- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How to achieve ± 0.2 ℃ consistency in TCR3750 thin film platinum resistance?

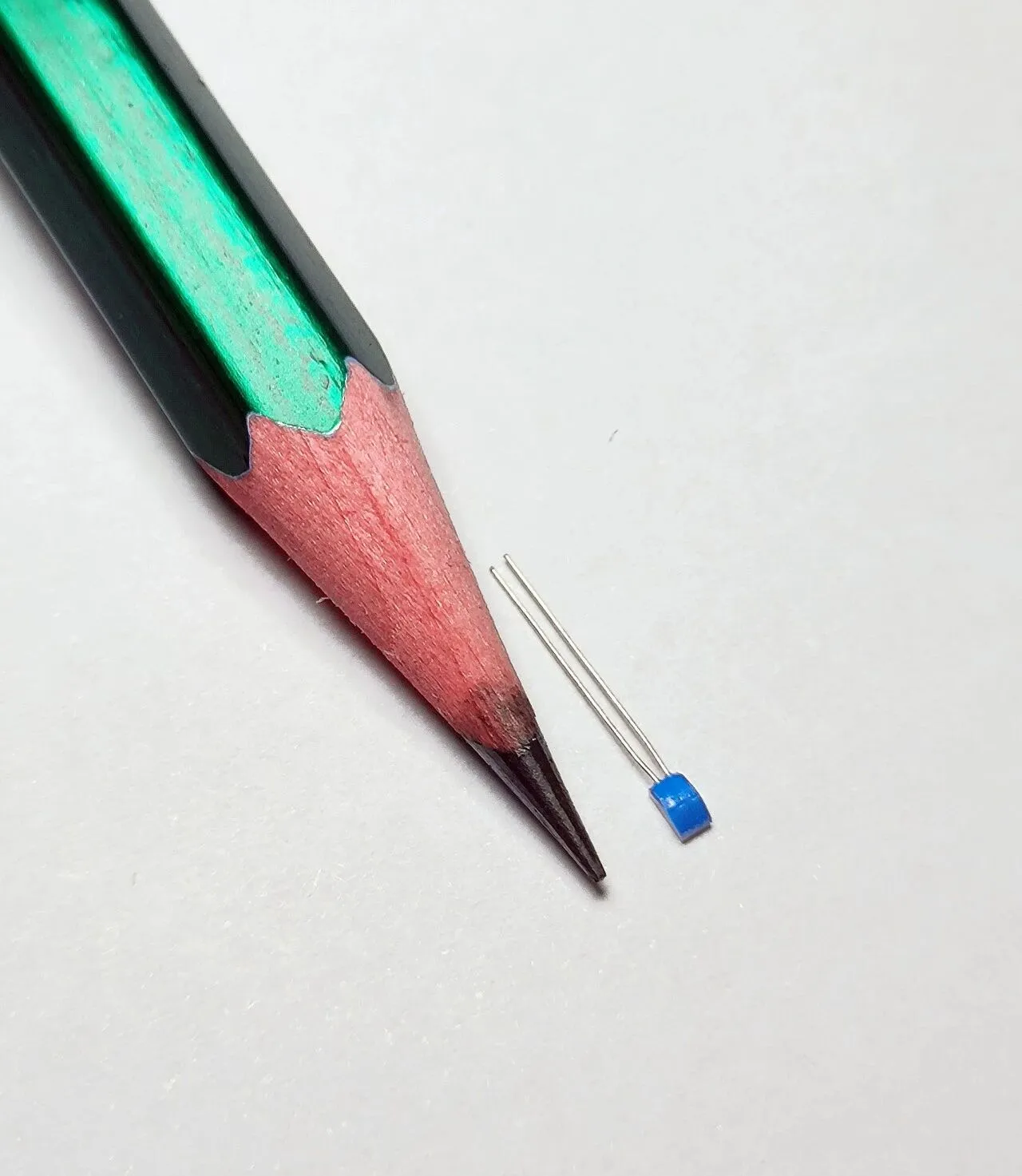

Is the temperature measurement of multiple workstations on the industrial production line not synchronized? How to achieve ± 0.2 ℃ consistency in TCR3750 thin film platinum resistance?

In the scenarios of multi-stage temperature control (± 0.5 ℃) of injection molding machine barrel, reflow soldering furnace temperature curve (± 1 ℃), and heat treatment furnace temperature uniformity (± 2 ℃), precision temperature measurement thin film platinum resistors on industrial production lines solve product defects caused by traditional sensor multi station synchronization errors (>± 1 ℃) with "batch consistency+oil pollution protection"

H2: Two efficiency killers for temperature measurement in industrial production lines

H3: Multi station synchronization error: Traditional sensor batch tolerance ± 1%, maximum deviation of temperature measurement at 10 stations ± 2 ℃, resulting in shrinkage of injection molded parts/reflow soldering virtual welding;

H3: Oil pollution environment failure: Oil pollution on the production line (such as injection molding oil, flux) penetrates the sensor packaging, with a short circuit rate of 20% per year and frequent downtime for maintenance.

H2: Production line advantages of TCR3750 thin film platinum resistance

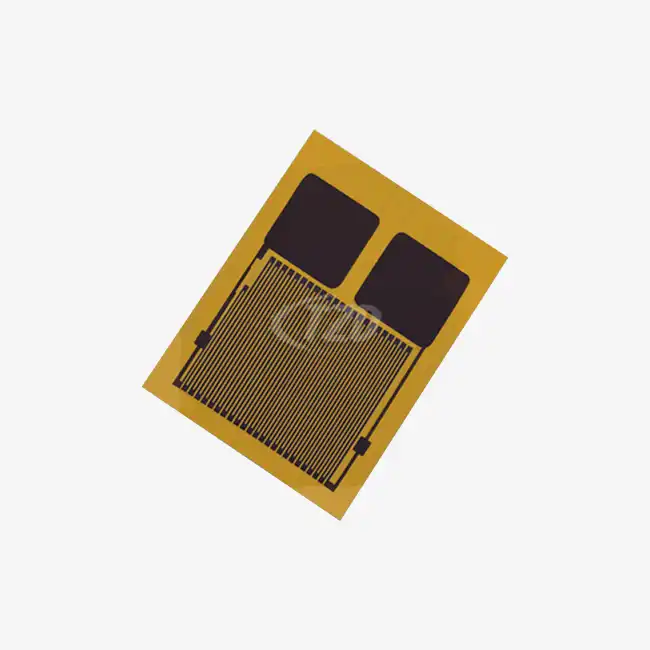

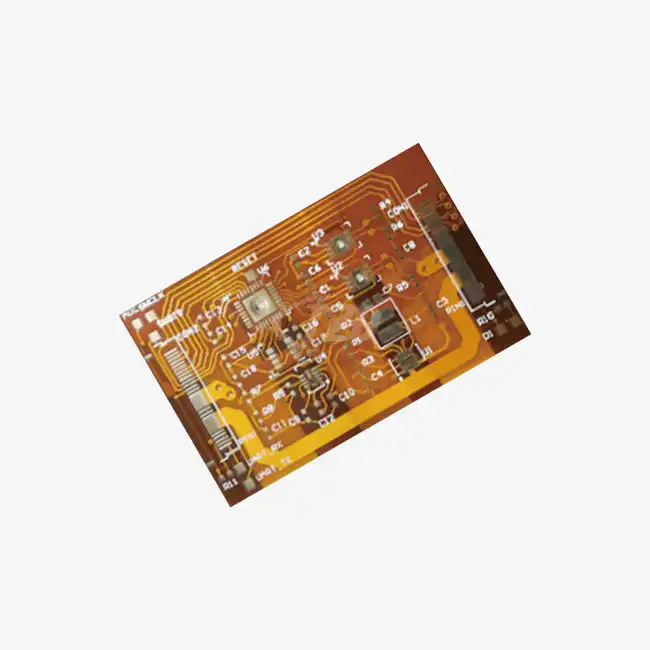

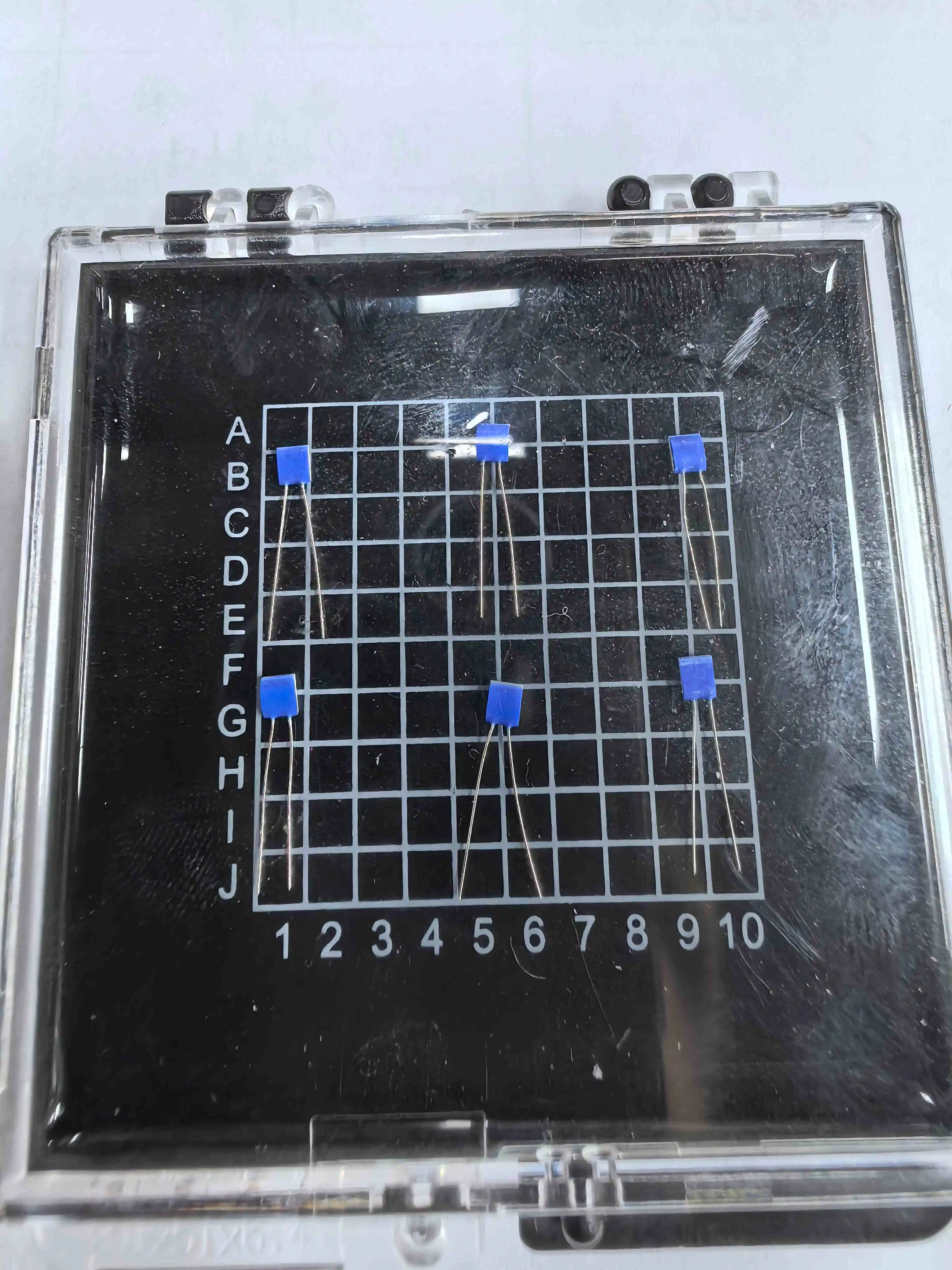

Our industrial production line precision temperature measurement thin film platinum resistors have a resistance tolerance of ± 0.2% (industry average ± 1%) for the entire batch, with a maximum deviation of<± 0.3 ℃ for synchronous temperature measurement at 10 workstations. Combined with a multi-point acquisition system, we achieve "one click parameter adjustment" for the production line.

H3: Oil pollution protection: using fluororubber sealing rings and nano oil repellent coatings, passing a 72 hour oil pollution immersion test (resistance change<0.1%), with a lifespan of>5 years;

After being used by a certain automotive parts factory, the defect rate of injection molded parts decreased from 3% to 0.5%, saving an annual rework cost of 5 million yuan. This is precisely the value of precision temperature measurement thin film platinum resistors in industrial production lines.

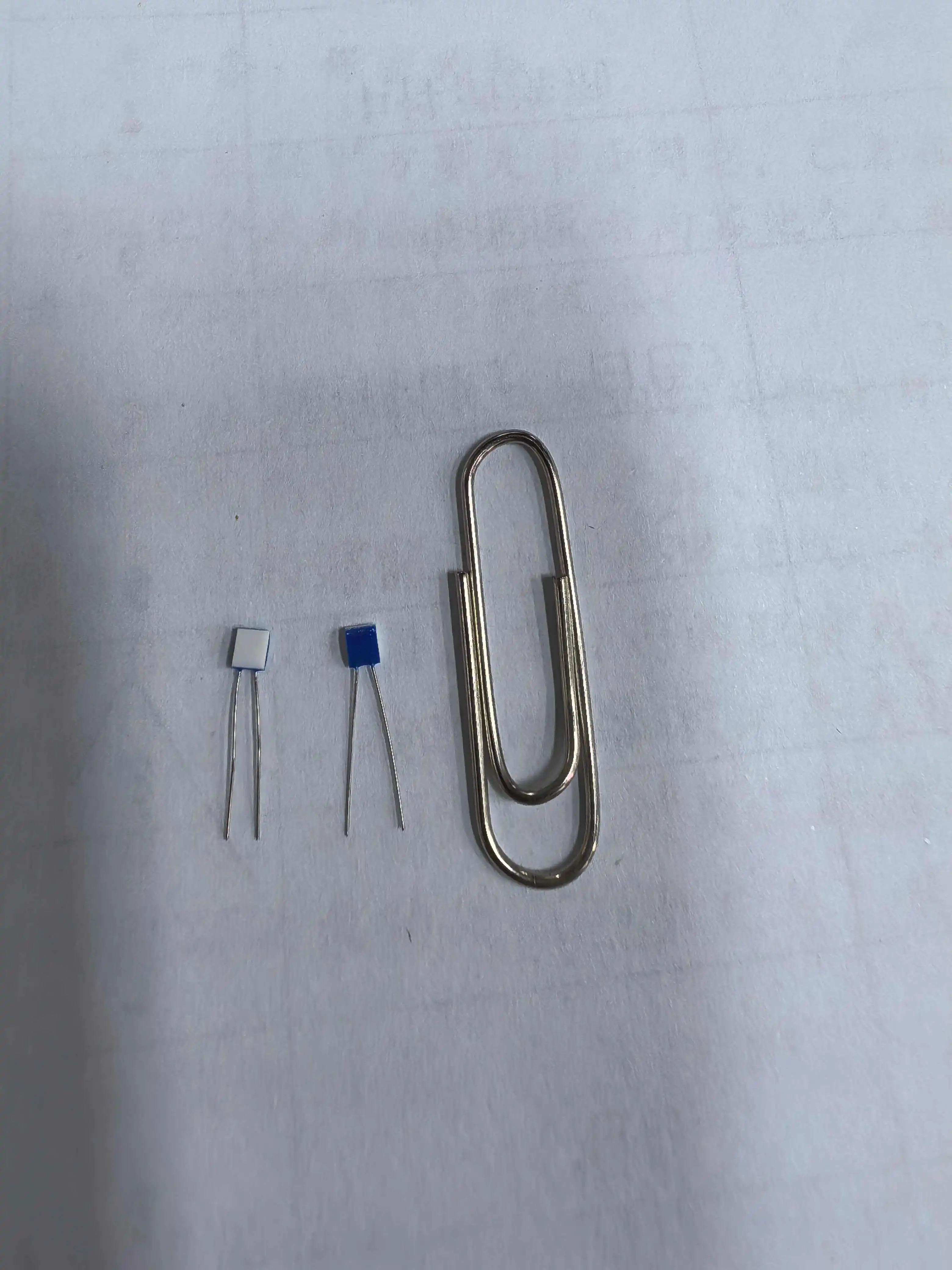

H3: Quick replacement: snap on installation (no welding required), single sensor replacement time<5 minutes (traditional welding takes 30 minutes).

H2: Practical case: Temperature control upgrade of injection molding machine in a certain automotive parts factory

Scenario: A 2000 ton injection molding machine from a certain factory (with 5-stage temperature control of the material barrel, requiring synchronous monitoring of the temperature of the molten plastic at 200-300 ℃)

Solution: Customized 5 × 3mm PT100 thin film platinum resistance (snap on installation on each section of the material barrel)+PLC centralized acquisition

Effect: Multi stage temperature control synchronization error ± 0.3 ℃, injection molded part size tolerance compliance rate increased from 92% to 99.5%, and production capacity increased by 15%.

H2: Selection Guide: 4 Key Points for Industrial Line Sensors

Batch consistency (± 0.2% resistance tolerance, priority given to fully inspected batches)

Protection level (IP65 oil proof, suitable for workshop environment)

Installation method (snap/thread optional, quick replacement)

Certification (IATF16949 Automotive Supply Chain+CE)

References (3):

Specification for Temperature Monitoring of Industrial Automation Production Lines (JB/T 10221-2013)

Report on Injection Molding Machine Upgrade at a Certain Automotive Parts Factory (2024)

SGS Oil Pollution Protection Test Report (Report No. TJ-SGS-02412)

Making the temperature measurement on the industrial production line "neat and uniform", the precision temperature measurement film platinum resistance on the industrial production line is a multiplier of efficiency and yield. Leave a message in the comment section for "consultation" and get the same car factory solution for free!

Author Information: Mr. Zhao | Industrial Automation Sensor Product Manager (12 years of experience in thermal management of automotive production lines, leading the renovation of over 20 factories)

FAQ (3 questions):

Q1: Can the sensor withstand high-frequency vibrations on the production line (such as punching machines)?

A: Through 10G high-frequency vibration testing (20~2000Hz), there are no pin breakage/accuracy drift.

Q2: Does it support Profinet/EtherCAT industrial protocol?

A: Provide protocol conversion gateway for seamless integration with Siemens/Mitsubishi PLC.

Q3: Is there a price ladder for bulk procurement?

A: The unit price for orders over 10000 pieces will decrease by 15%, and for orders over 100000 pieces, it will decrease by 25% (long-term cooperation is better).

Xi'an Tongzida Technology Co., Ltd. est un fabricant et fournisseur de premier plan de technologies de thermistance avancées, spécialisé dans la fourniture de capteurs de température haute performance pour les applications industrielles exigeantes. Notre expertise approfondie en matière de fabrication de microcapteurs, de technologies d'encapsulation spéciales et de méthodes d'intégration multi-capteurs nous permet de garantir l'excellente performance et la fiabilité de nos thermistances. En tant que fournisseur de confiance de solutions de mesure de température de précision, nous proposons un système complet de thermistances, incluant les puces sensibles, les systèmes de test et les logiciels d'analyse. N'hésitez pas à contacter nos experts techniques. ventes11@xatzd.com Discutez de vos besoins spécifiques en matière de thermistances et découvrez comment nos capacités avancées d'optimisation et de fabrication de résistances en température peuvent améliorer les performances et la fiabilité de votre système de mesure de température.

Learn about our latest products and discounts through SMS or email