The Technology Behind High Precision Threaded Thermistor Sensors

High precision threaded thermistor temperature sensors are marvels of modern engineering, combining sophisticated materials science with precision manufacturing techniques. At their core, these sensors utilize temperature-sensitive resistive elements, typically made from platinum, which exhibit a highly predictable change in resistance as temperature fluctuates. This resistance change is then measured and converted into accurate temperature readings.

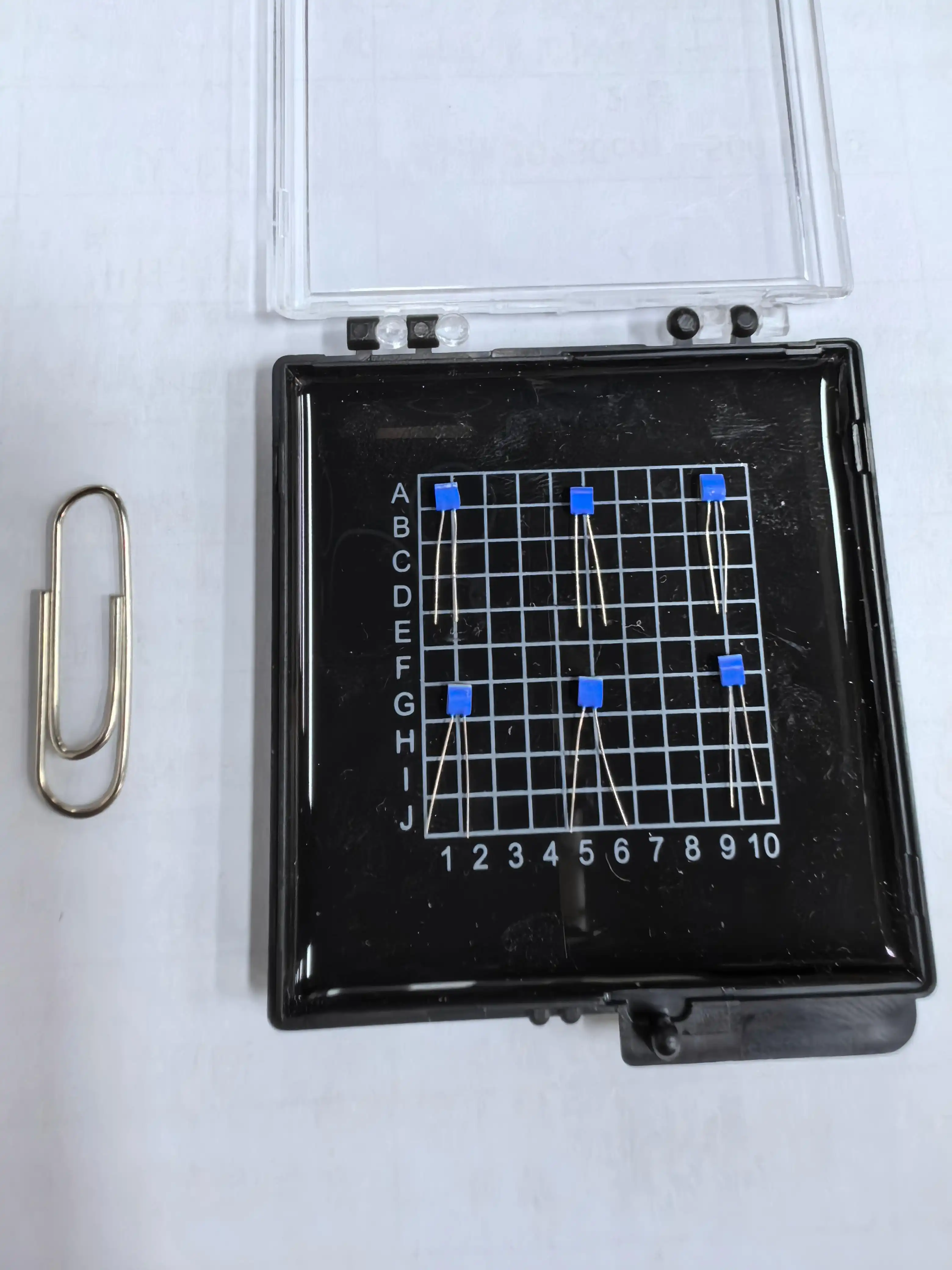

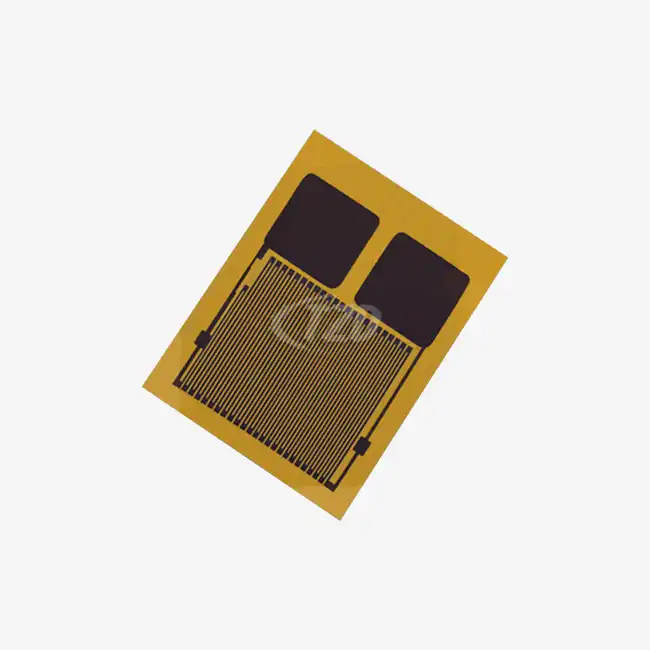

The thin-film platinum resistor technology employed in these sensors is a key factor in their exceptional performance. By depositing a thin layer of platinum on a ceramic substrate, manufacturers can create sensors with extremely fast response times and high accuracy. The thin-film construction allows for rapid heat transfer between the sensor element and the measured environment, resulting in near-instantaneous temperature readings.

The threaded design of high precision threaded thermistor temperature sensors serves multiple purposes. It offers a secure and standardized method of installation, ensuring stable positioning and consistent thermal contact with the measured medium for accurate readings. Additionally, the threads can be customized to match different process connections, enhancing compatibility with diverse equipment setups. This adaptability makes high precision threaded thermistor temperature sensors ideal for use in a wide range of industrial, laboratory, and scientific applications where reliability and accuracy are essential.

Precision Engineering for Optimal Performance

The fabricating prepare for tall accuracy strung thermistor sensors includes fastidious consideration to detail. Each sensor experiences thorough quality control measures to guarantee compliance with rigid benchmarks such as IEC60751. The temperature coefficient of these sensors, ordinarily 3850 ppm/K, is carefully calibrated to give steady and dependable estimations over a wide temperature extend, regularly traversing from -200°C to +850°C.

Advanced packaging techniques are employed to protect the sensitive sensor elements from environmental factors such as moisture, vibration, and electromagnetic interference. This vigorous development contributes to the sensors' capacity to keep up long-term soundness, with float rates as moo as 0.04% over expanded periods of utilize.

Unparalleled Accuracy and Speed in Temperature Sensing

The hallmark of high precision threaded thermistor temperature sensors is their exceptional accuracy and rapid response times. These sensors can achieve remarkable precision, with some models offering tolerances as tight as ±0.01°C within specific temperature ranges. This level of precision is pivotal in applications where indeed minor temperature varieties can have critical results, such as in pharmaceutical fabricating or semiconductor processing.

Reaction times for these sensors can be as quick as 0.05 seconds, allowing for real-time checking of rapidly changing warm conditions. This speed is especially important in energetic situations where temperature changes happen quickly, such as in chemical responses or motor testing offices.

Customization for Specific Applications

One of the strengths of high precision threaded thermistor sensors is their adaptability to various applications. Manufacturers offer a range of options for nominal resistance values, including Pt100, Pt500, and Pt1000, allowing users to select the most appropriate sensor for their specific measurement needs and instrumentation requirements.

Wire arrangements are another region of customization, with two-wire, three-wire, and four-wire frameworks accessible. Four-wire setups are especially valuable for high-precision estimations, as they successfully dispense with lead wire resistance mistakes.

Lead wire materials can be selected based on the operating environment, with options including FEP (Fluorinated Ethylene Propylene), Silicone Rubber, PTFE (Polytetrafluoroethylene), PVC (Polyvinyl Chloride), and Metal Braided High-Temperature Wire. This variety ensures that the sensors can withstand harsh conditions while maintaining their accuracy and reliability.

Applications and Industry Impact of High Precision Threaded Thermistor Sensors

The flexibility and performance of high precision threaded thermistor temperature sensors have led to their widespread adoption across a broad range of industries and applications. In the industrial sector, these sensors play a crucial role in process control and quality assurance. Their ability to deliver accurate, real-time temperature data allows manufacturers to optimize production processes, reduce waste, and improve product consistency, all while ensuring operational efficiency and compliance with stringent quality standards.

In the medical field, these sensors are invaluable for precise temperature monitoring in critical care situations, laboratory equipment, and diagnostic devices. Their fast response times and high accuracy contribute to improved patient care and more reliable research outcomes.

The automotive industry relies on these sensors for engine management systems, emissions control, and battery temperature monitoring in electric vehicles. The sensors' ability to withstand vibration and extreme temperatures makes them ideal for these demanding applications.

Advancing Scientific Research and Aerospace Technology

Scientific research benefits greatly from the precision and stability of these sensors. In cryogenics, material science, and particle physics experiments, accurate temperature measurement is often crucial to the validity of results. High precision threaded thermistor sensors provide researchers with the tools they need to push the boundaries of scientific understanding.

In the aerospace industry, these sensors are used in everything from environmental control systems to engine monitoring. Their reliability under extreme conditions and ability to withstand high g-forces make them essential components in aircraft and spacecraft design.

The effect of tall exactness strung thermistor temperature sensors expands past these businesses, finding applications in renewable vitality frameworks, nourishment preparing, and natural observing. As development continues to improvement, the ask for in fact more correct and responsive temperature estimation is likely to create, driving energize progression in sensor arrange and manufacturing.

Conclusion

High precision threaded thermistor temperature sensors represent the cutting edge of temperature measurement technology. Their combination of accuracy, speed, and durability makes them indispensable tools across a wide range of industries and applications. As we continue to push the boundaries of what's possible in fields like industrial automation, medical diagnostics, and scientific research, these sensors will play an increasingly vital role in enabling new discoveries and improving existing processes.

For those seeking to harness the power of these advanced sensors in their own projects or applications, it's crucial to work with experienced manufacturers who can provide customized solutions tailored to specific needs. By leveraging the latest in thin-film technology and precision engineering, high precision threaded thermistor sensors are set to remain at the forefront of temperature measurement for years to come.

To learn more about how these innovative sensors can benefit your specific application, or to discuss custom sensor solutions, please contact our team of experts at sales11@xatzd.com. Our commitment to quality and innovation ensures that you'll receive the highest caliber of temperature sensing technology available in the market today.