracy and stability over a wide temperature range. These sensors, complying with the IEC60751 standard, can measure temperatures from -200°C to +850°C with remarkable precision.

Importance of Accurate Temperature Monitoring in Battery Packs

Precise temperature checking is vital for battery pack security and life span. Overheating can lead to thermal runaway, possibly causing fires or explosions. Conversely, extremely low temperatures can significantly reduce battery capacity and performance. By continuously monitoring temperature through the battery pack temperature sensor, battery management systems can implement protective measures such as adjusting charging rates, activating cooling systems, or shutting down the battery pack if necessary.

Integration of Temperature Sensors in Battery Management Systems

Temperature sensors are indispensably components of progressed battery administration frameworks. These frameworks utilize sensor information to optimize charging calculations, adjust cell voltages, and assess the state of charge and state of wellbeing of the battery pack. The integration of high-precision sensors, such as those with a temperature coefficient of 3850ppm/°C and an accuracy of ±0.01 Ω, enables battery management systems to make informed decisions, enhancing overall system efficiency and reliability.

Methods to Test Temperature Sensor Functionality

Guaranteeing the legitimate working of temperature sensors is basic for keeping up the security and productivity of battery packs. Several methods can be employed to test and verify sensor functionality, ranging from simple visual inspections to more advanced techniques using specialized equipment.

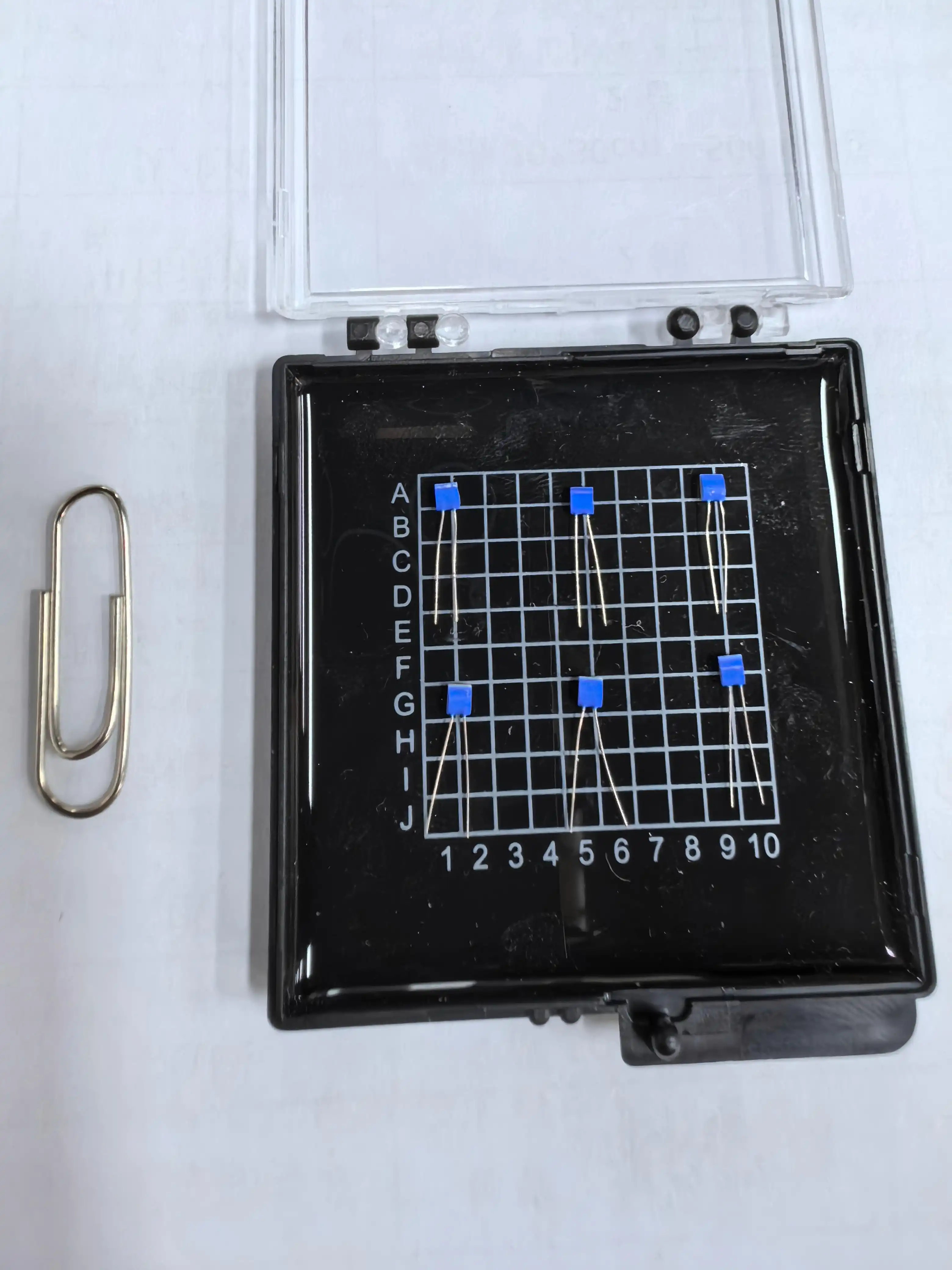

Visual Inspection and Physical Checks

The first step in assessing a temperature sensor's condition is a thorough visual inspection. Look for signs of physical damage, corrosion, or loose connections that could affect sensor performance. Pay close attention to the sensor's mounting and any protective coatings or enclosures. For sensors with lead materials like platinum nickel, silver nickel, or pure platinum, ensure the connections are secure and free from oxidation.

Resistance Measurement Using a Multimeter

For resistive temperature sensors like thermistors and RTDs used in battery pack temperature sensing, measuring resistance with a multimeter can provide important insights into their functionality. Disconnect the battery pack temperature sensor from the battery management system and measure its resistance at room temperature. Compare this value with the manufacturer's specifications. For platinum resistors with a temperature coefficient of 3850 ppm/°C, you can calculate the expected resistance change for a given temperature difference and verify if the sensor responds accordingly.

Temperature Simulation and Response Testing

To evaluate a sensor's dynamic response, you can simulate temperature changes and observe its behavior. This can be done using a calibrated heat source or a temperature chamber. Gradually increase and decrease the temperature while monitoring the sensor's output. High-quality sensors, like those with a reaction time of up to 0.05 seconds, ought to rapidly and precisely reflect temperature changes. This method is particularly effective for assessing the sensor's performance across its entire operating range, which can be as wide as -200°C to +850°C for some advanced thin film platinum resistors.

Comparative Testing with Known Good Sensors

Another effective method is to compare the readings of the suspect sensor with those of a known good sensor or a calibrated reference thermometer. Place both sensors in the same thermal environment and compare their outputs. Any significant discrepancies may indicate a problem with the sensor under test. This strategy is particularly valuable for recognizing sensors that have floated out of calibration over time, as it can identify indeed little deviations that might not be clear in other tests.

Troubleshooting Common Temperature Sensor Issues

When working with battery pack temperature sensors, different issues can emerge that influence their execution and unwavering quality. Understanding these common problems and their solutions is essential for maintaining the integrity of battery management systems.

Identifying and Resolving Wiring and Connection Problems

Faulty wiring or loose connections are frequent culprits behind temperature sensor malfunctions. Inspect all wiring for signs of wear, fraying, or damage. Ensure that all connections are tight and free from corrosion. For sensors with specialized lead materials, such as platinum nickel or silver nickel, verify that the connections are compatible and properly terminated. In high-vibration environments, like automotive applications, check that the sensor's mounting is secure, as sensors with vibration resistance up to 40g and impact resistance of 100g are designed to withstand such conditions.

Addressing Sensor Drift and Calibration Issues

Over time, temperature sensors may experience drift, leading to inaccurate readings. Regular calibration is crucial to maintain sensor accuracy. For high-precision sensors with long-term stability drift ≤ 0.04%, less frequent calibration may be required, but it's still essential to verify their performance periodically. Calibration can be performed using precision temperature sources or by comparing the sensor's output to that of a certified reference thermometer across its operating range.

Dealing with Environmental Factors Affecting Sensor Performance

Environmental conditions can significantly impact sensor performance. Extreme temperatures, humidity, electromagnetic interference, and chemical exposure can all affect sensor accuracy and longevity. When troubleshooting, consider the sensor's operating environment and whether it matches the sensor's specifications. For instance, sensors designed for high-demand scenarios like aerospace applications may have different environmental tolerances compared to those used in consumer electronics.

Replacing Faulty Sensors and Ensuring System Compatibility

When a temperature sensor is determined to be faulty beyond repair or calibration, replacement is necessary. When selecting a substitution sensor, guarantee it meets or surpasses the details of the unique, counting temperature extend, precision, and reaction time. For critical applications, consider upgrading to sensors with advanced features, such as those complying with the IEC60751 standard or offering customizable sizes ranging from 1.2mm to 4.0mm. After replacement, verify the new sensor's compatibility with the existing battery management system and recalibrate if necessary to ensure optimal performance.

Conclusion

Ensuring the proper functioning of battery pack temperature sensors is crucial for the safety and efficiency of energy storage systems. By employing a combination of visual inspections, electrical measurements, and performance tests, you can effectively verify sensor functionality and address potential issues promptly. Regular maintenance and calibration of these sensors contribute to the overall reliability and longevity of battery packs across various applications, from consumer electronics to industrial and aerospace systems. For more information on advanced temperature sensing solutions and custom sensor options, please contact us at sales11@xatzd.com.