Grasping Pt100 Temperature Sensors and Their Characteristics

Pt100 temperature sensors are resistance temperature detectors (RTDs) that utilize the principle of electrical resistance change in platinum wire as temperature varies. These sensors are named "Pt100" because they are made of platinum (Pt) and have a resistance of 100 ohms at 0°C. The platinum element in Pt100 sensors exhibits a highly linear and predictable resistance-temperature relationship, making them ideal for precise temperature measurements.

One of the key characteristics of Pt100 sensors is their temperature coefficient of resistance (TCR), which is typically 3850 ppm/°C for industrial-grade sensors. This means that for every degree Celsius change in temperature, the resistance of the sensor changes by 0.385 ohms. This predictable behavior allows for accurate temperature calculations based on the measured resistance.

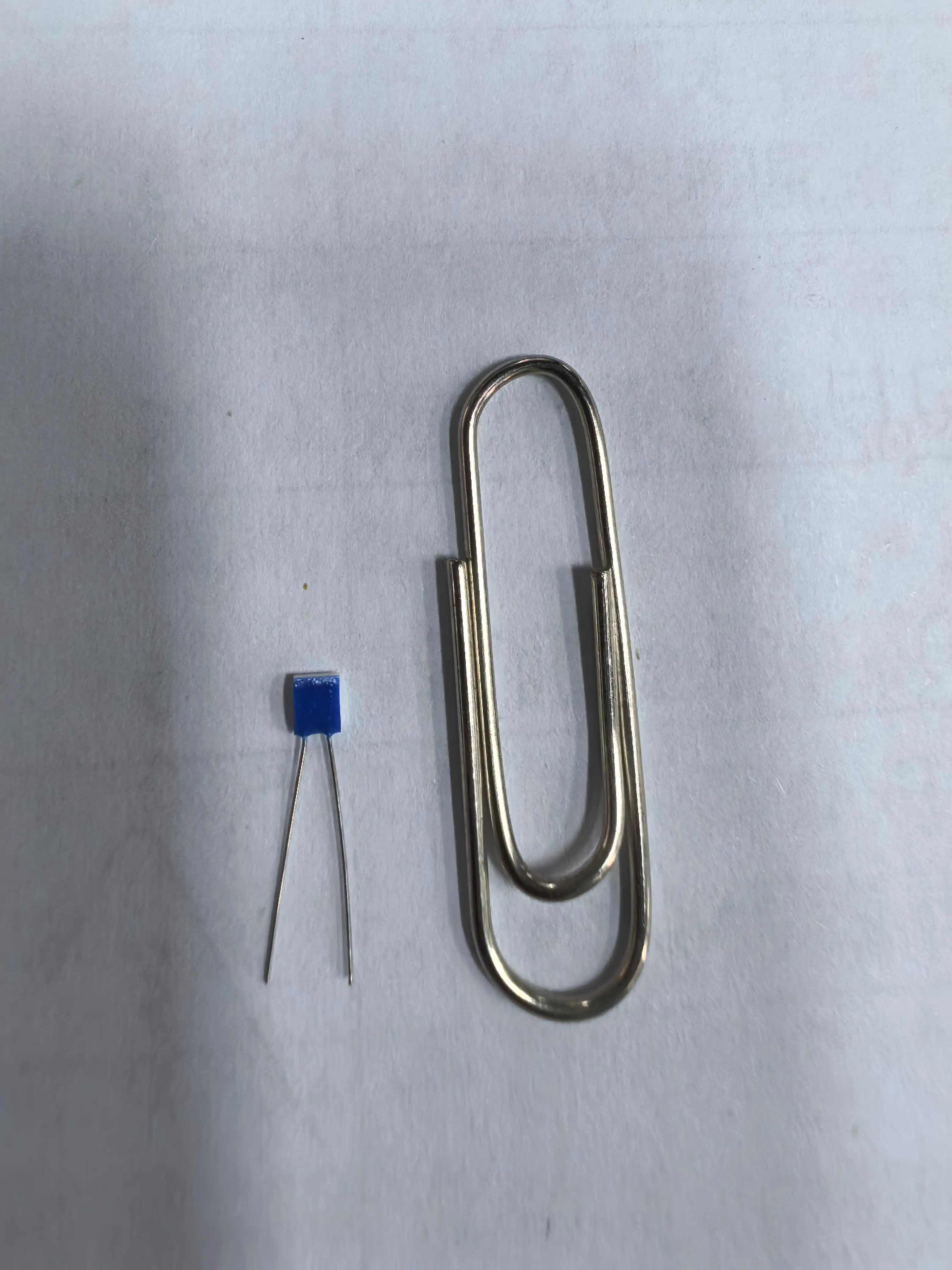

Pt100 sensors are available in various configurations, including wire-wound and thin-film constructions. Thin-film Pt100 sensors, such as those with dimensions of 3.2mm x 1.6mm x 0.7mm, offer advantages in terms of size, response time, and vibration resistance. These sensors can cover a wide temperature measurement range, often from -50°C to +200°C or even broader ranges like -200°C to +850°C, depending on the specific design and construction.

Accuracy and Stability of Pt100 Sensors

The accuracy of Pt100 sensors is one of their most significant advantages. High-quality Pt100 sensors can achieve accuracies of ±0.01 Ω or better, translating to temperature measurement accuracies of fractions of a degree Celsius. This level of precision is crucial for many industrial processes where tight temperature control is required.

Long-term stability is another critical factor in industrial applications. Premium Pt100 sensors exhibit excellent stability, with resistance drift as low as ±0.06% of R₀°C after 1000 hours at 200°C. This stability ensures reliable measurements over extended periods, reducing the need for frequent recalibration and minimizing process disruptions.

Integrating Pt100 Sensors with PLC Systems

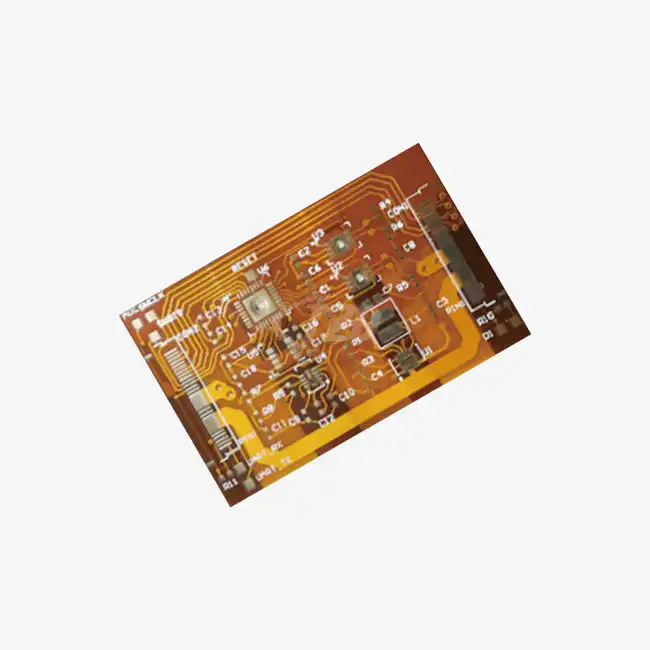

The integration of Pt100 temperature sensors with PLC systems involves several considerations to ensure accurate and reliable temperature measurements. PLCs typically work with standardized input signals, such as 4-20 mA or 0-10 V, while Pt100 sensors provide a resistance output that changes with temperature. Therefore, signal conditioning is necessary to convert the sensor's resistance into a format compatible with the PLC's input modules.

There are several methods to interface Pt100 sensors with PLCs:

Transmitter-Based Integration

One common approach is to use a temperature transmitter that converts the Pt100 sensor's resistance into a standard analog signal (e.g., 4-20 mA). The transmitter can be mounted close to the sensor or integrated into the sensor assembly. This method offers advantages such as noise immunity over long distances and compatibility with standard PLC analog input modules.

Direct Connection with RTD Input Modules

Many modern PLCs offer specialized RTD input modules that can directly interface with Pt100 temperature sensors. These modules handle the necessary signal conditioning and linearization internally, simplifying the integration process. When using such modules, it's important to consider the wiring configuration (2-wire, 3-wire, or 4-wire) to compensate for lead wire resistance and ensure measurement accuracy.

Custom Signal Conditioning Circuits

For applications requiring high precision or special features, custom signal conditioning circuits can be designed. These circuits may include constant current sources, amplifiers, and analog-to-digital converters tailored to the specific requirements of the application.

Optimizing Pt100 Sensor Performance in PLC-Based Systems

To maximize the performance of Pt100 sensors in PLC-based systems, several factors should be considered:

Wiring and Shielding

Proper wiring practices are crucial for accurate temperature measurements. Using shielded cables and implementing appropriate grounding techniques can help minimize electromagnetic interference and noise pickup, especially in industrial environments with high electromagnetic noise levels.

The choice of wiring configuration (2-wire, 3-wire, or 4-wire) depends on the required accuracy and the distance between the sensor and the PLC. For high-precision applications or long cable runs, 4-wire configurations are preferred as they effectively compensate for lead wire resistance.

Calibration and Maintenance

Regular calibration of the Pt100 temperature sensors and associated signal conditioning equipment is essential to maintain measurement accuracy over time. Implementing a calibration schedule based on the application's requirements and the sensor's specifications helps ensure reliable temperature measurements.

Proper maintenance practices, such as protecting sensors from mechanical stress and exposure to contaminants, can significantly extend their operational life and maintain their performance characteristics.

Software Considerations

On the PLC side, implementing appropriate scaling and linearization algorithms is crucial for converting the raw sensor data into accurate temperature values. Many modern PLCs offer built-in functions for RTD linearization, simplifying the programming process.

Additionally, implementing features such as filtering, averaging, and alarm thresholds in the PLC program can enhance the overall performance of the temperature measurement system and provide more robust control capabilities.

Conclusion

Pt100 temperature sensors are highly compatible with PLC systems, offering excellent accuracy, stability, and versatility for industrial temperature measurement applications. By carefully considering the integration method, optimizing the sensor installation, and implementing proper maintenance practices, engineers can harness the full potential of Pt100 sensors in PLC-based control systems. For more information on high-performance Pt100 sensors and their integration with PLCs, please contact us at sales11@xatzd.com.