- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How accurate is thin film PT100 sensor?

Thin Film Pt100 Sensors are renowned for their exceptional accuracy in temperature measurement. These sensors, compliant with the IEC60751 standard, boast an impressive accuracy of ±0.01 Ω. This translates to a temperature measurement precision of approximately ±0.026°C at 0°C. The high accuracy is attributed to the sensor's stable temperature coefficient of 3850 ppm/°C and its remarkable long-term stability, with a resistance drift of ≤±0.04% after 1000 hours at 500°C. This level of precision makes Thin Film Pt100 Sensors ideal for applications requiring exact temperature readings across a wide range from -200°C to +850°C.

The Technology Behind Thin Film Pt100 Sensors

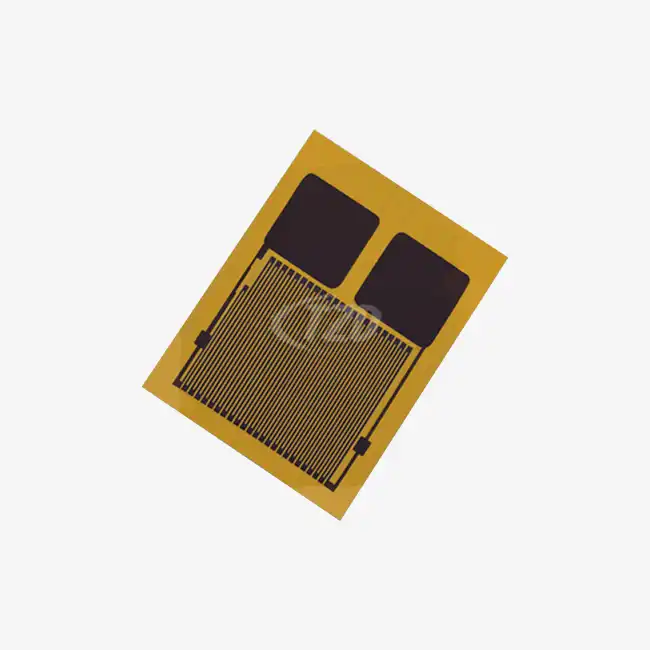

Thin Film Pt100 Sensors represent a pinnacle in temperature measurement technology. These sensors are fabricated using advanced thin-film deposition techniques, which allow for precise control over the sensor's physical and electrical properties. The sensing element consists of a thin layer of platinum deposited on a ceramic substrate, typically measuring between 1.2mm and 2.3mm in length and width, with a thickness of about 1.0mm.

The platinum layer, being the active sensing element, is carefully engineered to achieve a resistance of 100 ohms at 0°C, hence the designation "Pt100". This resistance changes predictably with temperature, following a well-defined relationship. The temperature coefficient of resistance (TCR) for these sensors is 3850 ppm/°C, which means for every degree Celsius change in temperature, the resistance changes by 0.385 ohms.

One of the key advantages of thin film technology is the ability to create extremely small and uniform sensing elements. This miniaturization not only allows for faster response times but also enhances the sensor's ability to measure temperature accurately in confined spaces or rapidly changing environments. The small size contributes to the sensor's impressive response time, with t0.5 (time to reach 50% of the final value) as low as 0.05 seconds in flowing conditions.

Precision in Manufacturing

The manufacturing process of Thin Film Pt100 Sensors involves several high-precision steps. The platinum film is deposited under carefully controlled conditions to ensure uniformity and the correct thickness. This is followed by laser trimming to achieve the exact resistance value at the reference temperature. The precision in manufacturing is crucial for maintaining the tight tolerances required for high accuracy.

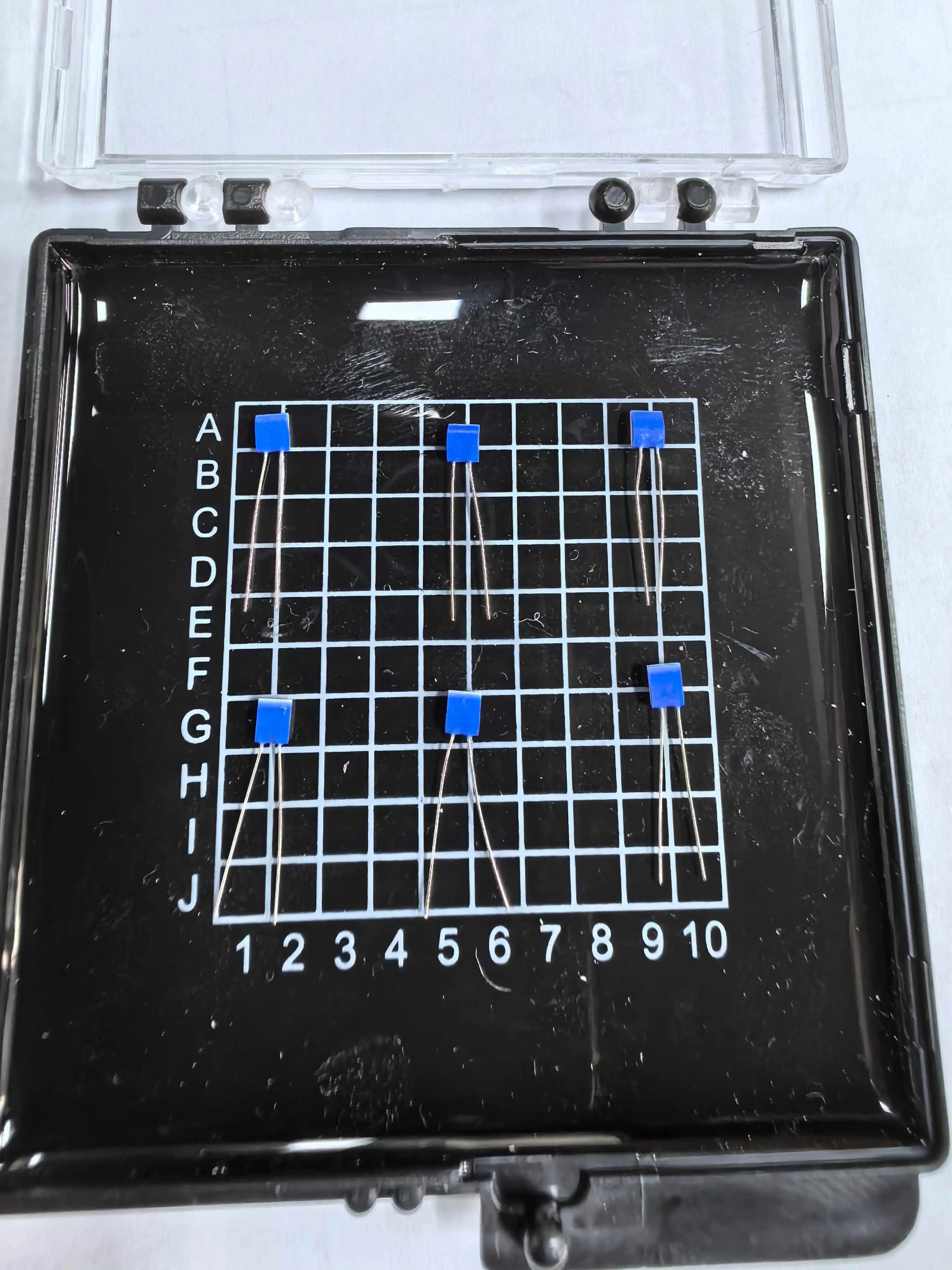

The leads attached to the sensing element are typically made of platinum-nickel wire, although other materials like silver-palladium or pure platinum can be used depending on the application. These leads, usually 10mm in length and 0.2mm in diameter, are designed to minimize heat conduction away from the sensing element, which could otherwise affect the accuracy of the measurements.

Factors Influencing the Accuracy of Thin Film Pt100 Sensors

While Thin Film Pt100 Sensors are inherently accurate, several factors can influence their performance in real-world applications. Understanding these factors is crucial for maintaining the sensor's high accuracy across various operating conditions.

Self-Heating Effects

One of the primary considerations in using Thin Film Pt100 Sensors is the self-heating effect. When current passes through the sensor to measure its resistance, it generates a small amount of heat. This self-heating can cause a slight increase in the sensor's temperature, potentially leading to measurement errors. The self-heating coefficient for these sensors is typically around 0.4°C/mW. To mitigate this effect, it's crucial to use an appropriate operating current, usually between 0.3 and 1 mA, balancing the need for a strong signal with minimal self-heating.

Environmental Factors

Environmental conditions can significantly impact the accuracy of Thin Film Pt100 Sensors. Vibration and shock can affect the sensor's performance, although these sensors are designed to withstand considerable mechanical stress. The specifications typically indicate vibration resistance of ≥40g acceleration in the 10 to 2000 Hz frequency range and shock resistance of ≥100g acceleration for an 8 ms half-sine wave.

Humidity and corrosive atmospheres can also affect the sensor's long-term stability. While the platinum element itself is highly resistant to corrosion, the leads and connections may be vulnerable. This is why proper packaging and installation are crucial. Many sensors come in vacuum plastic packaging to protect them during storage and transport.

Calibration and Compensation

To maintain high accuracy, regular calibration of Thin Film Pt100 Sensors is essential. While these sensors have excellent long-term stability (≤±0.04% resistance drift after 1000 hours at 500°C), periodic calibration ensures that any drift is detected and corrected. Additionally, in applications where the highest precision is required, compensation techniques can be employed to account for lead resistance and other systematic errors.

Applications Leveraging the Accuracy of Thin Film Pt100 Sensors

The high accuracy of Thin Film Pt100 Sensors makes them invaluable in a wide range of applications where precise temperature measurement is critical. These sensors find extensive use in industries such as aerospace, automotive, medical, and industrial process control.

Industrial Process Control

In industrial settings, Thin Film Pt100 Sensors play a crucial role in maintaining precise temperature control in various processes. Their ability to provide accurate readings over a wide temperature range (-200°C to +850°C) makes them ideal for applications in chemical processing, food and beverage production, and pharmaceutical manufacturing. The sensors' fast response time (as low as 0.05 seconds in flowing conditions) allows for rapid detection of temperature changes, enabling quick adjustments in process control systems.

Medical and Laboratory Applications

The medical field relies heavily on the accuracy of Thin Film Pt100 Sensors for applications such as patient monitoring, medical equipment, and laboratory research. In these settings, even small temperature variations can have significant implications. The sensors' high accuracy and stability ensure reliable temperature measurements in critical applications like incubators, blood analyzers, and sterilization equipment.

Aerospace and Automotive Industries

In aerospace and automotive applications, Thin Film Pt100 Sensors are used for monitoring engine temperatures, environmental control systems, and fuel systems. The sensors' ability to withstand high vibration (≥40g acceleration) and shock (≥100g acceleration) makes them suitable for these demanding environments. Their compact size (as small as 1.2mm x 2.0mm x 1.0mm) allows for integration into tight spaces without compromising on accuracy.

The versatility and accuracy of Thin Film Pt100 Sensors continue to drive their adoption across various industries. As technology advances, we can expect to see even more innovative applications leveraging the precision of these remarkable sensors.

Conclusion

Thin Film Pt100 Sensors represent a pinnacle in temperature measurement technology, offering exceptional accuracy, stability, and versatility. Their ability to provide precise measurements across a wide temperature range, coupled with their compact size and robust construction, makes them indispensable in numerous high-demand applications. As industries continue to evolve and demand ever-greater precision, the role of these sensors in ensuring accurate temperature control and monitoring will only grow in importance.

For those seeking to leverage the accuracy and reliability of Thin Film Pt100 Sensors in their applications, it's crucial to partner with experienced manufacturers who understand the intricacies of sensor design and production. If you're looking for more information or have specific requirements for your temperature sensing needs, don't hesitate to reach out to industry experts. You can contact us at sales11@xatzd.com for personalized guidance and solutions tailored to your unique temperature measurement challenges.

References

1. McGee, T. D. (2018). Principles and Methods of Temperature Measurement. John Wiley & Sons.

2. Childs, P. R. N. (2001). Practical Temperature Measurement. Butterworth-Heinemann.

3. Michalski, L., Eckersdorf, K., Kucharski, J., & McGhee, J. (2001). Temperature Measurement. John Wiley & Sons.

4. Baker, B. (2011). Temperature Sensing Technologies. AN679, Microchip Technology Inc.

5. Kerlin, T. W., & Johnson, M. (2012). Practical Thermocouple Thermometry. Instrument Society of America.

Learn about our latest products and discounts through SMS or email