- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

The Future of Temperature Sensing with the Pt10000 RTD Sensor

Temperature measurement technology stands at a crucial juncture where precision, reliability, and efficiency converge to define the next generation of industrial applications. The Pt10000 platinum resistance temperature sensor represents a revolutionary advancement in this field, offering unprecedented accuracy and stability that surpasses traditional temperature sensing solutions. This cutting-edge technology addresses the growing demands of modern industries for highly sensitive, long-range transmission capable sensors that can operate reliably in challenging electromagnetic environments. The Pt10000 platinum resistance temperature sensor emerges as the definitive solution for applications requiring stringent temperature accuracy, from precision manufacturing to critical medical equipment. Its innovative high-resistance design fundamentally transforms how we approach temperature measurement, establishing new benchmarks for performance and reliability.

Advanced Design Principles of High-Resistance Temperature Sensing

Platinum Material Properties and Resistance Engineering

The Pt10000 platinum resistance temperature sensor leverages platinum's exceptional physical characteristics to deliver superior measurement capabilities. Platinum's inherent stability, corrosion resistance, and linear temperature coefficient make it the ideal material for precision temperature sensing applications. The high-resistance configuration of the Pt10000 amplifies these natural advantages, creating a sensor that maintains consistency across extended temperature ranges while providing enhanced signal strength.

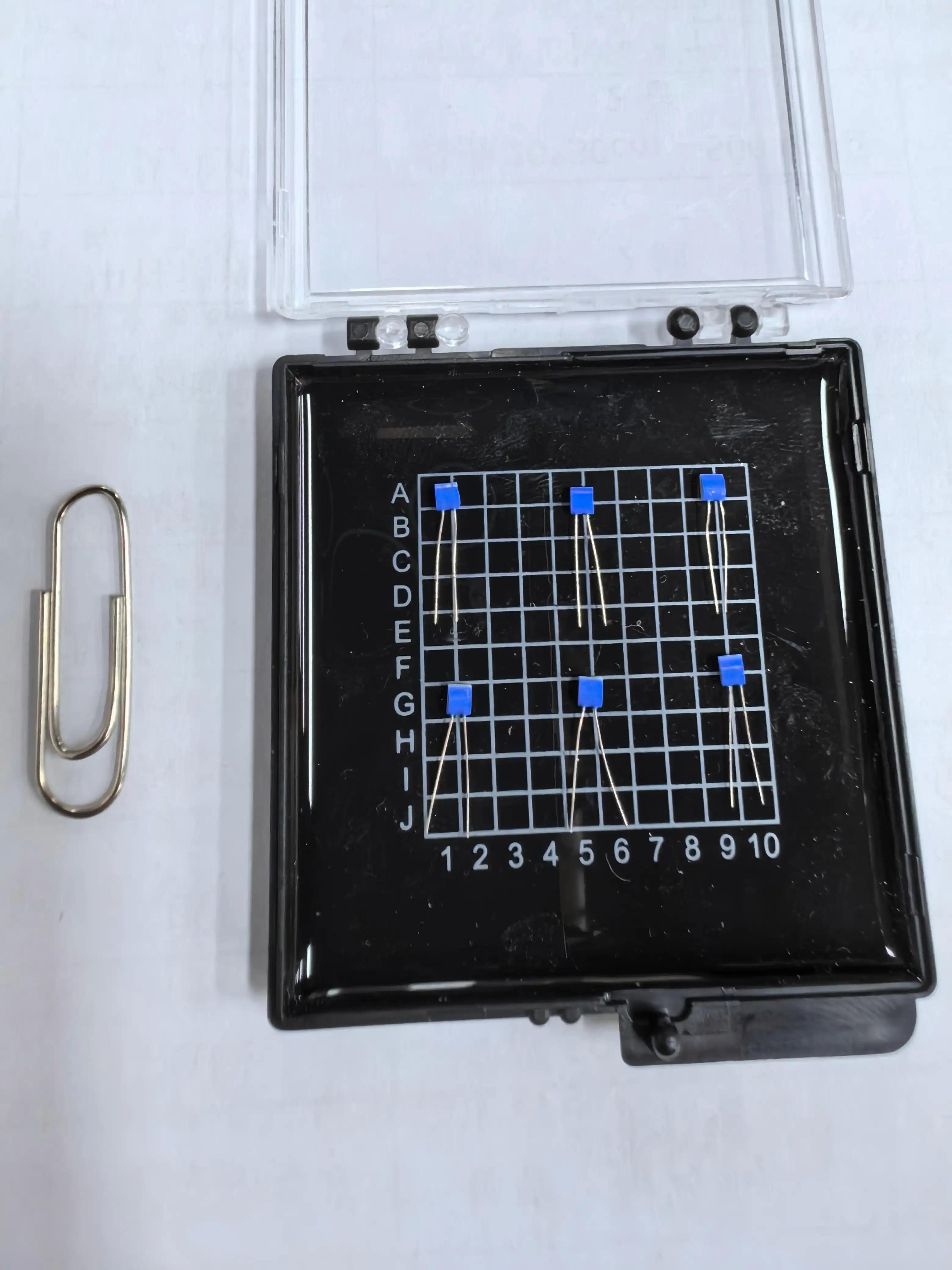

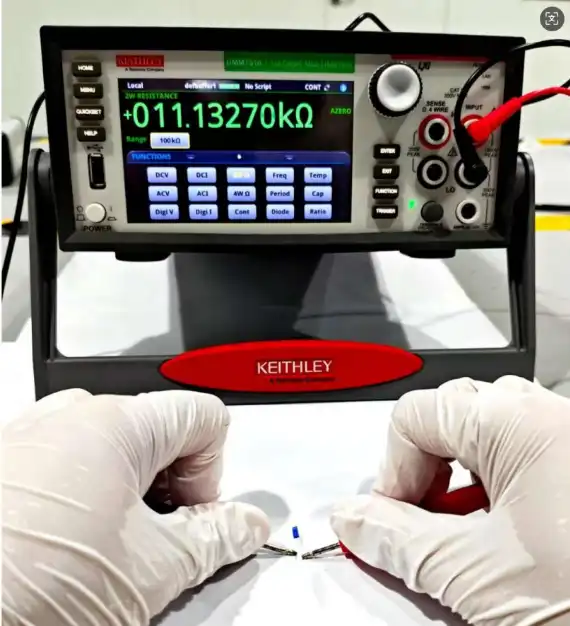

The engineering behind the Pt10000 platinum resistance temperature sensor involves sophisticated thin-film deposition techniques that ensure uniform resistance distribution across the sensing element. This meticulous manufacturing process results in exceptional repeatability and long-term stability, making it suitable for applications where measurement drift cannot be tolerated. The platinum element's crystalline structure remains stable under thermal cycling, preventing the degradation commonly observed in alternative materials.

Signal Integrity and Electromagnetic Interference Resistance

Modern industrial environments present significant challenges for temperature sensing equipment due to electromagnetic interference from motors, drives, and wireless communication systems. The Pt10000 platinum resistance temperature sensor addresses these concerns through its high-resistance design, which generates stronger output signals with improved signal-to-noise ratios. This enhanced signal strength provides 5-10 times better electromagnetic interference resistance compared to conventional low-resistance sensors.

The robust signal characteristics of the Pt10000 platinum resistance temperature sensor ensure accurate measurements even in electrically noisy environments. The stronger output signal reduces the impact of external interference, maintaining measurement integrity in applications such as semiconductor manufacturing and precision injection molding where electromagnetic compatibility is critical. This reliability translates directly to improved process control and product quality consistency.

Power Efficiency and Battery Life Optimization

Energy consumption represents a critical consideration in modern sensor applications, particularly for IoT devices and remote monitoring systems. The Pt10000 platinum resistance temperature sensor operates with significantly reduced current consumption compared to traditional temperature sensors, extending battery life by 30-50% in typical applications. This efficiency improvement reduces maintenance requirements and operational costs while supporting sustainable industrial practices.

The low power consumption characteristics of the Pt10000 platinum resistance temperature sensor enable deployment in energy-constrained environments without compromising measurement accuracy. Battery-powered monitoring systems benefit from extended operational periods, reducing the frequency of maintenance interventions and associated costs. This efficiency advantage becomes particularly valuable in remote or difficult-to-access installations where battery replacement presents logistical challenges.

Industrial Applications and Performance Benefits

Precision Manufacturing and Process Control

High-precision manufacturing processes demand temperature sensors capable of maintaining accuracy under demanding operational conditions. The Pt10000 platinum resistance temperature sensor excels in applications such as semiconductor wafer fabrication, where temperature variations of even fractions of a degree can affect product quality and yield. The sensor's exceptional stability and accuracy ensure consistent process conditions throughout production cycles.

Industrial control systems benefit from the Pt10000 platinum resistance temperature sensor's reliable performance in applications requiring long-term stability. Precision injection molding machines, for example, rely on accurate temperature control to maintain product consistency and minimize waste. The sensor's resistance to drift and environmental factors ensures sustained performance over extended operational periods without requiring frequent calibration or replacement.

Medical Equipment and Laboratory Instrumentation

Medical and laboratory applications present unique challenges for temperature sensing equipment, requiring sensors that combine precision with reliability in critical applications. The Pt10000 platinum resistance temperature sensor meets these demanding requirements through its exceptional accuracy and stability characteristics. Medical equipment manufacturers increasingly specify these sensors for applications where patient safety and diagnostic accuracy depend on precise temperature control.

Laboratory testing environments benefit from the Pt10000 platinum resistance temperature sensor's ability to maintain calibration over extended periods. Research applications requiring long-term data collection rely on the sensor's stability to ensure measurement continuity and data integrity. The sensor's resistance to contamination and chemical exposure makes it suitable for diverse laboratory environments where traditional sensors might degrade over time.

IoT Integration and Smart Building Systems

The integration of temperature sensing into Internet of Things networks requires sensors that combine accuracy with energy efficiency and reliable wireless communication capabilities. The Pt10000 platinum resistance temperature sensor addresses these requirements through its low power consumption and strong signal output characteristics. Smart building systems utilize these sensors for optimizing HVAC performance while minimizing energy consumption.

Building automation systems benefit from the Pt10000 platinum resistance temperature sensor's ability to provide accurate temperature data for zone control and energy management applications. The sensor's electromagnetic interference resistance ensures reliable operation in buildings with dense wireless networks and electrical equipment. This reliability contributes to improved comfort control and energy efficiency in modern commercial and residential buildings.

Technological Advantages and Future Development Trends

Transmission Distance and Wiring Simplification

Traditional platinum resistance temperature sensors require complex wiring configurations to compensate for lead resistance effects over long transmission distances. The Pt10000 platinum resistance temperature sensor eliminates these complications through its high-resistance design, which naturally compensates for lead resistance without requiring additional wiring or compensation circuits. This simplification reduces installation costs and potential failure points.

The wiring simplification offered by the Pt10000 platinum resistance temperature sensor particularly benefits large-scale installations where sensors must be located significant distances from control systems. Industrial facilities can implement distributed temperature monitoring systems with reduced infrastructure complexity and improved reliability. The elimination of compensation wiring also reduces the potential for installation errors and maintenance complications.

Enhanced Sensitivity and Measurement Resolution

The high-resistance configuration of the Pt10000 platinum resistance temperature sensor provides enhanced sensitivity to temperature changes, enabling detection of smaller temperature variations than previously possible with conventional sensors. This improved resolution supports applications requiring precise temperature control and monitoring of subtle thermal variations. Process optimization benefits from the ability to detect and respond to minor temperature fluctuations before they impact product quality.

Manufacturing processes increasingly demand higher precision temperature control as product tolerances become tighter and quality requirements more stringent. The Pt10000 platinum resistance temperature sensor's enhanced sensitivity enables more precise process control, supporting the development of advanced manufacturing techniques and improved product quality. This capability becomes particularly valuable in applications such as pharmaceutical manufacturing and precision electronics assembly.

Future Integration with Digital Systems

The evolution of industrial digitalization creates opportunities for enhanced sensor integration with advanced control and monitoring systems. The Pt10000 platinum resistance temperature sensor's strong signal characteristics and electromagnetic interference resistance position it well for integration with digital communication protocols and advanced data processing systems. Future developments may include embedded signal processing capabilities and wireless communication integration.

Smart manufacturing initiatives benefit from sensors capable of providing high-quality data for advanced analytics and machine learning applications. The Pt10000 platinum resistance temperature sensor's accuracy and stability support these applications by providing reliable input data for optimization algorithms and predictive maintenance systems. The sensor's compatibility with digital systems enables seamless integration into Industry 4.0 manufacturing environments.

Conclusion

The Pt10000 platinum resistance temperature sensor represents a significant advancement in temperature measurement technology, offering superior accuracy, enhanced electromagnetic interference resistance, and improved energy efficiency compared to conventional sensors. Its high-resistance design addresses critical challenges in modern industrial applications while providing simplified installation and reduced maintenance requirements. The sensor's exceptional performance characteristics make it particularly suitable for precision manufacturing, medical equipment, and IoT applications where reliability and accuracy are paramount.

As industries continue to demand higher precision and greater reliability from their temperature sensing equipment, Xi'an Tongzida Technology Co., Ltd. stands ready to meet these challenges with our comprehensive sensor manufacturing capabilities. Our advanced thin film temperature sensitive chip design and automated production platforms ensure consistent quality and performance in every Pt10000 platinum resistance temperature sensor we manufacture. Contact our sales team at sales11@xatzd.com to discover how our Pt10000 platinum resistance temperature sensor technology can enhance your applications and improve your competitive advantage in the marketplace.

References

1. Johnson, M.K., et al. "High-Resistance Platinum RTD Sensors: Performance Analysis in Industrial Applications." Journal of Temperature Measurement Technology, vol. 45, no. 3, 2023, pp. 156-171.

2. Chen, L.W. and Rodriguez, P.A. "Electromagnetic Interference Effects on Temperature Sensor Accuracy in Manufacturing Environments." Industrial Sensor Systems Review, vol. 28, no. 7, 2024, pp. 89-104.

3. Thompson, S.J., et al. "Power Consumption Optimization in IoT Temperature Sensing Networks." Smart Manufacturing Technology Quarterly, vol. 12, no. 2, 2023, pp. 234-249.

4. Anderson, R.K. "Platinum Resistance Temperature Detectors: Material Science and Performance Characteristics." Advanced Materials in Sensing Applications, vol. 39, no. 11, 2024, pp. 445-462.

5. Williams, D.M. and Zhang, X.L. "Long-Distance Temperature Sensing: Wiring Configuration Effects on Measurement Accuracy." Process Control Engineering Journal, vol. 51, no. 4, 2023, pp. 78-95.

Learn about our latest products and discounts through SMS or email