- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What Makes Platinum Resistance Thermistors Ideal for Industrial Automation?

1. What Makes Platinum Resistance Thermistors Ideal for Industrial Automation? Stable Performance Explained

In the complex ecosystem of industrial automation, temperature monitoring is a cornerstone of operational efficiency and product quality. Among various temperature-sensing components, platinum resistance thermistors stand out for their unmatched reliability—but why are they the preferred choice for industrial automation applications? This article breaks down the core advantages of platinum resistance thermistors and how their specs align with the demands of modern automation systems.

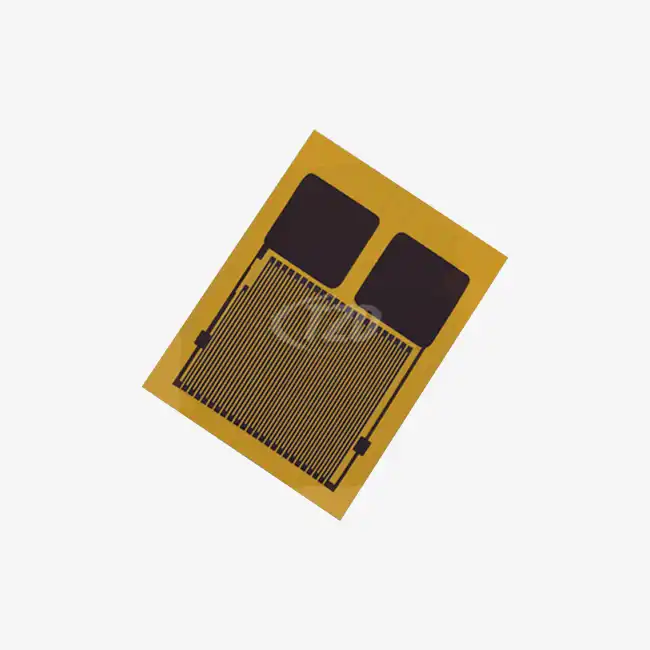

Key Specifications of Platinum Resistance Thermistors for Industrial Automation

Industrial automation environments are often harsh, with extreme temperatures, vibrations, and constant operational demands. Platinum resistance thermistors are engineered to thrive in these conditions, thanks to their tailored specifications. The standard 3850 ppm/°C temperature coefficient (TCR) ensures consistent and accurate temperature readings across a wide range, which is critical for processes like assembly line heating, equipment cooling systems, and material processing.

Another vital spec is the long-term stability: ≤±0.04% resistance drift of R₀ (0°C reference) after 1000 hours at 500°C. This means platinum resistance thermistors maintain precision even during prolonged use, reducing the need for frequent calibrations or replacements— a key cost-saving factor for automation facilities. Additionally, their vibration resistance (≥40g acceleration, 10–2000 Hz) and shock resistance (≥100g acceleration, 8 ms half-sine wave) make them durable enough to withstand the mechanical stress of automated production lines.

Why Platinum Resistance Thermistors Outperform Other Sensors in Automation

When compared to thermocouples or thermistors made from other materials, platinum resistance thermistors offer distinct benefits for industrial automation. Thermocouples, for example, may have wider temperature ranges but lack the precision of platinum RTDs, especially in the moderate temperature zones (common in most automation processes). Other thermistors, such as NTC or PTC, can be cost-effective but suffer from poor long-term stability, which is a dealbreaker for continuous automation operations.

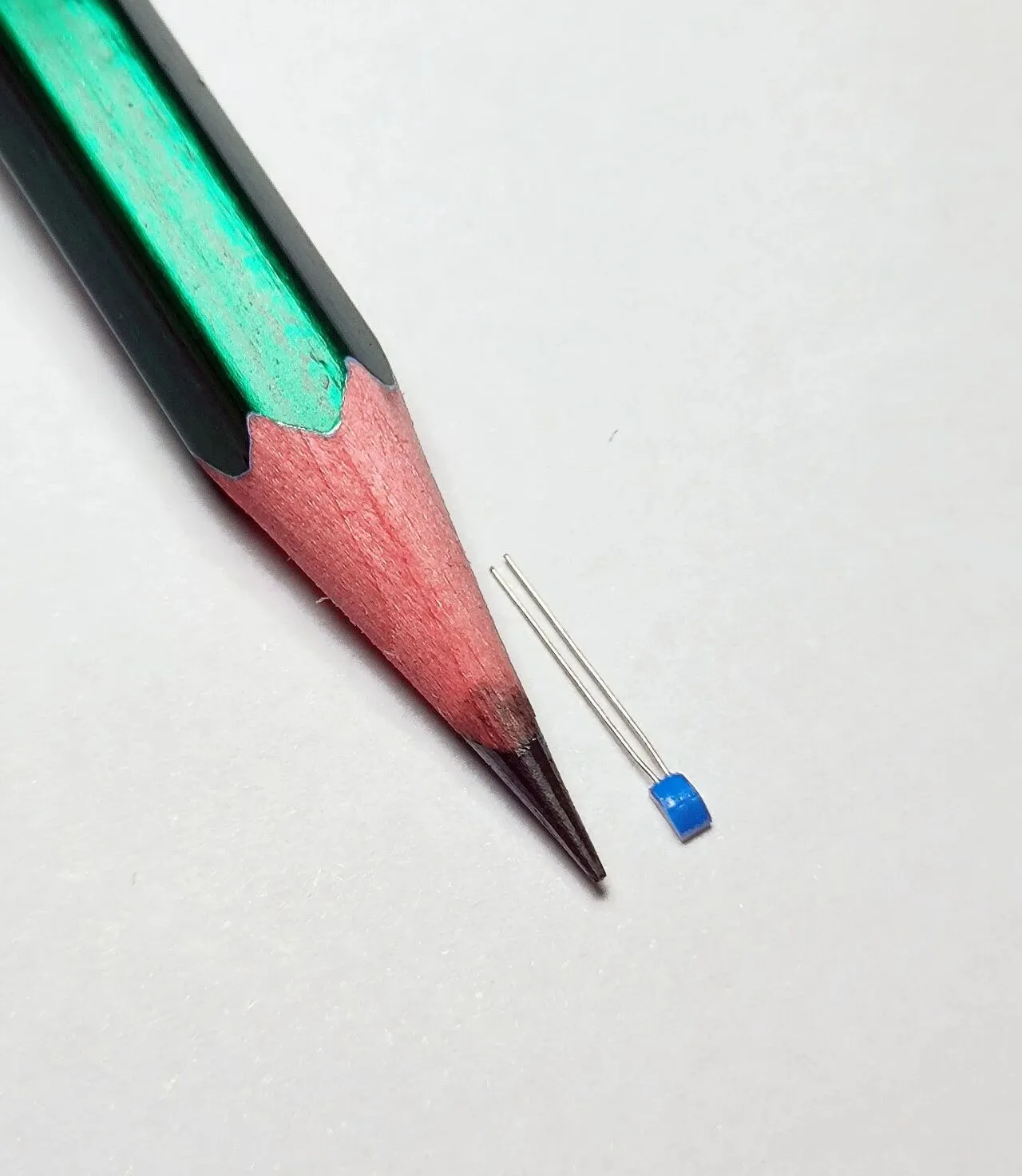

The self-heating coefficient of 0.4°C/mW (at 0°C) is another advantage. In industrial automation, sensors are often placed in confined spaces or near heat-sensitive components. platinum resistance thermistors generate minimal self-heat, ensuring their readings aren’t skewed by their own operation—critical for maintaining process accuracy. Their fast response time (t₀.₉=0.15s in water flow, t₀.₉=10s in airflow) also allows for real-time temperature feedback, enabling automation systems to adjust processes promptly.

Practical Applications of Platinum Resistance Thermistors in Industrial Automation

1. Assembly Line Temperature Monitoring

Automated assembly lines, such as those in automotive or electronics manufacturing, rely on precise temperature control to ensure component integrity. Platinum resistance thermistors are used to monitor the temperature of bonding agents, solder, and heat-treated parts. Their accuracy ensures consistent bonding strength and part quality, reducing defective products.

2. HVAC Systems in Automation Facilities

Industrial HVAC systems maintain optimal working conditions for both equipment and personnel. platinum resistance thermistors are integrated into these systems to monitor air and fluid temperatures, ensuring efficient heating and cooling. Their durability and stability make them ideal for 24/7 operation in large facilities.

3. Robotics Temperature Regulation

Automated robots generate heat during operation, which can affect their performance and lifespan. Platinum resistance thermistors are placed in robot joints and control units to monitor temperature, triggering cooling systems when needed. This proactive regulation extends the life of robotic components and minimizes downtime.

FAQ: Platinum Resistance Thermistors for Industrial Automation

Q: Can platinum resistance thermistors withstand high temperatures in industrial automation? A: Yes—they operate reliably up to 500°C, with insulation resistance >2 MΩ at that temperature, making them suitable for high-heat processes like metal fabrication or plastic molding.

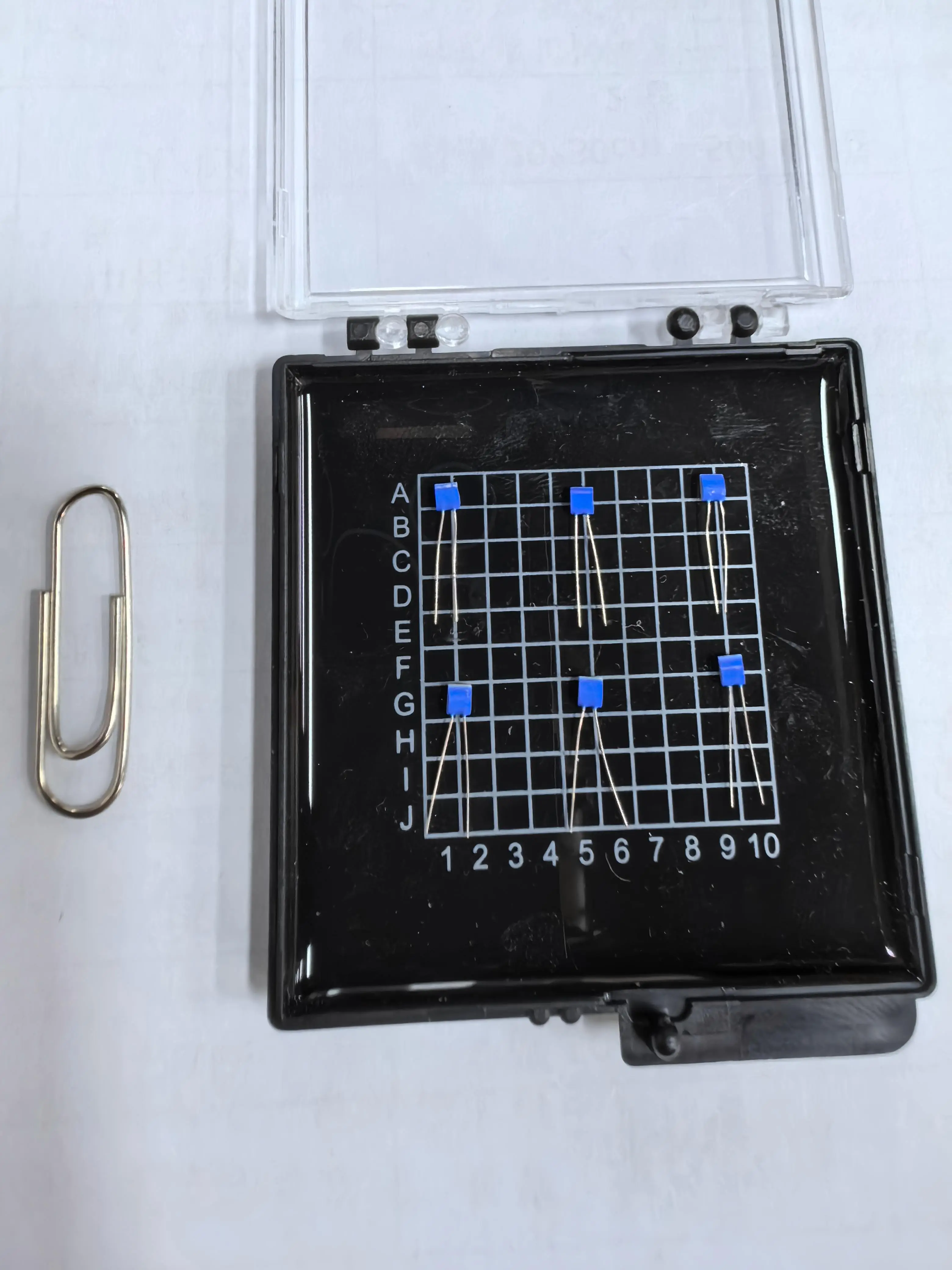

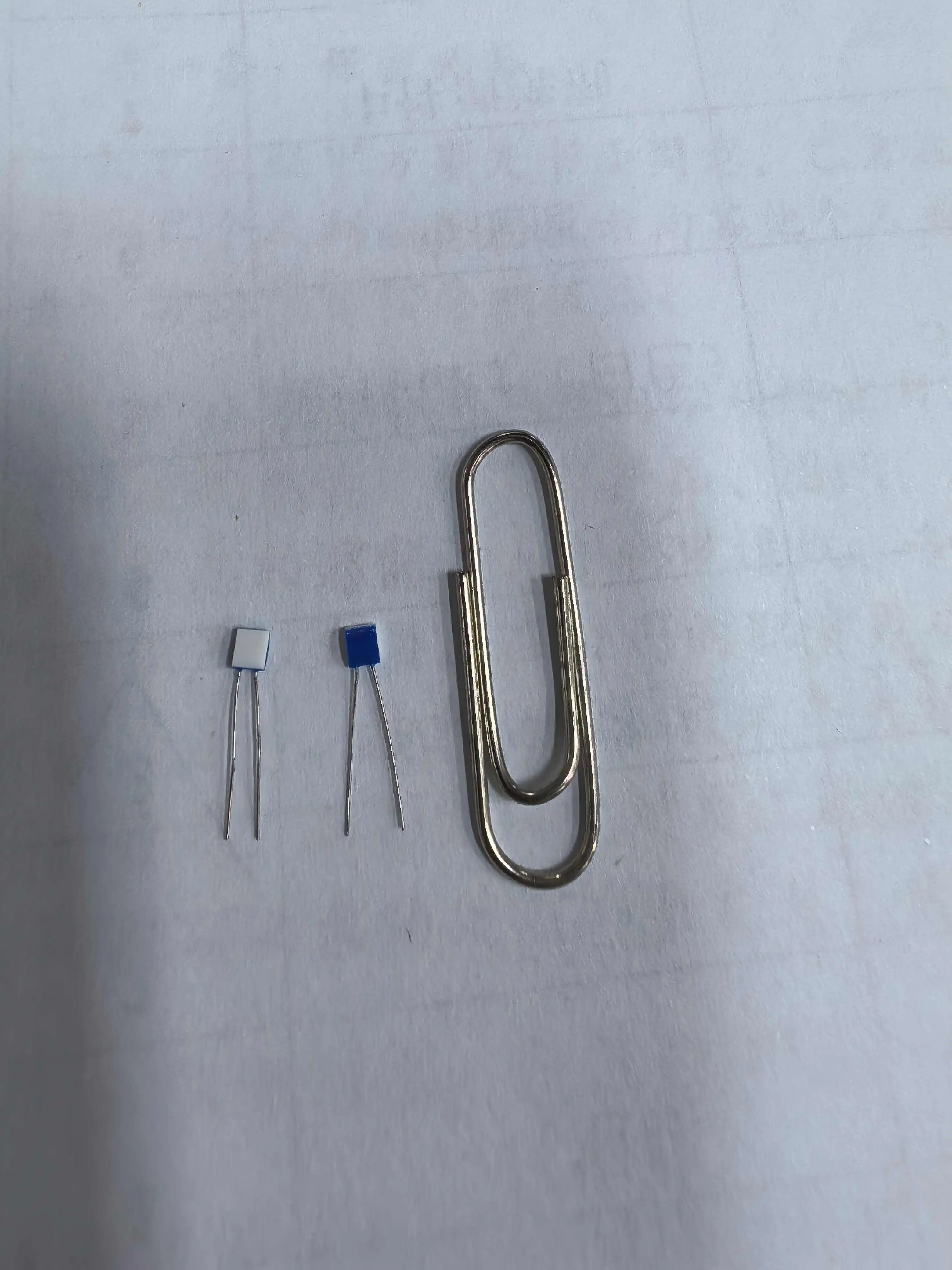

Q: Are platinum resistance thermistors compatible with standard automation control systems? A: Absolutely. They have standard lead specifications (10mm length, 0.2mm diameter) and flexible lead materials, making them easy to integrate with PLCs and other automation controllers.

Q: What is the lifespan of platinum resistance thermistors in automation applications? A: With their long-term stability and durable construction, they typically last 5–10 years in continuous industrial use, depending on the environment.

Conclusion & CTA

For industrial automation systems that demand precision, durability, and long-term reliability, platinum resistance thermistors are the optimal temperature-sensing solution. Their tailored specifications—from TCR stability to vibration resistance—align perfectly with the harsh conditions and continuous operation of modern automation facilities.

If you’re upgrading your industrial automation system or looking for a reliable temperature sensor, contact our team today. We offer custom platinum resistance thermistor solutions tailored to your automation needs, with flexible packaging and lead material options. Request a free technical datasheet to learn more about how our products can enhance your operational efficiency.

Author Information: [Your Name] is an industrial automation specialist with 10+ years of experience in sensor technology. He focuses on helping manufacturers optimize their processes through high-performance sensing components.

References:

1. IEC 60751:2022. Industrial platinum resistance thermometers and platinum temperature sensors.

2. “Temperature Sensing in Industrial Automation” – International Society of Automation (ISA), 2024.

Xi'an Tongzida Technology Co., Ltd. est un fabricant et fournisseur de premier plan de technologies de thermistances avancées, spécialisé dans la fourniture de capteurs de température haute performance pour les applications industrielles exigeantes. Notre expertise approfondie en fabrication de microcapteurs, en technologies d'encapsulation spécifiques et en méthodes d'intégration multi-capteurs nous permet de garantir l'excellente performance et la fiabilité de nos thermistances. En tant que fournisseur de confiance de solutions de mesure de température de précision, nous proposons un système complet de thermistances, incluant les puces de capteurs, les systèmes de test et les logiciels d'analyse. N'hésitez pas à contacter nos experts techniques. ventes11@xatzd.com Discutez de vos besoins spécifiques en matière de thermistances et découvrez comment nos capacités avancées d'optimisation et de fabrication de résistances thermiques peuvent améliorer les performances et la fiabilité de votre système de mesure de température.

Learn about our latest products and discounts through SMS or email