Design and Construction of Pt100 Thin Film Sensors

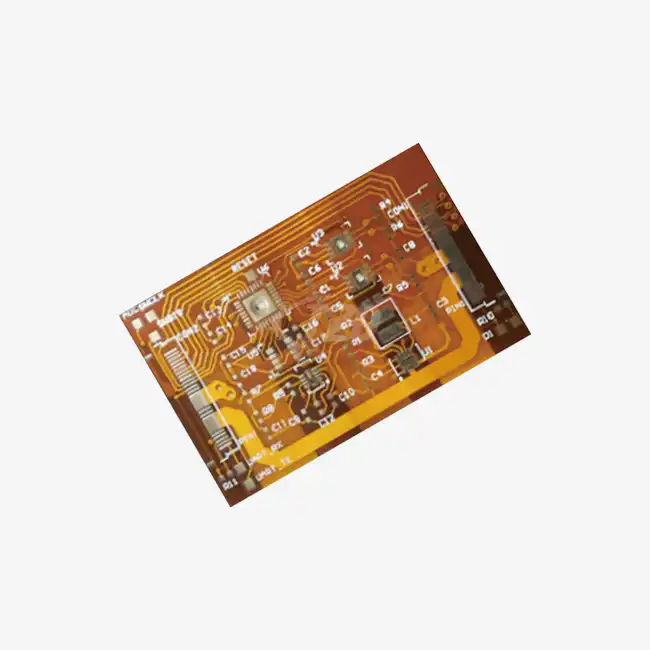

Material Composition and Fabrication Process

Pt100 Thin Film Sensors are meticulously crafted using advanced manufacturing techniques. The core of these sensors consists of a thin platinum film deposited on a ceramic substrate. This platinum layer, typically measuring just a few micrometers in thickness, is the heart of the sensor's functionality. The fabrication process involves precision sputtering or evaporation techniques to ensure uniform deposition of the platinum film.

The ceramic substrate provides mechanical stability and electrical insulation, contributing to the sensor's overall robustness. Common substrate materials include alumina or silicon, chosen for their excellent thermal properties and compatibility with thin film deposition processes. The combination of platinum and ceramic results in a sensor that can withstand harsh environmental conditions while maintaining accuracy.

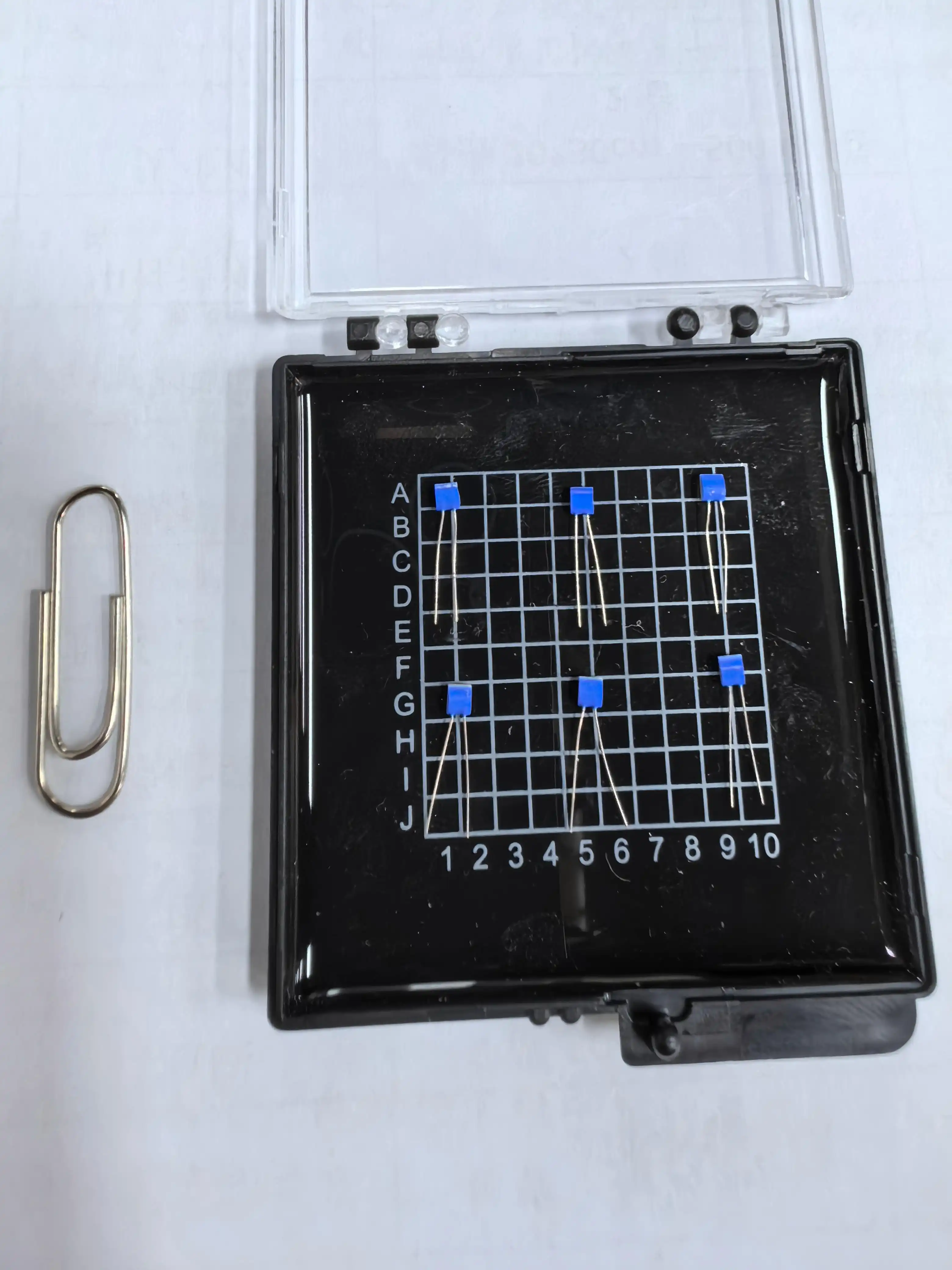

Miniaturization and Compact Design

One of the standout features of Pt100 Thin Film Sensors is their compact size. With dimensions as small as 3.2mm x 1.6mm x 0.7mm, these sensors can be integrated into applications where space is at a premium. This miniaturization is achieved without compromising performance, thanks to the precision of thin film technology.

The compact design offers several advantages: - Improved response time due to reduced thermal mass - Enhanced flexibility in sensor placement and integration - Reduced material costs and overall device footprint - Compatibility with surface mount technology for easy assembly

Terminal Configuration and Soldering Options

Pt100 Thin Film Sensors typically feature tin alloy terminals, which provide excellent electrical conductivity and solderability. These terminals are designed to withstand the rigors of industrial applications while ensuring reliable electrical connections.

For integration into electronic systems, these sensors support various soldering methods:

- Reflow soldering: Ideal for high-volume production

- Wave soldering: Suitable for through-hole mounting applications

- High-temperature solder paste: Recommended for optimal performance

The recommended soldering temperature range of 230-240°C ensures proper bonding without compromising the sensor's integrity. This versatility in soldering options makes Pt100 Thin Film Sensors adaptable to different manufacturing processes and assembly requirements.

Performance Characteristics of Pt100 Thin Film Sensors

Temperature Coefficient and Measurement Range

Pt100 Thin Film Sensors boast a temperature coefficient (TCR) of 3850 ppm/°C, adhering to the IEC60751 standard. This high TCR value ensures excellent sensitivity to temperature changes, allowing for precise measurements across a wide range.

The typical temperature measurement range for these sensors spans from -50°C to +200°C, making them suitable for diverse applications. However, advanced models can extend this range from -200°C to +850°C, catering to extreme temperature environments in industries such as aerospace and cryogenics.

Accuracy and Long-Term Stability

Accuracy is paramount in temperature sensing, and Pt100 Thin Film Sensors excel in this aspect. With an accuracy of ± 0.01 Ω, these sensors provide highly reliable temperature readings. This precision is crucial in applications where even small temperature deviations can have significant consequences.

Long-term stability is another hallmark of Pt100 Thin Film Sensors. They exhibit a resistance drift of ≤±0.06% of R₀°C after 1000 hours at 200°C, demonstrating exceptional stability over time. This translates to consistent performance and reduced need for recalibration, saving time and resources in industrial settings.

Response Time and Environmental Resilience

Pt100 Thin Film Sensors are renowned for their rapid response times, with some models achieving response times as low as 0.05 seconds. This quick reaction to temperature changes is invaluable in dynamic environments where real-time monitoring is essential.

These sensors also demonstrate remarkable environmental resilience:

- Vibration resistance up to 40g

- Impact resistance up to 100g

- Ability to withstand harsh industrial conditions

This robustness makes Pt100 Thin Film Sensors ideal for use in challenging applications such as automotive, aerospace, and heavy machinery, where reliability under stress is crucial.

Applications and Industry Standards

Diverse Industrial Applications

The versatility of Pt100 Thin Film Sensors makes them indispensable across various industries:

- Industrial Process Control: Monitoring and regulating temperatures in manufacturing processes

- Medical Equipment: Ensuring precise temperature control in diagnostic and therapeutic devices

- Automotive: Engine temperature monitoring and climate control systems

- Aerospace: Temperature sensing in aircraft engines and cabin environmental systems

- Food and Beverage: Maintaining optimal temperatures during production and storage

- HVAC Systems: Accurate temperature control in heating, ventilation, and air conditioning

The wide temperature range, high accuracy, and rapid response times of these sensors make them adaptable to the unique requirements of each industry, contributing to improved efficiency and product quality.

Compliance with International Standards

Pt100 Thin Film Sensors are designed and manufactured to meet stringent international standards, ensuring reliability and interoperability. Key certifications and standards include:

- ISO9001 Quality Management System: Ensuring consistent quality in manufacturing processes

- RoHS Compliance: Meeting environmental standards for hazardous substance restriction

- CE Certification: Conforming to European health, safety, and environmental protection standards

- IEC60751: Compliance with international standards for industrial platinum resistance thermometers

Adherence to these standards not only guarantees the quality of Pt100 Thin Film Sensors but also facilitates their integration into global supply chains and diverse applications worldwide.

Customization and Future Trends

The field of Pt100 Thin Film Sensors continues to evolve, with manufacturers offering customization options to meet specific industry needs. These include:

- Multiple size options ranging from 1.2mm to 4.0mm

- Various lead materials such as platinum nickel, silver nickel, and pure platinum

- Specialized coatings for enhanced protection in corrosive environments

- Integration with smart sensors and IoT platforms for remote monitoring and data analytics

Future trends in Pt100 Thin Film Sensor technology are likely to focus on further miniaturization, increased accuracy, and enhanced integration with digital systems. The development of self-calibrating sensors and those with built-in diagnostics capabilities is also on the horizon, promising even greater reliability and ease of use in industrial applications.

Conclusion

Pt100 Thin Film Sensors represent a pinnacle in temperature sensing technology, offering a unique combination of accuracy, reliability, and versatility. Their compact design, wide temperature range, and robust performance make them ideal for a multitude of applications across various industries.

As technology continues to advance, these sensors will undoubtedly play an increasingly crucial role in ensuring precise temperature control and monitoring in both current and emerging fields. For more information on Pt100 Thin Film Sensors and how they can benefit your specific application, please contact us at sales11@xatzd.com. Our team of experts is ready to assist you in finding the perfect temperature sensing solution for your needs.