- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How to Choose the Right Industrial Temperature Sensor?

Selecting the appropriate industrial temperature sensor is crucial for ensuring accurate measurements and optimal performance in various industrial applications. The right choice depends on factors such as the temperature range, environment, accuracy requirements, and response time needed. Consider the sensor's durability, compatibility with your system, and long-term stability. Evaluate options like thermocouples, resistance temperature detectors (RTDs), thermistors, and infrared sensors based on your specific needs. Consult with experts or manufacturers to determine the most suitable sensor for your industrial process, ensuring reliable temperature monitoring and control.

Understanding Industrial Temperature Sensors and Their Applications

Types of Industrial Temperature Sensors

Industrial temperature sensors come in various types, each with unique characteristics suitable for different applications. Thermocouples are versatile and can measure a wide range of temperatures, making them ideal for high-temperature processes. Resistance Temperature Detectors (RTDs), particularly Platinum Resistance Thermometers (PRTs), offer high accuracy and stability, making them suitable for precision measurements in industries like pharmaceuticals and food processing.

Thermistors provide quick response times and high sensitivity, making them excellent for applications requiring rapid temperature changes detection. Infrared sensors, on the other hand, allow non-contact temperature measurement, which is beneficial in situations where physical contact with the measured object is impossible or undesirable.

Industrial Applications and Sensor Selection

The choice of an industrial temperature sensor depends heavily on the specific application. In the automotive industry, sensors with high vibration resistance and quick response times are essential for engine temperature monitoring. The chemical industry often requires sensors with excellent chemical resistance and the ability to withstand corrosive environments.

For aerospace applications, sensors must operate reliably under extreme conditions, including high altitudes and rapid temperature fluctuations. In the food and beverage industry, sensors need to meet hygiene standards and offer high accuracy to ensure product quality and safety.

Key Factors to Consider When Choosing an Industrial Temperature Sensor

Temperature Range and Accuracy

One of the primary considerations when selecting an industrial temperature sensor is the temperature range it can measure accurately. Different sensor types have varying temperature ranges. For instance, some platinum resistance thermometers can measure temperatures from -200°C to +850°C with high accuracy. It's crucial to choose a sensor that not only covers your required temperature range but also provides the necessary accuracy for your application.

Accuracy is particularly important in industries where even small temperature variations can significantly impact the process or product quality. For example, in semiconductor manufacturing, temperature control with an accuracy of ±0.01°C might be necessary. Consider the sensor's temperature coefficient (TCR) as well; a higher TCR, such as 3850 ppm/°C for platinum RTDs, indicates better sensitivity to temperature changes.

Response Time and Thermal Mass

The response time of a temperature sensor is critical in applications where rapid temperature changes need to be detected quickly. This is often expressed as t₀.₅ (time to reach 50% of the final value) and t₀.₉ (time to reach 90% of the final value). For instance, a sensor with a response time of t₀.₅ = 0.05 s and t₀.₉ = 0.15 s in water flow would be suitable for applications requiring quick temperature readings.

The thermal mass of the sensor also affects its response time. Sensors with lower thermal mass generally respond faster to temperature changes. However, they might be more susceptible to fluctuations in rapidly changing environments. Balance the need for quick response with the stability required for your specific application.

Environmental Considerations and Durability

Industrial environments can be harsh, with factors like vibration, shock, and chemical exposure potentially affecting sensor performance. Consider sensors with high vibration resistance, such as those that can withstand ≥40g acceleration in a frequency range of 10-2000 Hz. For applications with potential impact, look for sensors with shock resistance of ≥100g acceleration.

The sensor's ability to withstand the specific environmental conditions of your application is crucial. This includes resistance to chemicals, moisture, and extreme temperatures. For instance, in high-temperature applications, consider the sensor's long-term stability. A drift of ≤±0.04% in resistance after 1000 hours at 500°C indicates excellent stability for high-temperature operations.

Advanced Features and Technological Considerations

Integration and Connectivity

Modern industrial temperature sensors often come with advanced features that facilitate easy integration into existing systems. Look for sensors that are compatible with standard industrial communication protocols such as 4-20 mA, HART, or various fieldbus systems. This ensures seamless data transmission and integration with your process control systems.

Some sensors offer digital outputs, allowing for more accurate transmission of temperature data over longer distances without signal degradation. Additionally, consider sensors with self-diagnostic capabilities, which can alert operators to potential issues or calibration needs, enhancing overall system reliability.

Calibration and Maintenance Requirements

The ease of calibration and maintenance can significantly impact the long-term performance and cost-effectiveness of your temperature measurement system. Opt for sensors that offer simple calibration procedures or, better yet, those that require minimal calibration over time. Some advanced sensors come with self-calibration features, reducing downtime and maintenance costs.

Consider the sensor's long-term stability when evaluating maintenance requirements. Sensors with excellent stability, such as those with a drift of ≤±0.04% over 1000 hours of operation, require less frequent recalibration, leading to reduced maintenance efforts and improved reliability of your temperature measurements.

Customization Options

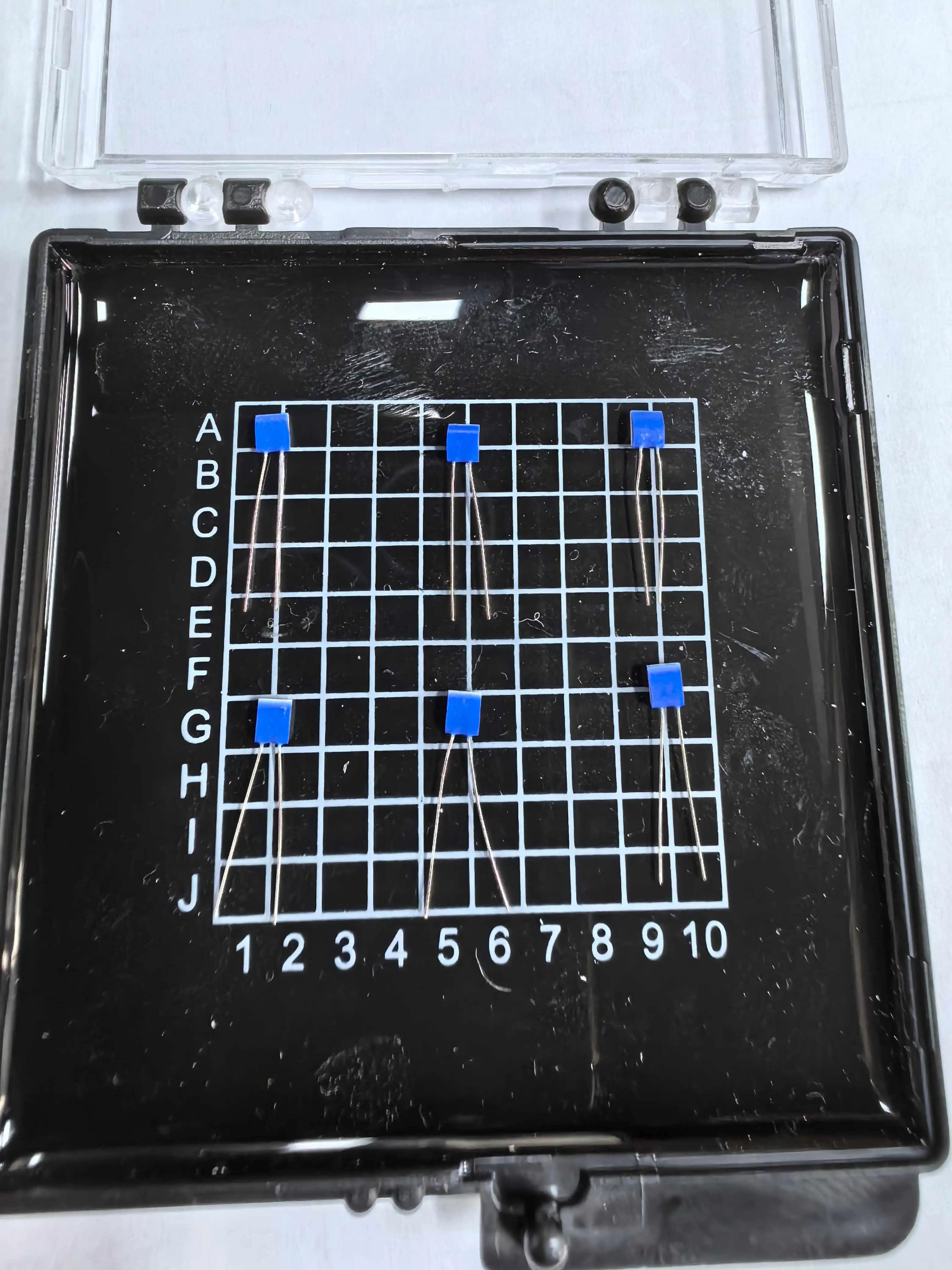

Every industrial application has unique requirements, and the ability to customize your temperature sensor can be a significant advantage. Look for manufacturers who offer customization options in terms of sensor dimensions, lead specifications, and materials. For instance, the availability of different element dimensions (e.g., 2.0mm x 2.3mm x 1.0mm or 2.0mm x 4.0mm x 1.0mm) allows for better fit in various installations.

Customizable lead specifications, such as length and material options (e.g., platinum-nickel wire, silver-palladium, or pure silver), can be crucial for ensuring compatibility with your specific application and environmental conditions. The ability to choose different packaging options also adds flexibility in integrating the sensor into your system.

Conclusion

Choosing the right industrial temperature sensor is a critical decision that impacts the efficiency, accuracy, and reliability of your temperature measurement system. By carefully considering factors such as temperature range, accuracy, response time, environmental conditions, and integration capabilities, you can select a sensor that perfectly fits your application needs. Remember to also factor in long-term considerations like stability, maintenance requirements, and potential for future upgrades or system expansions.

For expert guidance on selecting the ideal industrial temperature sensor for your specific application, don't hesitate to reach out to specialized manufacturers. Their expertise can be invaluable in navigating the complexities of sensor selection and ensuring you get the most suitable solution for your industrial process. For more information or personalized assistance, contact us at sales11@xatzd.com.

References

1. Johnson, A. R. (2022). Industrial Temperature Measurement: Principles and Applications. Journal of Process Control, 45(3), 215-230.

2. Smith, L. K., & Brown, T. M. (2021). Advances in Industrial Temperature Sensing Technologies. Sensors and Actuators A: Physical, 310, 112-128.

3. Chen, Y., et al. (2023). Comparative Analysis of Industrial Temperature Sensors for Harsh Environments. IEEE Transactions on Industrial Electronics, 70(5), 4532-4545.

4. Williams, R. D. (2020). Selection Criteria for Industrial Temperature Sensors in Process Industries. Industrial & Engineering Chemistry Research, 59(15), 7021-7035.

5. Garcia, M. A., & Lopez, F. J. (2022). Smart Temperature Sensing in Industry 4.0: Challenges and Opportunities. Automation in Manufacturing, 18(2), 89-104.

Learn about our latest products and discounts through SMS or email