- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Medical equipment temperature measurement is the first choice! The high-precision advantage of Pt100 SMD thin film platinum resistance

Medical equipment has extremely strict requirements for temperature measurement accuracy, stability, and reliability, and even a slight error can affect diagnostic results or treatment effectiveness. The Pt100 SMD thin film platinum resistor, with its high precision and low drift characteristics that comply with DIN EN 60751 standard, has become an ideal choice for temperature measurement in medical equipment. This article analyzes its application value and selection points in the medical field.

H2: The core advantages of PT100-SMD in adapting medical equipment

H3: Ultra high precision, meeting the strict standards of the medical industry

Medical equipment, such as in vitro diagnostic devices, medical refrigerators, and blood analyzers, typically require temperature measurement accuracy within ± 0.1 ℃. The A-grade tolerance of Pt100 SMD is ± (0.15+0.002 | t |), and the measurement error within the commonly used temperature range (0~+50 ℃) is ≤± 0.2 ℃, fully meeting the medical industry standards. The resistance temperature relationship follows a precise calculation formula, which can accurately feedback temperature changes and provide data support for the normal operation of medical equipment.

H3: Low drift characteristics, long-term stability and reliability

Medical equipment usually requires long-term continuous operation, which places extremely high demands on the long-term stability of sensors. After continuous operation at 200 ℃ for 1000 hours, the resistance drift of R (0 ℃) of Pt100 SMD is ≤ 0.06%. It does not require frequent calibration during long-term use to avoid the decrease in equipment accuracy caused by sensor drift, ensure the reliability of medical data, and reduce the maintenance workload of medical staff.

H3: Clean and safe, suitable for medical environments

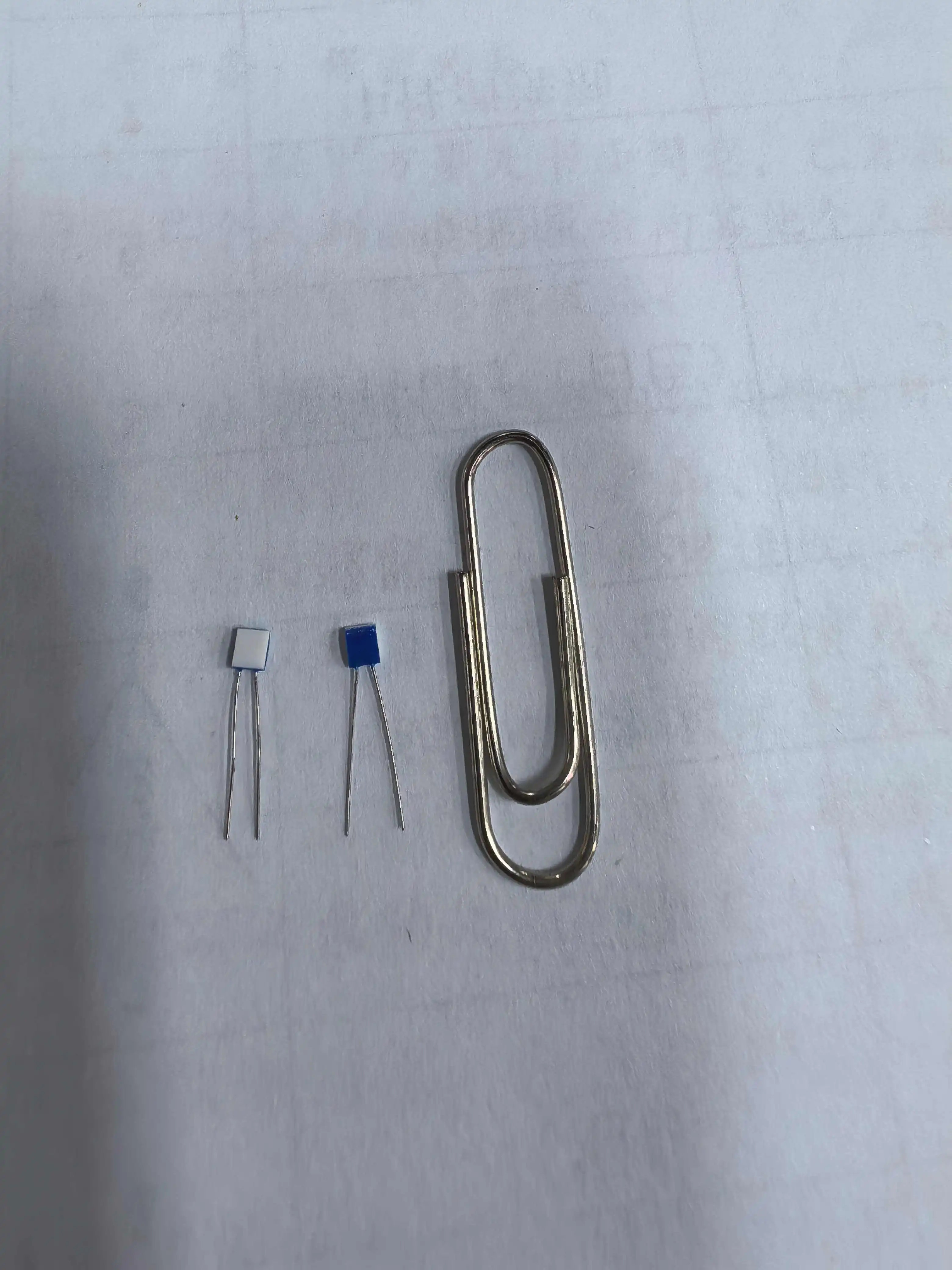

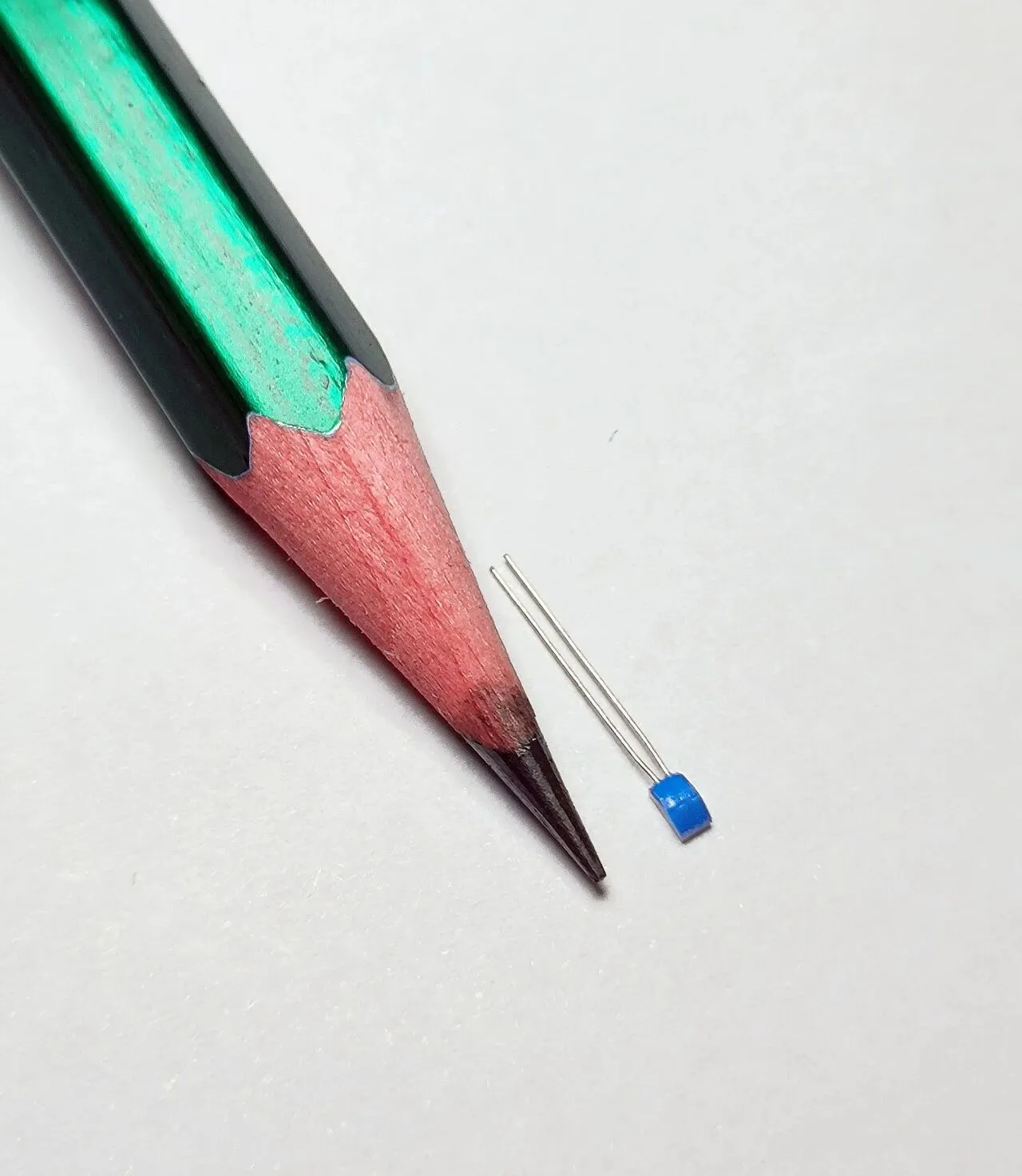

The components of medical equipment need to meet the requirements of cleanliness and pollution-free. Pt100 SMD adopts vacuum plastic packaging, which can effectively prevent moisture, oxidation, and pollution, and avoid being affected by impurities during transportation and storage. Its tin alloy terminals and SMD packaging design release no harmful substances, meet the environmental requirements of medical equipment, and will not cause harm to the medical environment and human body.

H2: The specific application of Pt100-SMD in medical equipment

H3: In vitro diagnostic equipment

In vitro diagnostic equipment (such as biochemical analyzers and immune analyzers) require precise control of reaction temperature to ensure the accuracy of test results. The A-grade model of Pt100 SMD (Pt100. SMD. M150.1206. A) is installed near the reaction tank to monitor temperature in real-time. Its high-precision characteristics ensure that the reaction temperature is controlled within the set value ± 0.1 ℃, avoiding temperature deviation and distortion of detection results, providing reliable basis for disease diagnosis.

H3: Medical refrigerators and freezers

Medical refrigerators are used to store drugs, vaccines, blood and other materials, and the temperature should be strictly controlled within 2-8 ℃; The freezer is used to store samples, organs, etc., and the temperature may be as low as -50 ℃. The temperature measurement range of Pt100 SMD M200 type (B or 2B grade) covers -50~+200 ℃, which can accurately monitor the internal temperature of refrigerators and freezers. When the temperature exceeds the threshold, an alarm mechanism is triggered to ensure the quality of materials and avoid medical accidents caused by abnormal temperature.

H3: Hemodialysis equipment

Hemodialysis equipment needs to control the temperature of the dialysate during the treatment process to ensure consistency with human body temperature (around 37 ℃). Excessive or insufficient temperature can affect the treatment effect and even cause harm to the patient. Pt100 SMD is integrated into the dialysate tubing to monitor temperature in real-time. Its high linearity and low drift characteristics ensure precise temperature control, providing patients with a safe and comfortable treatment experience.

H2: Key points for Pt100 SMD selection in medical equipment scenarios

H3: Prioritize selecting high-level accuracy

Medical equipment has strict requirements for accuracy, and A-grade models (Pt100. SMD. M150.1206. A) are preferred. Their Ro (0 ℃) resistance tolerance is 100 ± 0.06 Ω, with the highest accuracy, which can meet the needs of core medical equipment such as in vitro diagnostic equipment and hemodialysis equipment; If the temperature measurement range includes negative temperatures (such as medical freezers), choose the B-grade model (Pt100. SMD. M200.1206. B) with an accuracy of ± (0.3+0.005 | t |), which can still maintain high accuracy in negative temperature scenarios.

H3: Pay attention to matching temperature range with equipment requirements

Room temperature medical equipment (such as in vitro diagnostic equipment, hemodialysis equipment): choose M150 type (0~+150 ℃), adapt to the working temperature range of the equipment;

Low temperature medical equipment (such as medical freezers and low-temperature sample storage devices): Choose the M200 type (-50~+200 ℃) to cover the low-temperature storage temperature and ensure accurate temperature measurement.

H3: Consider welding and integration compatibility

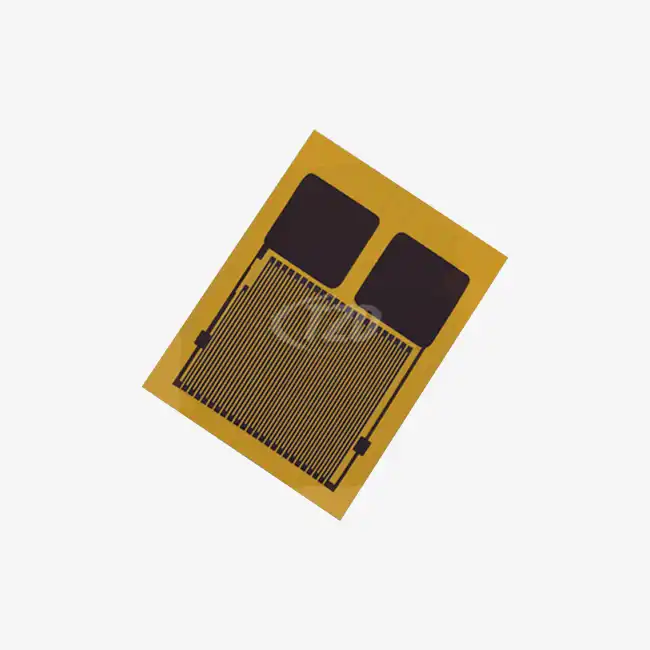

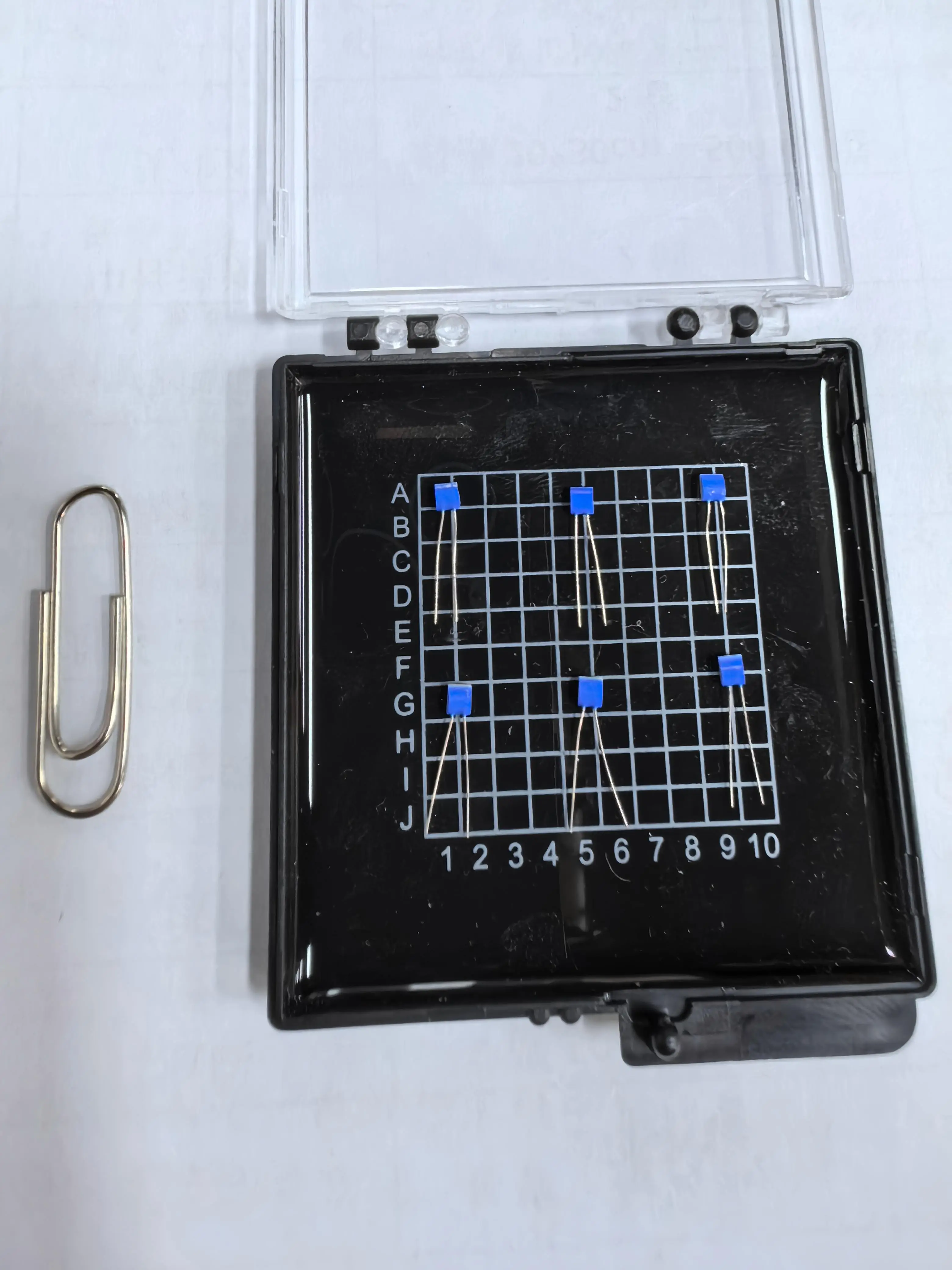

The PCB board design of medical equipment is usually more precise. The size of Pt100 SMD is 3.2 × 1.6 × 0.7mm, and the SMD packaging design can be easily integrated into precision PCB boards. It supports automated soldering processes such as reflow soldering and wave soldering, and recommends using high-temperature solder paste for soldering at 230-240 ℃ to meet the mass production needs of medical equipment, ensuring firm soldering and stable performance.

H2: Precautions for using Pt100 SMD in medical equipment

H3: Installation and Protection

The installation location should be far away from strong electromagnetic interference sources to avoid affecting the signal transmission of sensors and ensure accurate temperature measurement data;

If the sensor is installed in a position that comes into direct contact with the human body or medical supplies, a protective shell should be added to avoid direct contact between the sensor and ensure cleanliness and safety;

During installation, avoid squeezing or colliding with sensors to prevent structural damage from affecting performance.

H3: Calibration and Maintenance

Before medical equipment leaves the factory, Pt100 SMD needs to undergo secondary calibration to ensure compliance with the equipment's accuracy requirements;

For long-term medical equipment, it is recommended to calibrate the sensor once a year to ensure long-term stability and avoid accuracy degradation caused by drift;

During storage and transportation, keep the vacuum packaging intact, avoid moisture and oxidation, and ensure the initial performance of the sensor.

FAQ

Q1: Can the A-grade accuracy of PT100-SMD meet the requirements of in vitro diagnostic equipment?

A: Okay. The tolerance of Class A is ± (0.15+0.002 | t |), and within the commonly used range of 0~+50 ℃ for in vitro diagnostic equipment, the measurement error is ≤± 0.2 ℃, fully meeting the accuracy requirements of the medical industry for this type of equipment.

Q2: Does the PT100-SMD meet the environmental standards for medical devices?

A: Compliant. The materials and packaging design used have no harmful substance release, comply with environmental standards such as RoHS, and can be safely used for medical equipment.

Xi'an Tongzida Technology Co., Ltd. is a leading manufacturer and supplier of advanced thermistor technology, focusing on providing high-performance temperature sensors for demanding industrial applications. We have deep expertise in microsensor manufacturing, specific packaging technologies, and multi-sensor integration methods, which can ensure the excellent performance and reliability of our thermistors. As a trusted supplier of precision temperature measurement solutions, we offer a complete thermistor system, including sensor chips, testing systems, and analysis software. Please feel free to contact our technical experts at any time. ventes11@xatzd.com Discuss your specific requirements for thermistors and learn how our advanced thermal resistor optimization and manufacturing capabilities can enhance the performance and reliability of your temperature measurement system.

Learn about our latest products and discounts through SMS or email