- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Pt100 SMD vs NTC sensors: Who is the king of cost-effectiveness in the field of temperature measurement?

In the temperature sensor market, Pt100 SMD thin film platinum resistors and NTC sensors are two popular products that are suitable for different scenarios. This article provides a comprehensive comparison from multiple dimensions such as performance, cost, and application to help you determine who is the most cost-effective choice for you.

H2: Core performance comparison, precision and stability big competition

H3: Linearity Comparison

Pt100 SMD: Following DIN EN 60751 standard, the output linearity is extremely high, and the resistance temperature relationship conforms to precise calculation formulas (t ≥ 0 ℃ and t<0 ℃ correspond to different formulas). The measurement error is small throughout the entire temperature range, and temperature changes can be accurately fed back without complex calibration.

NTC sensor: The output curve is non-linear and has significant errors over a wide temperature range. It needs to be compensated through software calibration, otherwise it will affect the temperature measurement accuracy, especially at the high and low temperature ends, where non-linear problems are more prominent.

H3: Stability comparison

Pt100 SMD: Excellent long-term stability. After continuous operation at 200 ℃ for 1000 hours, the resistance drift of R (0 ℃) is ≤ 0.06%. It does not require frequent calibration during long-term use and has low maintenance costs.

NTC sensor: Drift is significant during long-term use, and is greatly affected by environmental humidity, temperature cycling, and other factors. After 1-2 years of use, the accuracy decreases significantly, requiring regular calibration or replacement, and high maintenance costs.

H3: Comparison of temperature range coverage

Pt100 SMD: The temperature measurement range covers -50 ℃~+200 ℃, and some models support 0~+150 ℃. It has a wide temperature range and is suitable for various complex scenarios, from low-temperature storage to high-temperature production, and can work stably.

NTC sensor: The temperature measurement range of conventional NTC sensors is mostly -40 ℃~+125 ℃, with poor high temperature tolerance and inability to adapt to high temperature scenarios of 200 ℃, limiting their application range.

H2: Comparison of cost and process compatibility to meet production needs

H3: Comparison of Procurement Costs

Pt100 SMD: The single cost is higher than conventional NTC sensors, but its accuracy and stability are better, and the comprehensive cost (including maintenance cost) for long-term use is lower.

NTC sensor: Low cost per unit, suitable for scenarios with low precision and stability requirements, bulk procurement, and short-term use, with high overall cost for long-term use.

H3: Comparison of Welding Process Compatibility

Pt100 SMD: Supports various automated soldering processes such as reflow soldering and wave soldering. It is recommended to use high-temperature solder paste for soldering at 230-240 ℃, which can seamlessly integrate into SMT production lines with high soldering yield and is suitable for mass production.

NTC sensors: Some NTC sensors only support manual welding, which results in poor compatibility with automated welding and low efficiency in mass production. Additionally, manual welding can easily cause sensor damage, affecting production yield.

H3: Installation and Integration Comparison

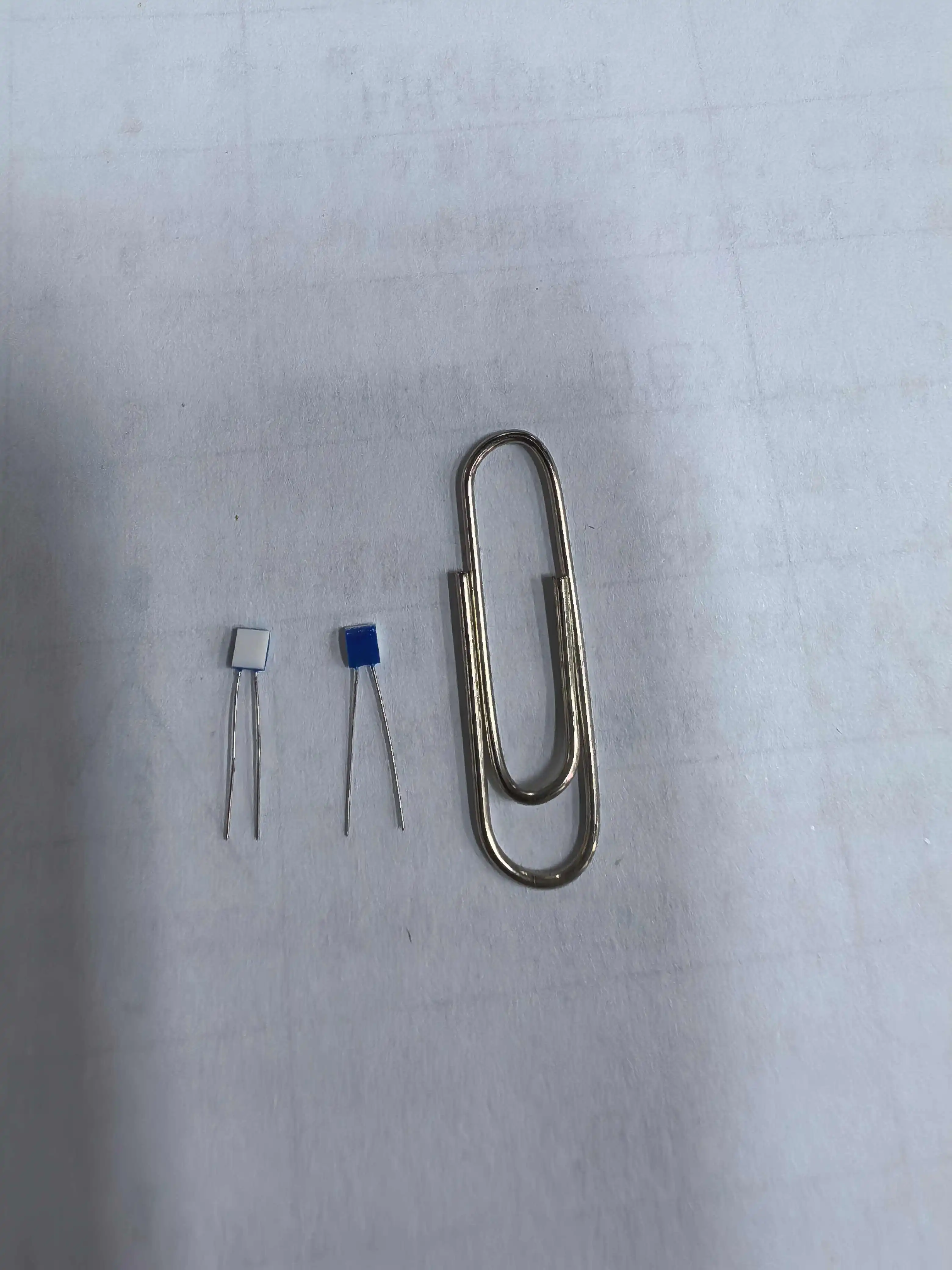

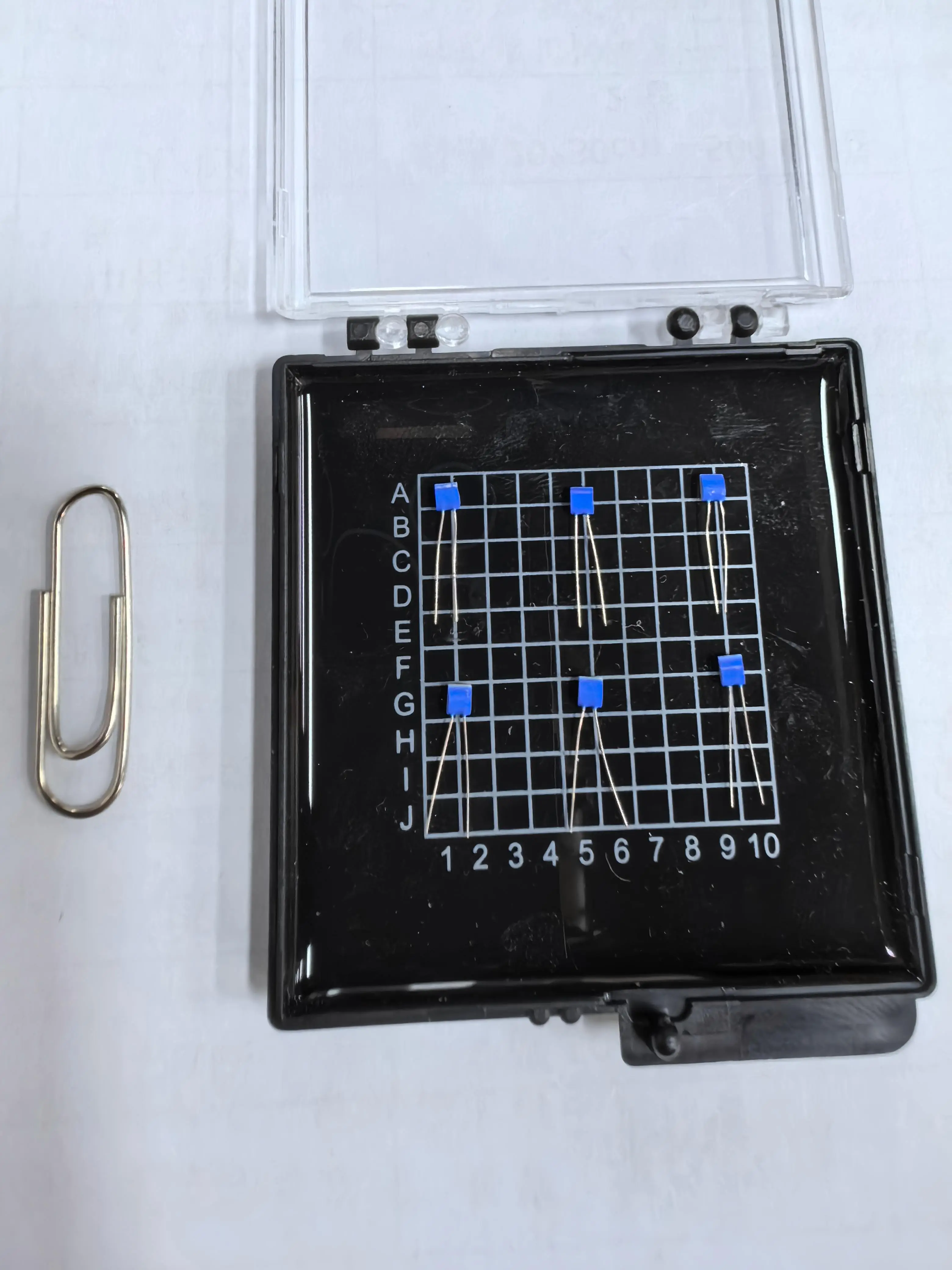

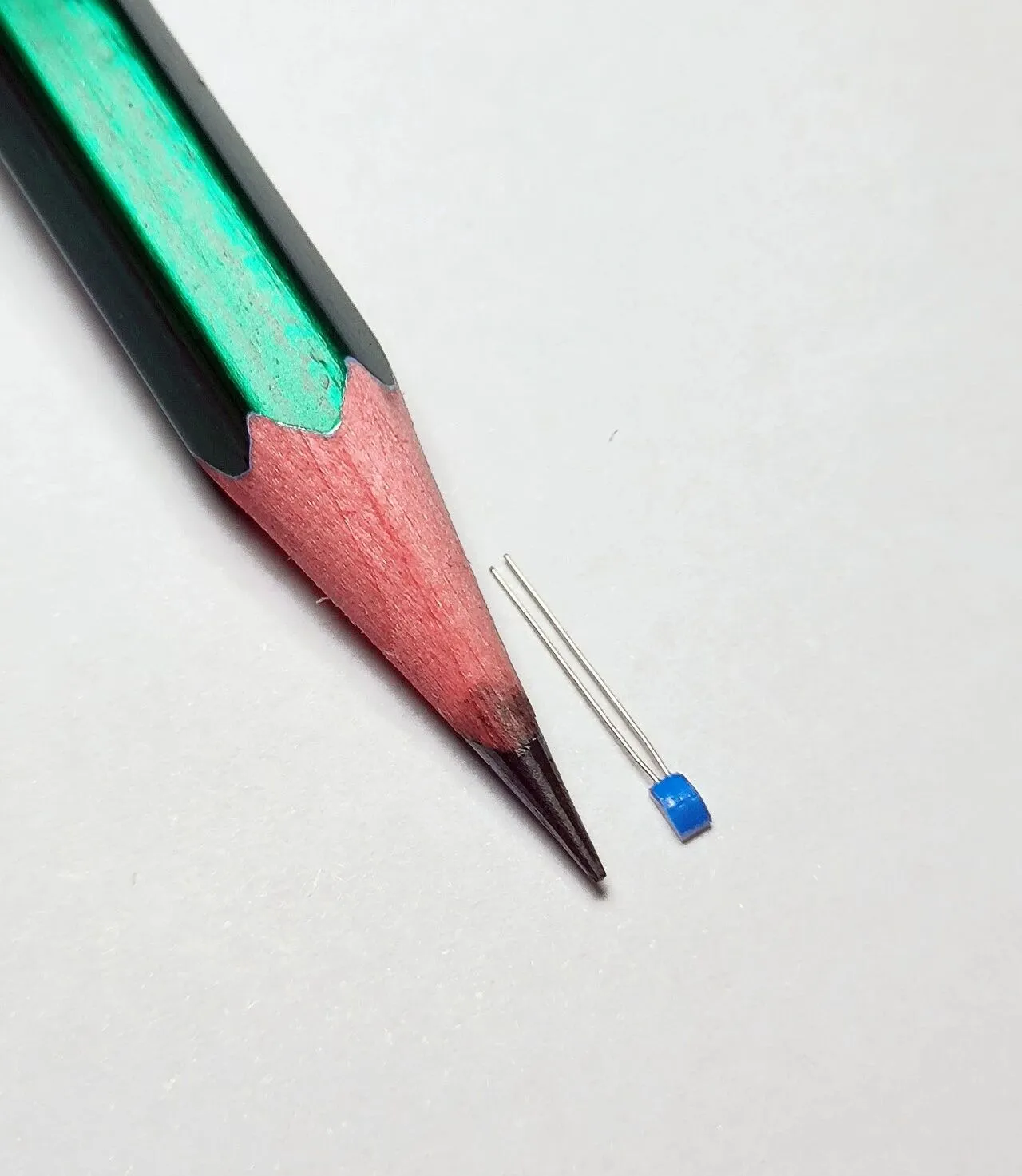

Pt100 SMD: with a size of 3.2 × 1.6 × 0.7mm, the SMD package design facilitates integration into PCB boards without taking up too much space, adapting to the trend of miniaturization of electronic devices.

NTC sensors: Some NTC sensors are packaged with lead wires, which are large in size and require additional fixing structures during installation. They have low integration and are not suitable for miniaturized devices.

H2: Comparing application scenarios, who is more suitable for your needs?

H3: Advantage scenarios of Pt100-SMD

High precision demand scenarios: laboratory equipment, medical equipment, precision industrial control, etc., with strict requirements for temperature measurement accuracy and stability. The linearity and low drift characteristics of Pt100 SMD can meet the needs;

Wide temperature range scenarios: outdoor equipment, industrial high and low temperature production, cold chain logistics, etc. The temperature range coverage of -50 ℃~+200 ℃ can adapt to complex environments;

Automated production scenarios: Electronic equipment manufacturers, large industrial enterprises, etc. Mass production requires automated welding processes, and Pt100 SMD has stronger process compatibility.

H3: Advantageous Scenarios of NTC Sensors

Low cost batch scenarios: ordinary small household appliances, entry-level electronic devices, etc., with low precision requirements and the need to control procurement costs. The low price advantage of NTC sensors is obvious;

Short term usage scenarios: temporary environmental monitoring, disposable devices, etc., no need for long-term stable operation, NTC sensors can meet basic temperature measurement needs;

Room temperature scenario: indoor electronic devices, ordinary environmental monitoring, etc., with a stable temperature range of -40 ℃~+125 ℃, the performance of NTC sensors is sufficient for use.

H2: Comprehensive evaluation of cost-effectiveness, who is the ultimate winner?

H3: Short term low-cost demand: NTC sensors have more advantages

If your application scenario does not require high accuracy and stability, and has limited budget, large batch size, and short-term use, the low price advantage of NTC sensors can meet basic needs and is a short-term cost-effective choice.

H3: Long term high demand: Pt100 SMD offers higher cost-effectiveness

If your application scenario requires precision, stability, temperature range coverage, or process compatibility, and requires long-term use, Pt100 SMD, although initially expensive to purchase, has good long-term stability, low maintenance costs, a wide range of applications, and a higher overall cost-effectiveness, which can provide guarantees for product quality and production efficiency.

FAQ

Q1: How much higher is the cost of PT100-SMD compared to NTC?

A: The cost of a single Pt100 SMD is about 2-3 times that of a conventional NTC sensor, but it does not require frequent calibration and replacement during long-term use, resulting in a lower overall cost.

Q2: Can the nonlinear problem of NTC sensors be completely solved through calibration?

A: Nonlinear compensation can be achieved through software, but it will increase research and development costs and complexity, and still cannot reach the linearity level of Pt100 SMD over a wide temperature range.

Q3: Can PT100-SMD replace all NTC sensor application scenarios?

A: I can't. In batch scenarios with extremely low precision requirements and cost sensitivity, NTC sensors still have irreplaceable advantages, and Pt100 SMD is more suitable for mid to high end and high demand scenarios.

Q4: What is the welding yield of Pt100 SMD on an automated production line?

A: As long as the welding process requirements are strictly followed, the welding yield of Pt100 SMD can reach over 99%, far higher than that of manually welded NTC sensors.

Q5: How should I choose if my scenario requires both accuracy and cost control?

A: You can choose the 2B grade of Pt100 SMD, which has lower cost than A and B grades and higher accuracy than conventional NTC sensors. It can find a balance between accuracy and cost, making it a cost-effective choice.

References

Xi'an Tongzida Technology Co., Ltd Pt100 SMD Technical Specification (Version V2.0)

NTC Thermistor Technical Manual GB/T 23644-2009.

If your application scenario requires accuracy, stability, and temperature range, and pursues long-term comprehensive cost-effectiveness, Pt100 SMD thin film platinum resistors are undoubtedly a better choice; If only short-term low-cost temperature measurement is needed, NTC sensors can be used as an alternative. If you need to further understand the detailed parameters, selection suggestions or obtain sample testing of Pt100 SMD, you can contact Xi'an Tongzida Technology Co., Ltd.Email:sales11@xatzd.com and let our professional team provide you with customized solutions!

Author information

Author: Sun Yue, an analyst in the electronic components industry. Introduction: Focusing on temperature sensor market analysis and comparison, with 8 years of industry research experience, proficient in evaluating the cost-effectiveness of components from multiple dimensions such as performance, cost, and application, providing objective and professional selection suggestions for enterprises.

Learn about our latest products and discounts through SMS or email