Understanding Screw Type Thermal Resistance Temperature Sensors

Screw type thermal resistance temperature sensors are widely used in industrial and commercial applications due to their robustness and reliability. These sensors utilize the principle of electrical resistance change in certain materials, typically platinum, to measure temperature accurately. The screw-type design allows for easy installation and secure mounting in various equipment and processes.

Components and Construction

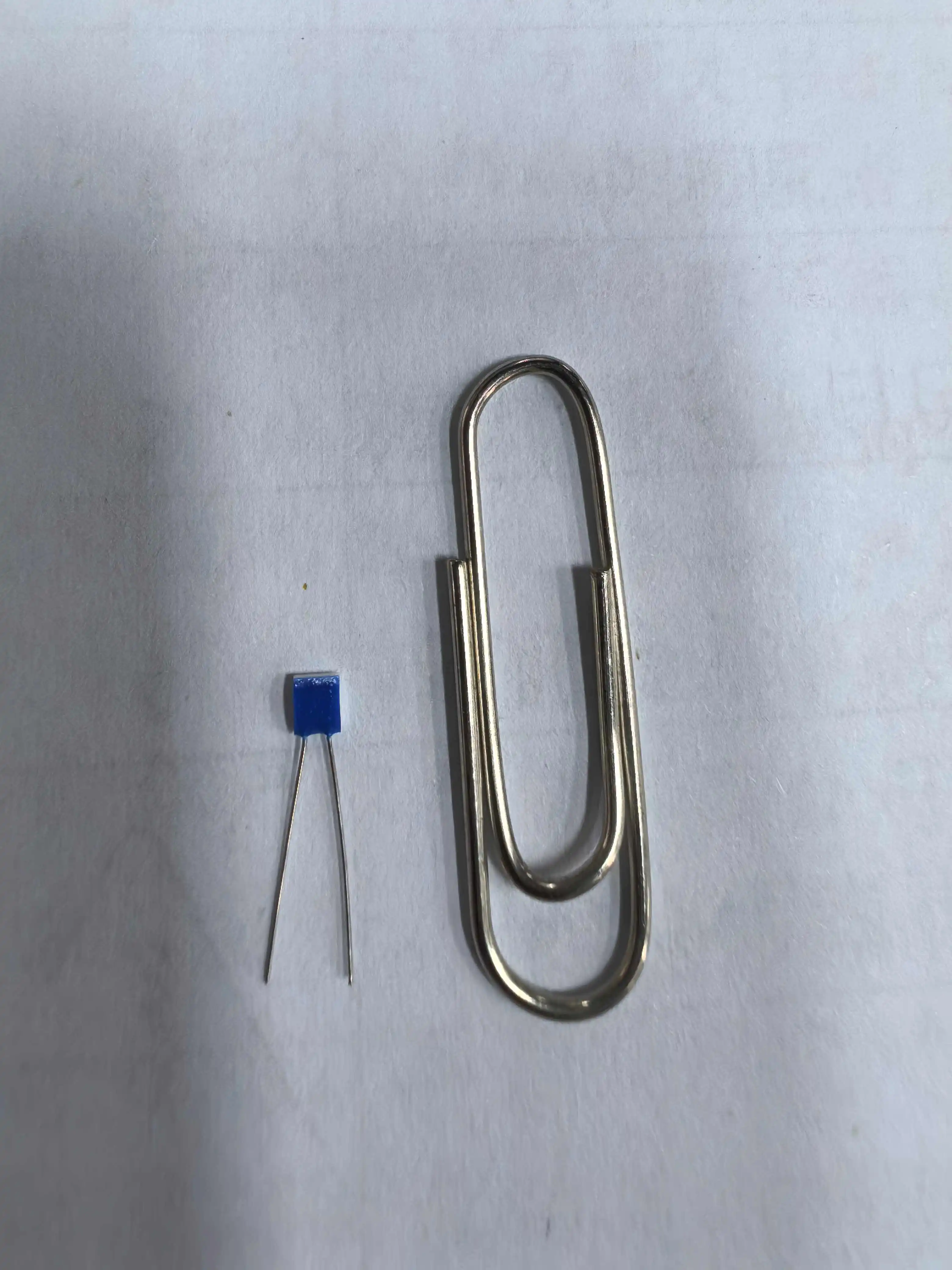

A typical screw type thermal resistance temperature sensor consists of several key components. The sensing element, often a thin film platinum resistor, is encased in a protective sheath. This sheath is attached to a threaded body, enabling convenient installation into threaded ports or thermowells. The sensor may incorporate various wire configurations, including two-wire, three-wire, or four-wire systems, each offering different levels of accuracy and compensation for lead wire resistance.

Operating Principles

The operating principle of these sensors relies on the predictable change in electrical resistance of the sensing element as temperature varies. For platinum-based sensors, this relationship is highly linear and repeatable, making them ideal for precise temperature measurements. The temperature coefficient, typically 3850 ppm/K for platinum sensors, defines the rate of resistance change per degree of temperature change.

Accuracy and Performance Factors

The accuracy of screw type thermal resistance temperature sensors depends on several factors. The sensor's accuracy class, such as Class A or Class B, determines the tolerance limits across different temperature ranges. For instance, a Class A sensor might have a tolerance of ±0.15°C in the range of -50°C to +300°C. Other factors affecting performance include self-heating effects, insulation resistance, and pressure resistance capabilities.

Common Issues and Failure Modes

Screw type thermal resistance temperature sensors, despite their durability, can experience various issues that affect their performance and accuracy. Understanding these common problems is essential for effective troubleshooting and maintenance.

Physical Damage and Environmental Factors

One of the primary causes of sensor failure is physical damage. This can occur due to improper handling during installation, exposure to excessive vibration, or impact from surrounding equipment. Environmental factors such as extreme temperatures, corrosive atmospheres, or high-pressure conditions can also lead to sensor deterioration over time. Regular visual inspections can help identify signs of external damage or corrosion that may compromise sensor integrity.

Electrical and Circuit-Related Problems

Electrical issues are another common source of sensor malfunction. These can include short circuits, open circuits, or insulation breakdown. Faulty wire connections, either at the sensor itself or in the connecting circuitry, can lead to erratic readings or complete sensor failure. Additionally, electromagnetic interference (EMI) from nearby equipment can introduce noise into the sensor signal, affecting measurement accuracy.

Calibration Drift and Aging Effects

Over time, resistance temperature sensors may experience calibration drift, where their resistance-temperature relationship gradually shifts from the original specifications. This drift can be caused by thermal cycling, contamination, or physical changes in the sensing element. Aging effects, particularly in sensors exposed to high temperatures or harsh environments, can lead to a gradual decrease in accuracy and responsiveness. Regular calibration checks and recalibration procedures are essential to maintain sensor accuracy throughout its operational life.

Diagnostic Techniques and Testing Methods

Effective diagnosis of screw type thermal resistance temperature sensors requires a systematic approach and appropriate testing methods. By employing these techniques, technicians can accurately determine the health and functionality of these critical sensing devices.

Resistance Measurement and Comparison

One of the fundamental diagnostic techniques involves measuring the sensor's resistance at a known temperature, typically room temperature, and comparing it to the manufacturer's specifications. This test can be performed using a precision multimeter. For instance, a Pt100 sensor should have a resistance of approximately 100 ohms at 0°C, with variations based on the specific temperature coefficient. Significant deviations from expected values may indicate sensor degradation or failure.

Insulation Resistance Testing

Insulation resistance testing is crucial for assessing the integrity of the sensor's electrical isolation. This test involves applying a high voltage (typically 500 V DC) between the sensor leads and its sheath or housing. The insulation resistance should be greater than or equal to 100 MΩ at 20°C for most high-quality sensors. Lower values may indicate moisture ingress or insulation breakdown, which can lead to measurement errors or safety hazards.

Temperature Response and Stability Checks

To evaluate a sensor's dynamic performance, temperature response tests can be conducted. This involves subjecting the sensor to controlled temperature changes and monitoring its output. A properly functioning sensor should respond quickly and consistently to temperature variations. Stability checks, where the sensor is held at a constant temperature for an extended period, can reveal issues with drift or noise in the sensor output. These tests are particularly important for applications requiring high accuracy and reliability.

Advanced Diagnostic Tools and Techniques

For more complex diagnostics, specialized tools and techniques may be employed. These can include thermal imaging cameras to detect hot spots or uneven temperature distribution in the sensor assembly, impedance analyzers for detailed electrical characterization, and data logging systems for long-term performance monitoring. In critical applications, comparative testing against calibrated reference sensors can provide additional confidence in sensor accuracy and reliability.

Conclusion

Maintaining the accuracy and reliability of screw type thermal resistance temperature sensors is crucial for many industrial and scientific applications. Regular testing and diagnostics can help identify issues early, ensuring consistent performance and preventing costly failures. For expert advice on temperature sensor selection, testing, or custom solutions, don't hesitate to contact us at sales11@xatzd.com. Our team of specialists is ready to assist you in optimizing your temperature measurement systems.