Introducing the Superiority of Platinum Resistance Temperature Sensors

The Science Behind Platinum's Thermal Properties

Platinum's unique thermal properties make it an ideal material for temperature sensing applications. Its resistance changes predictably and consistently with temperature, following a well-defined relationship. This characteristic allows for highly accurate temperature measurements across a broad range. The temperature coefficient of platinum, typically 3850 ppm/K for industrial PRTs, ensures a significant and measurable change in resistance for even small temperature variations.

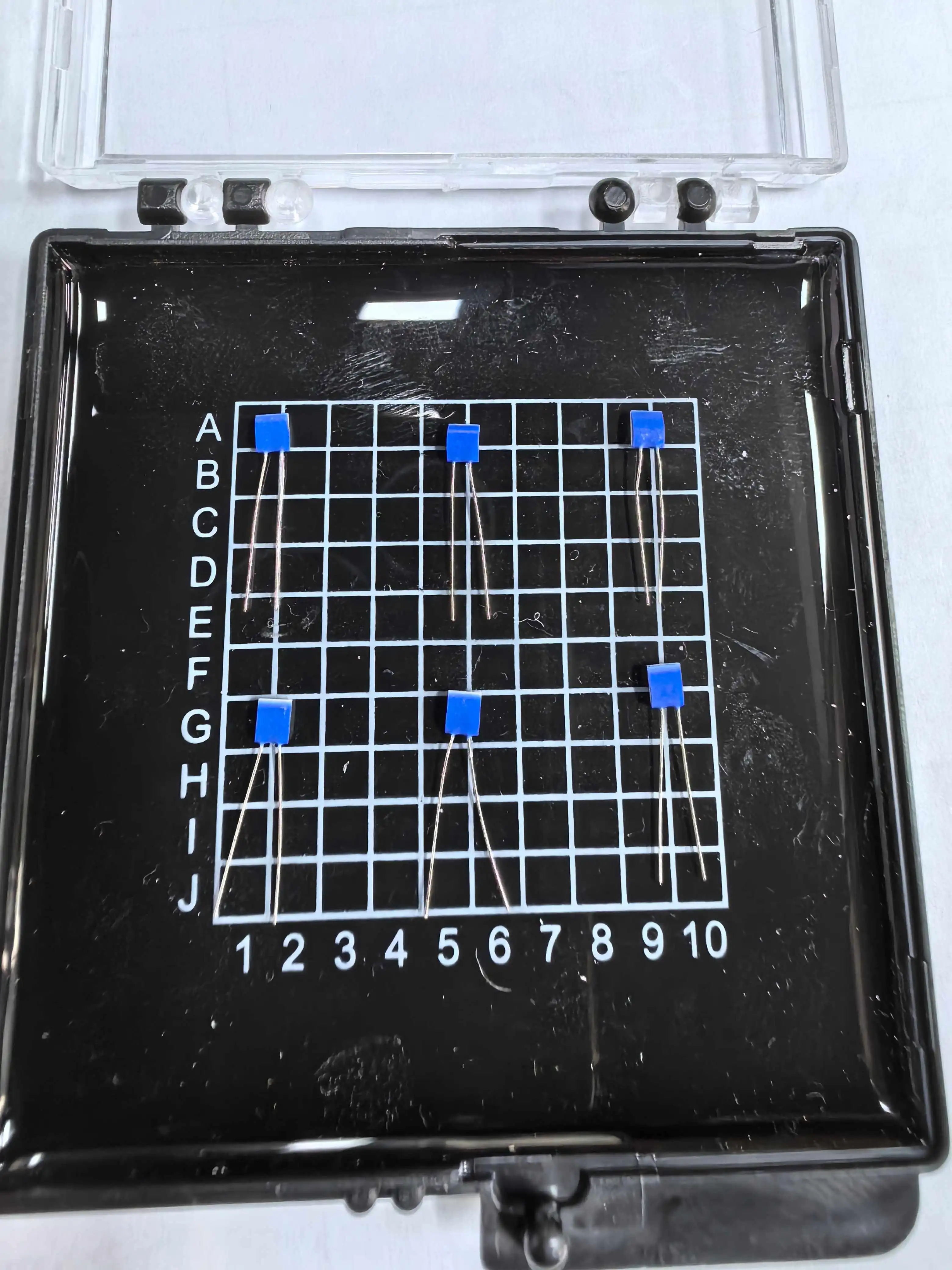

The screw type thermal resistance temperature sensor, a popular variant of PRTs, leverages these properties while offering easy installation and excellent thermal contact. This design allows for precise measurements in various industrial settings, where rugged construction and reliable performance are paramount.

Accuracy and Stability: Hallmarks of Platinum Sensors

One of the most compelling reasons for the widespread adoption of platinum resistance temperature sensors is their remarkable accuracy. High-quality PRTs can achieve accuracies of ±0.01°C or better, surpassing many other temperature sensing technologies. This precision is crucial in industries such as pharmaceuticals, food processing, and semiconductor manufacturing, where even slight temperature deviations can have significant consequences.

Moreover, platinum sensors exhibit exceptional stability over time. Unlike some other sensor types that may drift or degrade, properly constructed PRTs maintain their calibration for extended periods. This long-term stability translates to reduced maintenance costs and improved process reliability, making them a cost-effective choice for industrial applications.

Versatility Across Temperature Ranges

Platinum Resistance Temperature Sensors shine in their ability to operate effectively across an extensive temperature range. Standard industrial PRTs typically cover temperatures from -200°C to +850°C, with specialized designs pushing these limits even further. This versatility is particularly valuable in industries that deal with extreme temperatures, such as cryogenics or high-temperature metallurgy.

The screw type thermal resistance temperature sensor, with its robust construction, can be tailored to specific temperature ranges while maintaining high accuracy. For instance, sensors designed for the range of -50°C to +300°C can achieve tolerances as tight as ±0.15°C, meeting Class A standards according to IEC 60751.

Design Innovations in Screw Type Thermal Resistance Temperature Sensors

Advanced Manufacturing Techniques

The production of high-quality screw type thermal resistance temperature sensors involves sophisticated manufacturing processes. Thin film deposition techniques allow for the creation of precise platinum elements on ceramic substrates, ensuring uniformity and stability. These elements are then carefully encased in protective sheaths, often made of stainless steel or other corrosion-resistant materials, to withstand harsh industrial environments.

Innovative packaging methods, such as hermetic sealing, protect the sensitive platinum element from contamination and moisture, further enhancing the sensor's longevity and reliability. The screw-type design itself represents a clever integration of the sensing element with a practical mounting solution, facilitating easy installation and replacement in industrial equipment.

Customization Options for Diverse Applications

One of the strengths of screw type thermal resistance temperature sensors is their adaptability to various applications. Manufacturers offer a range of customization options to meet specific industry needs. These include:

- Multiple RTD types (Pt100, Pt1000, Pt500) to suit different measurement requirements

- Various wire configurations (two-wire, three-wire, four-wire systems) for optimal signal transmission

- Different lead wire materials (FEP, Silicone Rubber, PTFE, PVC, Metal Braided High-Temperature Wire) to withstand different environmental conditions

- Adjustable insertion lengths and thread sizes to fit diverse mounting scenarios

This flexibility allows engineers to select or design sensors that precisely match their application's needs, whether it's for use in a chemical processing plant, a food production line, or an aerospace testing facility.

Enhanced Performance Through Material Science

Advancements in material science have further improved the performance of screw type thermal resistance temperature sensors. High-purity platinum alloys are now used to create sensing elements with even greater stability and resistance to contamination. Some manufacturers are experimenting with nano-structured platinum films, which promise even faster response times and improved sensitivity.

Moreover, the development of specialized protective coatings has extended the life of these sensors in corrosive or abrasive environments. These innovations have expanded the application range of platinum resistance temperature sensors, making them suitable for use in previously challenging conditions.

Implementing Platinum Resistance Temperature Sensors in Industry

Best Practices for Installation and Maintenance

To maximize the benefits of screw type thermal resistance temperature sensors, proper installation and maintenance are crucial. Key considerations include:

- Ensuring good thermal contact between the sensor and the measured medium

- Proper wiring to minimize lead resistance effects, especially for two-wire configurations

- Regular calibration checks to maintain accuracy over time

- Protection against electrical noise and interference through proper shielding and grounding

By following these best practices, industries can ensure that their platinum resistance temperature sensors provide reliable and accurate measurements for years to come.

Integration with Modern Control Systems

The high accuracy and stability of platinum resistance temperature sensors make them ideal for integration with advanced control systems. Modern industrial automation platforms can take full advantage of the precise measurements provided by these sensors to implement sophisticated control algorithms. This integration enables tighter process control, improved energy efficiency, and enhanced product quality across various industries.

Furthermore, the compatibility of PRTs with industry-standard interfaces and protocols facilitates their incorporation into Industry 4.0 initiatives. The data from these sensors can be easily collected, analyzed, and used for predictive maintenance and process optimization.

Cost-Benefit Analysis in Industrial Applications

While the initial cost of platinum resistance temperature sensors, including screw type thermal resistance temperature sensors, may be higher than some alternatives, their long-term benefits often justify the investment. Factors to consider in a cost-benefit analysis include:

- Reduced downtime due to higher reliability and stability

- Lower maintenance costs from less frequent calibration requirements

- Improved process efficiency and product quality from more accurate temperature control

- Extended sensor lifespan, particularly in harsh environments

For many industrial applications, the superior performance and longevity of platinum resistance temperature sensors translate into significant cost savings over time, making them a prudent choice for critical temperature measurement tasks.

Conclusion

Platinum Resistance Temperature Sensors, particularly the screw type thermal resistance temperature sensor, have rightfully earned their place as the industry's top choice for temperature measurement. Their unmatched accuracy, stability, and versatility make them indispensable in a wide array of applications, from precise laboratory measurements to rugged industrial processes. As technology continues to advance, these sensors are likely to remain at the forefront of temperature sensing solutions, evolving to meet the ever-increasing demands of modern industry.

For those seeking to leverage the benefits of platinum resistance temperature sensors in their applications, partnering with a reputable manufacturer is crucial. Xi'an Tongzida Technology Co., Ltd. offers a comprehensive range of high-quality temperature sensing solutions, including customized options to meet specific industry needs. To explore how our advanced sensor technologies can enhance your temperature measurement capabilities, please contact us at sales11@xatzd.com.